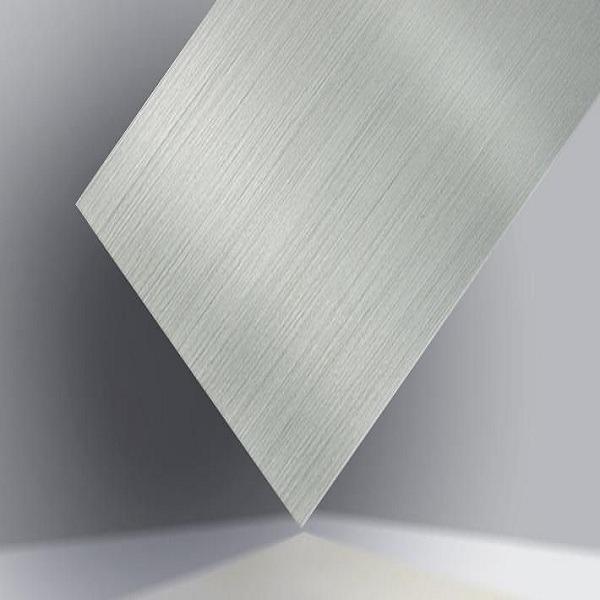

What Is a Good CNC Milling Speed for Aluminum?

There's no single "good" CNC milling speed for aluminum because it depends on several factors that can influence the machining process. Here's a breakdown of the key considerations:

l Aluminum type: Different aluminum alloys have varying degrees of hardness and machinability. Softer alloys like 1100 allow for faster cutting speeds compared to harder ones like 6061-T6.

l Cutting tool material and geometry: The type of tool material (carbide, high-speed steel) and its design (number of flutes, diameter) will affect how well it handles heat and chip evacuation, impacting the ideal speed.

l Desired surface finish: A smooth finish requires a slower cutting speed to minimize tool marks and vibrations. Conversely, roughing cuts can tolerate higher speeds for faster material removal.

l Machine rigidity and power: A rigid machine frame and powerful spindle motor allow for higher cutting speeds without sacrificing precision or finish quality.

Here's a general guideline to get you started:

l For most aluminum alloys with carbide tools, a starting point for cutting speed (Vc) is between 60 and 120 meters per minute (m/min).

l High-speed machining (HSM) with specialized tools can push Vc up to 400 m/min for certain aluminum types.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Игры

- Gardening

- Health

- Главная

- Literature

- Music

- Networking

- Другое

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness