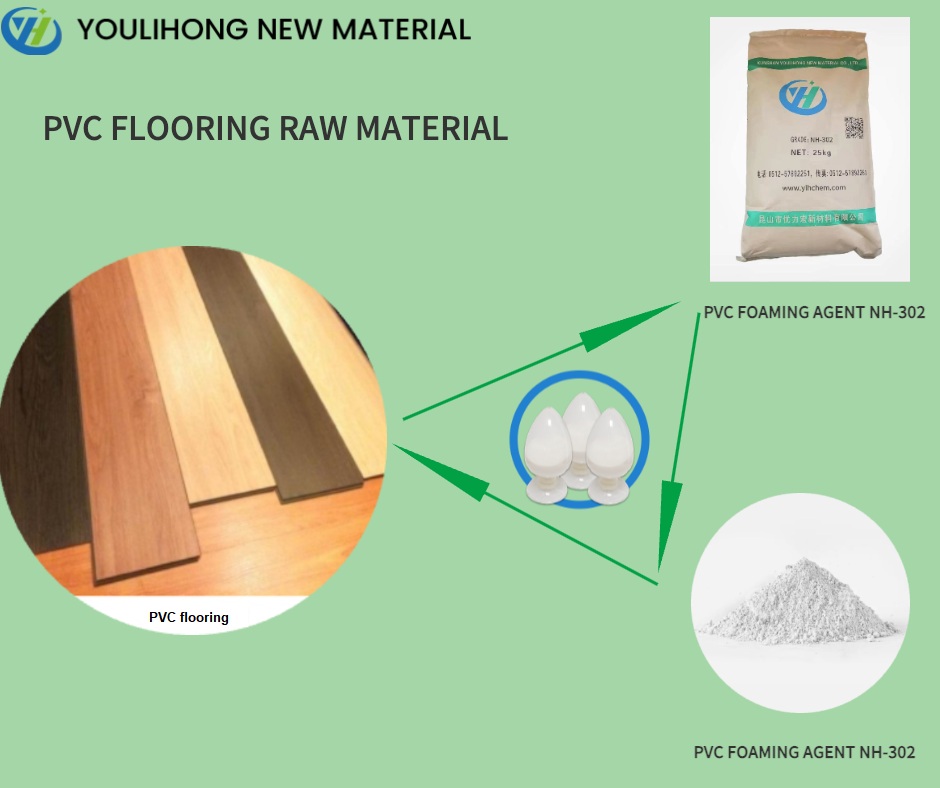

Choosing the Right Foaming Agent for Your PVC Flooring Applications

In the world of PVC flooring production, selecting the appropriate foaming agent is crucial for achieving optimal performance and quality. At Youlihong, we specialize in providing high-quality foaming agents designed specifically for PVC applications. Our foaming agents, such as CAS No. 10465-78-8, offer excellent properties that enhance the overall characteristics of PVC flooring. This guide will help you understand the factors to consider when choosing a foaming agent for your PVC flooring projects.

Understanding Foaming Agents

Foaming agents are additives used in the production of PVC flooring to create a cellular structure within the material. This structure not only improves the mechanical properties of the flooring but also contributes to its lightweight nature and thermal insulation capabilities. The right foaming agent can significantly impact the final product's durability, appearance, and performance.

Key Factors to Consider When Choosing a Foaming Agent

1. Type of Foaming Agent

There are two main categories of foaming agents: endothermic and exothermic. Endothermic foaming agents absorb heat during decomposition, leading to a controlled expansion process. In contrast, exothermic agents generate heat, causing rapid expansion. For PVC flooring, endothermic foaming agents are often preferred due to their stability and uniform bubble formation.

2. Purity and Composition

The purity of the foaming agent plays a significant role in determining its effectiveness. A higher purity level (such as 97% for our products) ensures consistent performance and reduces the risk of impurities affecting the final product's quality.

3. Decomposition Temperature

Different foaming agents have varying decomposition temperatures. It is essential to select a foaming agent that decomposes at a temperature compatible with your PVC processing conditions. For instance, our foaming agent starts decomposing at 110-130°C, making it suitable for various PVC applications.

4. Gas Yield

The gas yield indicates how much gas is produced during the decomposition of the foaming agent. A higher gas yield can lead to better foam density and structure. Our foaming agent offers a gas yield of 140-180 ml/g, ensuring effective expansion in PVC flooring.

5. Compatibility with Other Additives

Ensure that the chosen foaming agent is compatible with other additives used in your PVC formulation, such as stabilizers, plasticizers, and colorants. Compatibility is crucial for maintaining the desired physical properties and performance of the final product.

6. Environmental Considerations

With increasing emphasis on sustainability, it is essential to consider the environmental impact of your chosen foaming agent. Look for products that conform to environmental protection standards, minimizing harmful emissions during production.

Conclusion

Selecting the right foaming agent for your PVC flooring applications is vital for achieving high-quality results and optimal performance. At Youlihong, our integrated disposable subdermal needle electrodes provide advanced solutions tailored to meet your specific needs in PVC production. By considering factors such as type, purity, decomposition temperature, gas yield, compatibility, and environmental impact, you can make an informed decision that enhances your PVC flooring products. If you have any questions or need assistance with our foaming agents, feel free to reach out!

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Musica

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness