Replaced Alloy Drill can maintain sharpness under extreme conditions

Selecting the right drilling tool is crucial for achieving precision and efficiency in any machining operation. A Replaceable Alloy Drill provides a flexible and durable solution for various drilling tasks, but choosing the appropriate type depends on specific work requirements.

The first factor to consider is the material being drilled. Different alloys and coatings are designed to handle specific materials, such as hardened steel, titanium, or composites. A replaceable alloy drill with a high heat-resistant coating is ideal for applications involving tough metals, as it can maintain sharpness under extreme conditions.

Another important aspect is drill size and geometry. Various designs are available to suit different hole depths and diameters. Whether working with shallow or deep holes, selecting the proper insert shape ensures efficient chip removal and precise cutting performance.

Furthermore, users should evaluate the attachment mechanism of the drill. A secure and easy-to-change insert system enhances efficiency by reducing the time spent on replacements. Some designs offer quick-locking features that simplify the exchange process, making them more convenient for operators.

By carefully assessing these factors, businesses can maximize the benefits of a replaceable alloy drill in their operations. Investing in the right tool setup ensures smoother production, reduced tool wear, and consistent drilling quality across different machining applications.

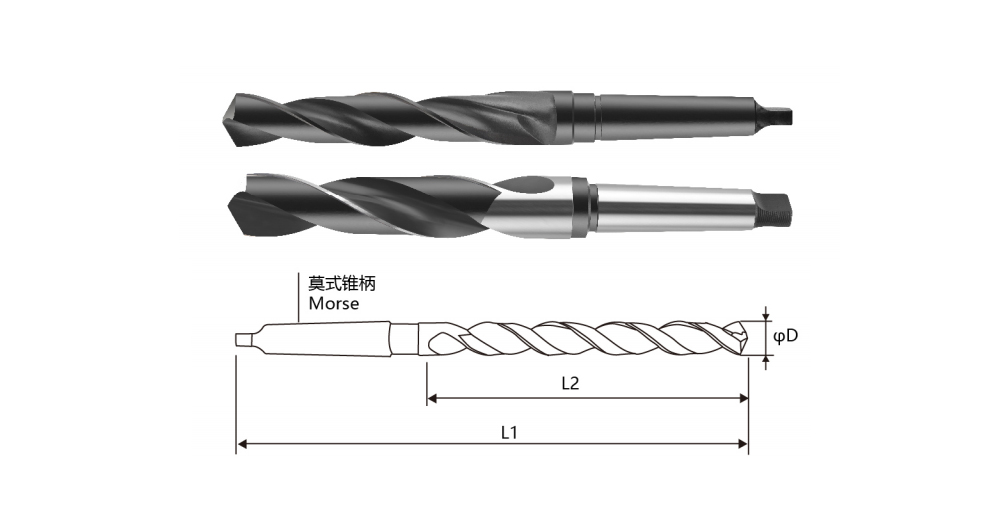

DIN345 4341/6542 tapered shank twist drill is a special drill for metal processing. It is usually made of high-quality 4341 or 6542 high-speed steel materials, which have good hardness and wear resistance, and are suitable for processing a variety of metal materials.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- الألعاب

- Gardening

- Health

- الرئيسية

- Literature

- Music

- Networking

- أخرى

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness