What Is A Spring Made Of And What Is The Manufacturing Process Of A Spring

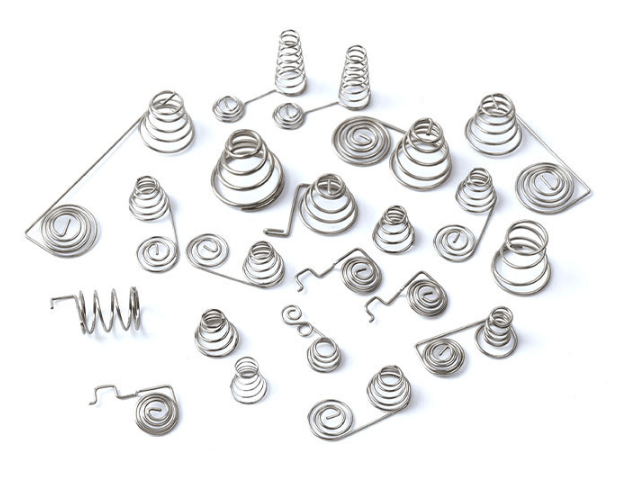

Compression springs, extension springs, torsion springs, volute springs, circlips, and other spring types are among the most prevalent. So, do you understand what the most common spring materials are and what are spring production process?

Metal spring materials that are commonly utilized

1. Spring steel, carbon spring steel: common grades include 70, 65Mn, T8, T9, and so on.

2. Alloy spring steel in grades such as 50CrV, 55CrSi, 60Si2Mn, and so on.

3. Stainless steel for springs, often used grades include 304, 316, 301, 201, 17-7PH, 12Cr18Ni9, 06Cr19Ni9, 07Cr17Ni7Al, and so on.

4. Copper alloys: Tin bronze, Silicon bronze, Beryllium-bronze, Brass/copper.

5. Nickel alloys: pure nickel, nickel-copper alloy, nickel-cobalt alloy, nickel-chromium alloy.

Non-metallic spring materials that are commonly utilized

1. Fluid material: gas (for example, a gas spring or a nitrogen spring), liquid (oil), or a gas-liquid mixture.

2. Ceramic materials are examples of inorganic materials. Rubber (rubber springs) and plastic fiber reinforced materials are examples of polymer materials.

Other special alloys include high-temperature alloy steel, Inconel, Hastelloy, high-speed tool steel, elastic element alloys, memory alloys, and so on.

What Kinds of Spring Coating Elements Exist?

Galvanized

Zinc is relatively stable in dry air, changes little, and is difficult to change color. In humid air, a white layer of zinc oxide or zinc carbonate forms. This dense film protects against additional rusting. Blue and white zinc, yellow zinc, colored zinc, and black zinc are common platings.

Plating with cadmium

Cadmium plating is commonly used to protect springs against corrosion, whereas cadmium plating is utilized to protect the inner metal. Because cadmium is an anode in comparison to iron, when it is pulled or cracked, the exposed iron metal beneath it can be protected by the cadmium plate's consumption. Cadmium is commonly found in atmospheric corrosion.

Copper plating

It is used in casting, nickel plating, chrome plating, silver plating, and gold plating.

Chrome plating

It is a silver-white metal with a microstrip blue finish. The chromium plating layer is extremely hard, with a hardness range of 400-1200HV depending on the plating solution composition and process parameters. The thermal characteristics of the chrome plating layer are excellent. Its gloss and hardness do not alter when heated below 500 °C. When the temperature exceeds 500 °C, it begins to oxidize and discolor. The hardness begins to decline at 700°C. The chromium plating layer has a low friction coefficient, particularly the dry friction coefficient, which is among the lowest of any metals. As a result, the chromium layer is abrasive.

Nickel plating

Nickel plating has a silvery white and yellowish look. Nickel plating is the electrolytic or chemical method of plating nickel on metals or nonmetals. Nickel plating is attractive and can be used to decorate. The cost is significant, and the procedure is quite difficult.

Tin plating

Tin plating has a silvery white look. It is a surface treatment process that uses tin plating on the surface of a metal, alloy, or other substance to add beauty and prevent rust.

Silver plating

The primary function of silver plating is to prevent corrosion while also increasing conductivity, reflectiveness, and attractiveness.

Galvanized titanium alloy

Galvanized titanium alloy is less expensive. It is corrosion resistant and stable, not easily rusted, and has a reasonably high hardness. It will be stronger than regular titanium alloys.

Spring zinc plating and cadmium plating play important roles

1. In humid air, a white layer of zinc oxide or zinc carbonate will form. This dense film protects against additional rusting. As a result, under typical atmospheric circumstances, the galvanized layer is used as a corrosion protection layer for springs. Springs in contact with solutions such as sulfuric acid, hydrochloric acid, and caustic soda, as well as springs working in humid air in an environment such as sulfur trioxide, should not be zinc-coated.

2. After plating, the galvanized layer is usually passivated. Passivation can improve the coating's protective function while also improving the surface's look.

3.The amount of protection is determined by the thickness of the zinc and cadmium coating. The thickness should normally be chosen based on the working environment during usage, and the thickness of the galvanized layer should be chosen between 6 and 24/m. The thickness of the cadmium plating layer should be chosen between 6 and 12/m.

KENENG has a big supply of different types of springs, such as compression springs, extension springs, torsion springs, die springs, battery springs, volute springs, disc springs, wire springs, flat spiral springs, etc, as well as bespoke springs, which can be designed and manufactured by our skilled spring design engineers based on your specific requirements or drawings.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- الألعاب

- Gardening

- Health

- الرئيسية

- Literature

- Music

- Networking

- أخرى

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness