Understanding the Influence of Cutting Speed on Horizontal Band Saw Machine Performance

In the realm of metalworking, the Horizontal Band Saw Machine stands as a pivotal piece of equipment used for cutting various materials, particularly metals. The efficiency and quality of the cut are heavily influenced by several factors, with cutting speed being one of the most critical. This article delves into the intricate relationship between the cutting speed of a Horizontal Band Saw Machine and the resulting quality of the material it processes.

The cutting speed of a Horizontal Band Saw Machine is defined as the rate at which the blade moves through the material. It is a crucial parameter that directly affects the quality of the cut, the tool life, and the overall productivity. A well-optimized cutting speed can lead to a clean, burr-free cut, while an inappropriate speed can result in poor material quality, increased tool wear, and even machine damage.

When the cutting speed of a Horizontal Band Saw Machine is too low, it can cause excessive heat generation due to the prolonged contact between the blade and the material. This heat can lead to material deformation, increased friction, and potential blade damage. On the other hand, if the cutting speed is too high, it might not allow sufficient time for the chips to clear from the cutting zone, leading to poor chip evacuation. This can cause the blade to overheat and dull quickly, affecting the surface finish and the dimensional accuracy of the cut.

Optimizing the cutting speed for a Horizontal Band Saw Machine involves a balance between achieving high productivity and maintaining the quality of the cut. A higher cutting speed can increase the throughput by reducing the time taken to cut a material, but it may also lead to a rough surface finish and increased tool wear. Conversely, a lower cutting speed might result in a better surface finish but at the cost of reduced productivity.

The material being cut also plays a significant role in determining the appropriate cutting speed for a Horizontal Band Saw Machine. Harder materials require a lower cutting speed to prevent blade breakage and to maintain a smooth cut. Conversely, softer materials can tolerate higher cutting speeds without compromising the quality of the cut.

Moreover, the tooth pitch of the blade used in a Horizontal Band Saw Machine is another factor that affects the cutting speed. A finer tooth pitch is suitable for cutting harder materials or for achieving a smoother finish, while a coarser tooth pitch is more appropriate for softer materials or faster cutting.

In addition to the material and blade characteristics, the condition of the Horizontal Band Saw Machine also influences the optimal cutting speed. A well-maintained machine with sharp blades, proper tension, and good alignment can operate at higher cutting speeds without compromising the quality of the cut.

In conclusion, the cutting speed of a Horizontal Band Saw Machine is a critical factor that directly affects the sawing quality of the material. It is essential to find the right balance between speed and quality to achieve the best results. This balance is influenced by the type of material being cut, the characteristics of the blade, and the condition of the machine itself. By understanding and adjusting the cutting speed accordingly, operators can optimize the performance of their Horizontal Band Saw Machine, ensuring high-quality cuts and extending the life of their cutting tools.

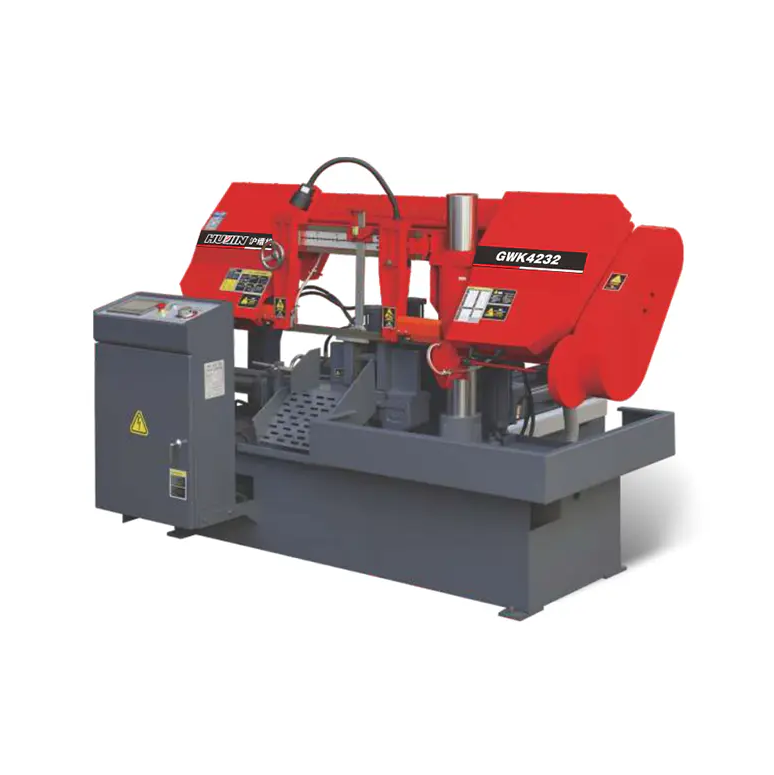

Cutting Capacity(mm) : Round material Φ500 Plate 500x500

Blade speed(m/min): 30,60,80

Blade Size(mm):1.3*41*6200

Single feeding travel(mm):500

Motor main output(kw): 4-6

Hydraulic(kw):1.5

Coolant pump(kw): 0.09

Machine Size(LxWxH)(mm): 3000*2200*1950

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness