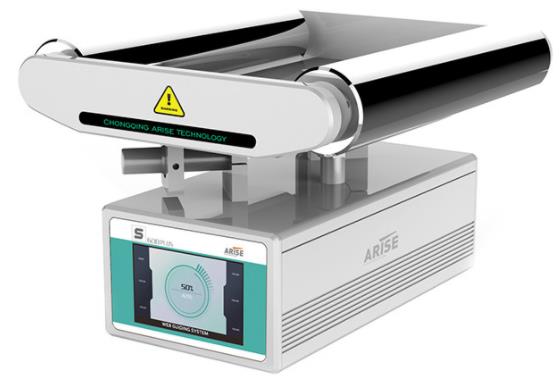

Web Guiding System - High-precision Edge Position Control

In the coil processing, due to the deviation of the coil itself or the machine, once the edge of the coil is not aligned, it will cause errors in subsequent processes, resulting in material waste or machine adjustment. In order to reduce the occurrence of such situations, the web guiding system can provide a solution for the edge position control of the coil.

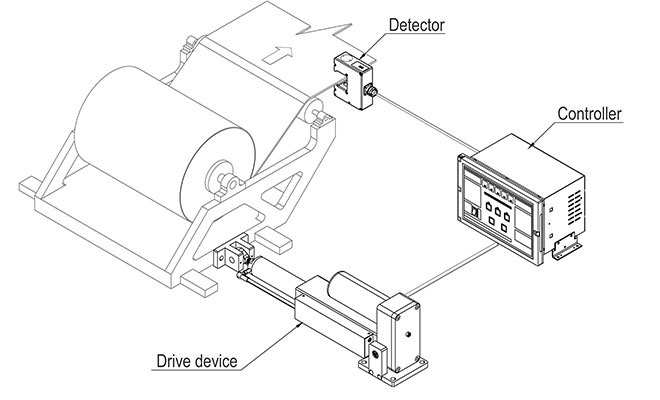

Web control refers to the technical operation that the coils must always be kept neat and consistent during the spraying, printing, punching, laminating, slitting, or other coil winding processes. When processing coils, it is necessary to perform edge guiding timely on the offset coils. This process is called web guiding. The equipment of the whole process constitutes a system. The web guiding system includes a controller, a web guide sensor, an electric drive, and a web guide mechanism.

The web guiding system is a closed-loop controller, which includes the controller, sensor, and web guide mechanism, as the basic complements of the system. First, the sensor detects the edge or of the coil, and the system automatically reads the offset of the actual position and the setting of the coil. Convert the offset into an electrical signal and send it to the controller. After the signal is amplified and calibrated by the controller, it is output to the driver. The linear driver drives the deviation correction mechanism according to the magnitude of the signal, to restore the coil to the set position. The drive signal of the current driver is only proportional to the deviation of the coil, which makes the web guiding system possible to provide precise control for various coils.

When the rolling speed of the material is relatively low, the speed of the motor should be low speed, otherwise, it will easily lead to over-correction. When the rolling speed is relatively high, then the speed of the motor should also be a high-speed correction. Adjust the winding speed of the correction motor through the frequency adjustment. The automatic web guiding can also be operated manually. It has the functions of automatic detection, automatic tracking, automatic correction, etc, which can track and correct the edges of paper, non-woven fabrics, film, aluminum foil, strip steel and other materials to ensure the roll winding and slitting neatly.

The web guiding system has a compact structure, good mechanical rigidity, low inertia, suitable for high-speed and high-precision edge position guiding in the middle of coil processing.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Musica

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness