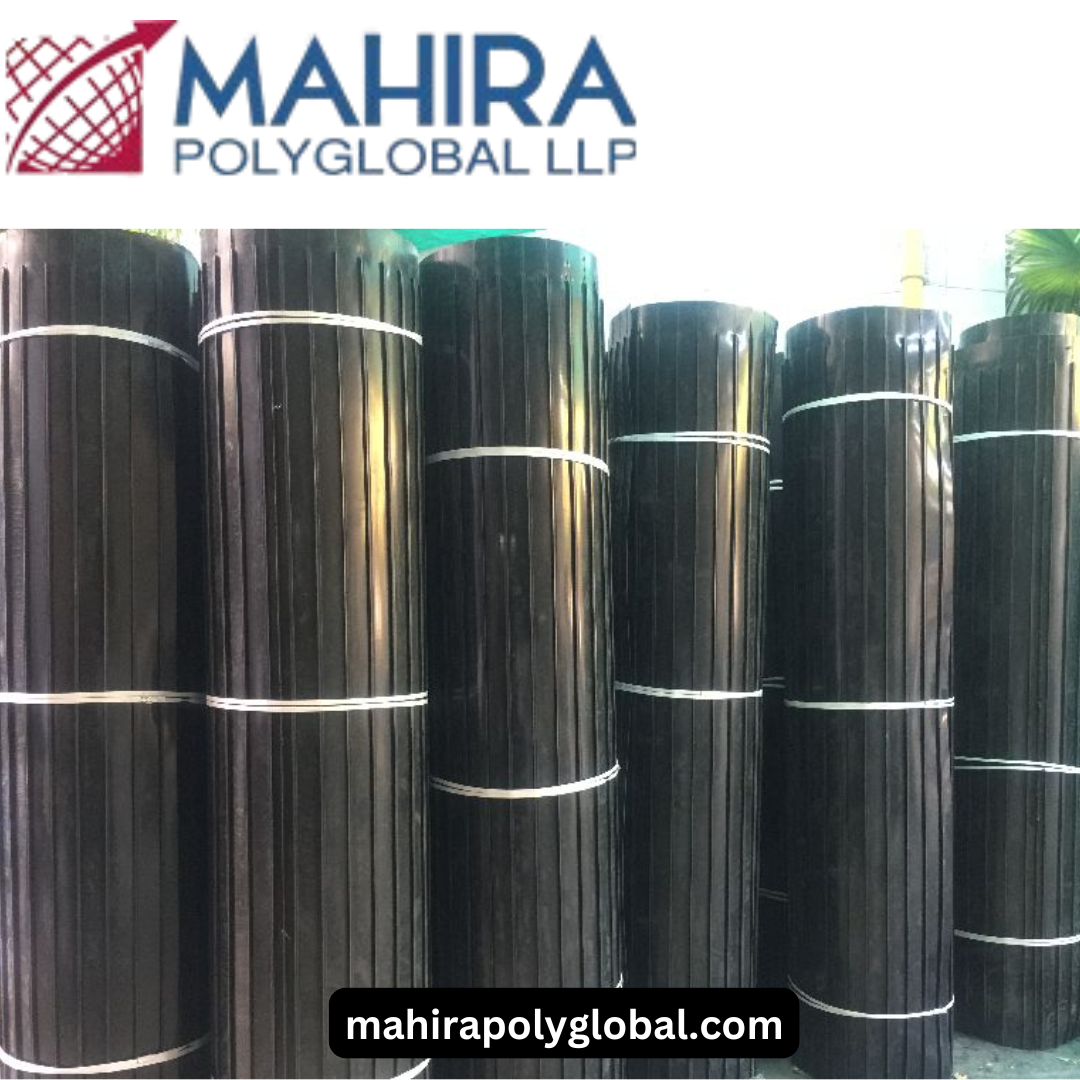

HDPE T-Rib Liner Sheets: A Comprehensive Guide to Applications, Benefits, and Installation

Introduction

HDPE (High-Density Polyethylene) T-Rib liner sheets have revolutionized the industrial world, offering unmatched protection and durability for various applications. Whether used in tunnels, sewage systems, or water treatment plants, these sheets provide long-lasting protection against corrosion, abrasion, and chemical damage. As industries seek cost-effective solutions for lining and safeguarding surfaces, T-Rib HDPE Liner Sheets have become a top choice.

In this article, Mahira Polyglobal LLP delve into the world of HDPE T-Rib liner sheets, covering their unique characteristics, applications, benefits, and installation process. We’ll also address frequently asked questions (FAQs) to help you better understand this versatile material.

What Are HDPE T-Rib Liner Sheets?

HDPE T-Rib liner sheets are specially designed high-density polyethylene sheets that feature a T-shaped ribbed surface on one side. This ribbed surface allows for a secure mechanical anchorage into concrete, making the liner highly effective in preventing seepage and protecting the structure from corrosion and wear. The smooth side of the liner sheet is typically exposed to resist chemicals, corrosion, and abrasion, offering high durability and long-lasting performance.

Key Characteristics of HDPE T-Rib Liner Sheets

HDPE T-Rib liner sheets offer several unique properties that make them ideal for a variety of industrial and construction applications. Here are some key characteristics:

-

High Corrosion Resistance: These liner sheets are highly resistant to chemicals, acids, alkalis, and other corrosive agents, making them perfect for use in environments exposed to harsh chemicals.

-

Abrasion Resistance: HDPE is known for its toughness, and T-Rib liner sheets provide excellent resistance to wear and abrasion, extending the life of the concrete or metal surfaces they protect.

-

Waterproof: HDPE liner sheets are highly effective at preventing water infiltration, making them ideal for tunnels, sewage systems, and water treatment plants where waterproofing is essential.

-

High Tensile Strength: With impressive tensile strength, these sheets can withstand mechanical stress and heavy loads without tearing or deforming.

-

UV and Weather Resistance: HDPE T-Rib liner sheets are resistant to UV rays and other environmental factors, ensuring their durability even in outdoor applications.

-

Temperature Tolerance: They can handle a wide range of temperatures, making them suitable for use in both hot and cold climates.

Applications of HDPE T-Rib Liner Sheets

The HDPE T-Rib Liner Sheets Installation are used across multiple industries, providing reliable protection for structures in need of corrosion, chemical, and water resistance. Some of the most common applications include:

1. Sewage Systems and Wastewater Treatment Plants

HDPE T-Rib liner sheets are extensively used in sewage systems and wastewater treatment plants. Their ability to resist corrosive chemicals, as well as their waterproofing properties, make them ideal for these harsh environments.

2. Tunnels and Underground Constructions

In tunnel construction, the primary concern is protecting the structure from water infiltration and corrosion. HDPE T-Rib liner sheets act as an effective barrier to water, chemicals, and other damaging agents, ensuring the longevity of underground constructions.

3. Chemical Storage Tanks and Industrial Plants

Chemical plants and industrial facilities often require protective linings that can withstand corrosive substances. HDPE T-Rib liner sheets offer an affordable and efficient solution for lining storage tanks, chemical containment areas, and other industrial structures.

4. Marine Structures

In marine applications, constant exposure to saltwater can cause severe corrosion of structures. HDPE T-Rib liner sheets are highly resistant to saltwater and other corrosive elements, making them perfect for protecting marine structures like docks and underwater pipelines.

5. Landfills and Solid Waste Containment

HDPE T-Rib liners are also used in landfills to prevent the leaching of toxic chemicals into the ground and water supply. Their high chemical resistance and durability make them ideal for waste containment applications.

Benefits of Using HDPE T-Rib Liner Sheets

The benefits of HDPE T-Rib liner sheets extend far beyond their durability and corrosion resistance. Here’s why they are a preferred choice in various industries:

1. Cost-Effective Solution

The long-lasting nature of HDPE T-Rib liner sheets translates to cost savings over time. With minimal maintenance requirements and a long lifespan, these liners reduce the need for frequent repairs or replacements.

2. Quick and Easy Installation

Thanks to the T-Rib design, these liners are easy to install and securely anchor into concrete. This reduces labor costs and installation time.

3. Environmentally Friendly

HDPE is a recyclable material, making T-Rib liners a more sustainable choice for industries looking to minimize their environmental footprint.

4. Customizable

HDPE T-Rib liner sheets are available in various thicknesses and sizes to suit specific project requirements. Custom fabrication ensures that the liners meet the exact needs of the application.

5. Reliable Protection Against Leakage

In water containment and wastewater treatment applications, leakage can be a major concern. HDPE T-Rib liner sheets provide reliable waterproofing, ensuring that liquids stay contained and do not seep through to surrounding areas.

Installation Process for HDPE T-Rib Liner Sheets

Proper installation of HDPE T-Rib liner sheets is critical to their performance and longevity. Here’s an outline of the typical installation process:

-

Surface Preparation: The surface to be lined must be cleaned and free from any debris, oil, or dust that could interfere with adhesion.

-

Positioning the Liner: The T-Rib side of the liner sheet is positioned against the concrete surface. The sheets are laid out in sections to cover the area that requires protection.

-

Anchoring the Liner: The T-shaped ribs on the liner provide mechanical anchorage into the concrete. As the concrete is poured, the ribs embed into the structure, ensuring a strong bond.

-

Seam Welding: To ensure a completely waterproof barrier, the seams between adjacent liner sheets are welded using specialized equipment. This creates a seamless, leak-proof surface.

-

Quality Inspection: Once installation is complete, the lined area is inspected for any defects or weak points, ensuring that the installation meets industry standards.

Conclusion

The HDPE T-Rib Sheet Price are a versatile, cost-effective, and durable solution for industries requiring protection from water, chemicals, and corrosion. Their unique ribbed design allows for easy installation in concrete structures, providing reliable protection in applications ranging from sewage systems to marine installations. By choosing HDPE T-Rib liner sheets, industries can ensure long-lasting performance and reduced maintenance costs, making them a preferred choice for various lining applications.

Whether you are involved in construction, wastewater management, or chemical processing, HDPE T-Rib liner sheets offer the protection and durability you need to extend the life of your structures and equipment.

Frequently Asked Questions (FAQs)

1. What is the lifespan of HDPE T-Rib liner sheets?

HDPE T-Rib liner sheets can last up to 50 years or more, depending on the application and environmental conditions. Their durability is one of the main reasons why they are so widely used.

2. Are HDPE T-Rib liner sheets environmentally friendly?

Yes, HDPE is a recyclable material, and using these liner sheets helps industries reduce their environmental impact by preventing contamination and leakage into the environment.

3. How thick are HDPE T-Rib liner sheets?

HDPE T-Rib liner sheets come in various thicknesses, typically ranging from 3 mm to 10 mm. The thickness required will depend on the specific application and the level of protection needed.

4. Can HDPE T-Rib liner sheets be used in high-temperature environments?

Yes, HDPE T-Rib liner sheets can withstand temperatures from -40°C to +80°C, making them suitable for a wide range of environmental conditions.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Juegos

- Gardening

- Health

- Inicio

- Literature

- Music

- Networking

- Otro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness