Intelligent Li-Metal Solid-State Battery Pilot Lines Emerge as Key Milestone in EV Battery Technology

The automotive industry is on the brink of a significant transformation, driven by the urgent need for more efficient and sustainable energy storage solutions. Among the most promising advancements in this field are intelligent lithium-metal solid-state battery (LMSB) pilot lines, which are poised to revolutionize electric vehicle (EV) technology. These pilot lines not only enhance battery performance but also streamline production processes, making them a crucial milestone in the evolution of battery technology. Mikrouna, a leading provider of comprehensive solutions for Intelligent Li-Metal Solid-State Battery Pilot Lines. This article explores the significance of these intelligent pilot lines and their potential impact on the future of electric mobility.

Understanding Lithium-Metal Solid-State Batteries

Lithium-metal solid-state batteries represent a significant leap forward from traditional lithium-ion batteries. By utilizing a lithium metal anode and a solid electrolyte, these batteries offer several advantages, including:

- Higher Energy Density: LMSBs can potentially double the energy density of conventional batteries, allowing EVs to travel further on a single charge.

- Improved Safety: The solid electrolyte reduces the risk of leaks and fires, which are common issues with liquid electrolytes found in traditional batteries.

- Faster Charging Times: With advancements in solid-state technology, charging times can be significantly reduced, addressing one of the major concerns for EV users.

The Significance of Pilot Lines in Battery Development

Pilot lines serve as essential testing grounds for new technologies, allowing manufacturers to scale up from laboratory prototypes to full-scale production. In the context of LMSSBs, pilot lines enable researchers to validate manufacturing processes, optimize performance, and identify potential challenges before committing to large-scale production. This step is critical, as transitioning directly from lab-scale to commercial-scale production often leads to unforeseen issues that can derail timelines and inflate costs.

The establishment of intelligent pilot lines incorporates advanced technologies, such as automation and data analytics, to enhance the efficiency and reliability of the production process. These lines allow for real-time monitoring and adjustments, ensuring that the manufacturing environment is optimized for producing high-quality LMSSBs.

Mikrouna’s Role in Supporting LMSSB Development

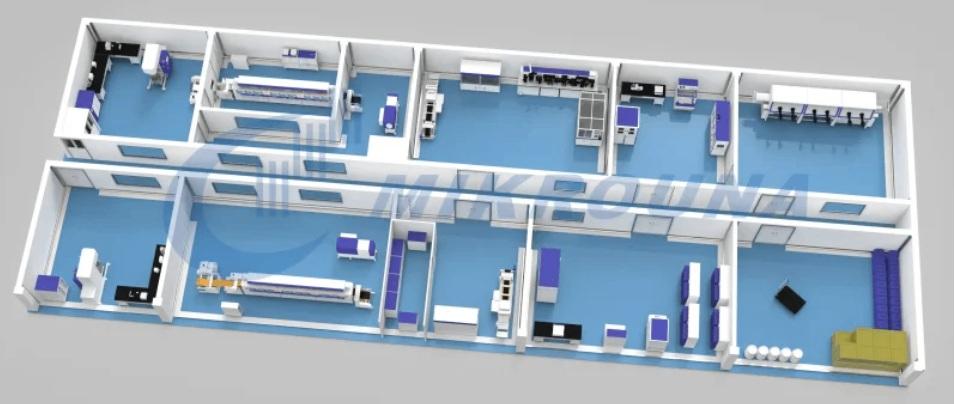

Mikrouna is at the forefront of providing comprehensive solutions for lithium-metal battery research and development. Their offerings include state-of-the-art gas purification gloveboxes and automated production lines designed specifically for battery manufacturing. These gloveboxes create a controlled environment essential for handling air-sensitive materials like lithium metal, which is critical for the integrity and performance of LMSSBs.

Mikrouna’s automated production lines further enhance the efficiency of LMSSB pilot lines by streamlining processes such as lithium metal preparation and electrode formation. By integrating advanced automation into the production workflow, Mikrouna helps manufacturers reduce labor costs, minimize human error, and increase overall productivity.

Implications for Electric Vehicle Adoption

The emergence of intelligent lithium-metal solid-state battery pilot lines has significant implications for the electric vehicle market:

1. Increased Range and Performance: With higher energy densities and faster charging capabilities, LMSBs can enhance the overall performance of electric vehicles, making them more attractive to consumers.

2. Lower Costs: As production processes become more efficient and scalable, the cost of manufacturing solid-state batteries is expected to decrease. This reduction in cost can lead to more affordable EVs, increasing accessibility for a broader range of consumers.

3. Sustainability: The shift towards solid-state batteries aligns with global sustainability goals. By reducing reliance on traditional battery technologies and improving recycling processes, LMSBs can contribute to a more sustainable automotive industry.

Challenges and Considerations

While the development of intelligent pilot lines for lithium-metal solid-state batteries is promising, several challenges remain:

- Technical Hurdles: The transition from traditional battery technologies to solid-state solutions involves overcoming technical challenges, such as improving the conductivity of solid electrolytes and ensuring the stability of lithium metal anodes.

- Investment and Infrastructure: Establishing intelligent pilot lines requires significant investment in infrastructure and technology. Manufacturers must be willing to invest in these advancements to reap the long-term benefits.

- Regulatory Compliance: As new technologies emerge, regulatory frameworks must adapt to ensure safety and performance standards are met. Collaboration between manufacturers and regulatory bodies will be essential in navigating this landscape.

Conclusion

Intelligent lithium-metal solid-state battery pilot lines represent a key milestone in the evolution of battery technology and the electric vehicle market. By leveraging advanced technologies such as AI and machine learning, these pilot lines enhance production efficiency, improve battery performance, and pave the way for more sustainable energy solutions. As manufacturers continue to invest in these innovations, the future of electric mobility looks promising, with the potential for longer ranges, faster charging times, and more affordable electric vehicles. The journey towards a cleaner, more efficient transportation landscape is underway, and intelligent pilot lines are at the forefront of this exciting transformation.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Startseite

- Literature

- Musik

- Networking

- Andere

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness