Laser Flange Machine for Precision Workpiece Marking Needs

Laser Flange Machine for Precision Workpiece Marking Needs

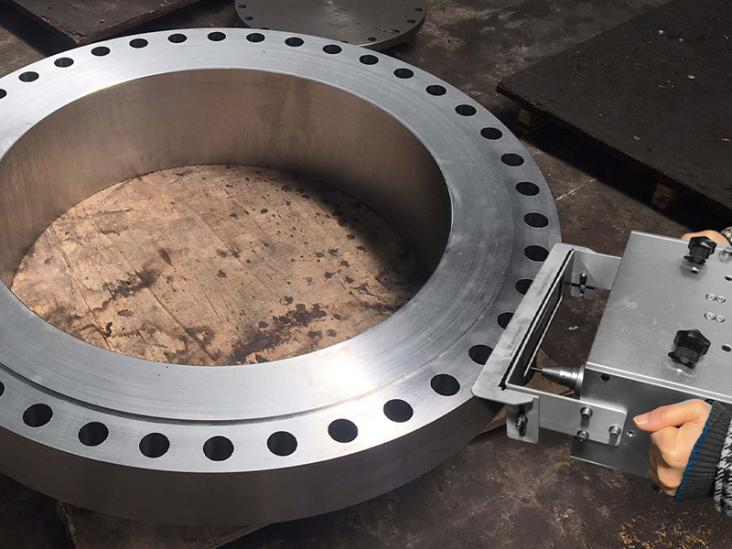

Laser flange marking utilizes a high-energy-density laser beam to locally irradiate the workpiece, causing the surface material to rapidly vaporize or undergo color changes, leaving a permanent mark. This marking method is non-contact and has no cutting force, which can effectively avoid workpiece damage that may be caused by traditional mechanical scribing or corrosion methods, ensuring the original precision and aesthetics of the workpiece.

In the marking process of precision workpieces, laser flange marking technology demonstrates its unique advantages. First, its fineness is extremely high, reaching the millimeter to micrometer level, and the marks produced are difficult to counterfeit and change, which is of great significance for anti-counterfeiting. Secondly, this technology has a wide range of applicability to materials. Whether it is metal, glass, ceramic or plastic, it can be marked, and the durability of the mark is very good.

In addition, laser flange marking also has the characteristics of high efficiency and environmental protection. Compared with traditional marking processes, laser marking can greatly improve production efficiency, and at the same time, it will not produce pollutants, which meets the environmental protection requirements of modern manufacturing.

In specific applications, laser flange marking machines are usually equipped with advanced computer numerical control systems, which can realize automatic processing, reduce manual intervention, and improve the accuracy and consistency of marking. At the same time, some high-end models also support a variety of marking modes, such as conical marking, which can meet the complex marking needs of different workpieces.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Musica

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness