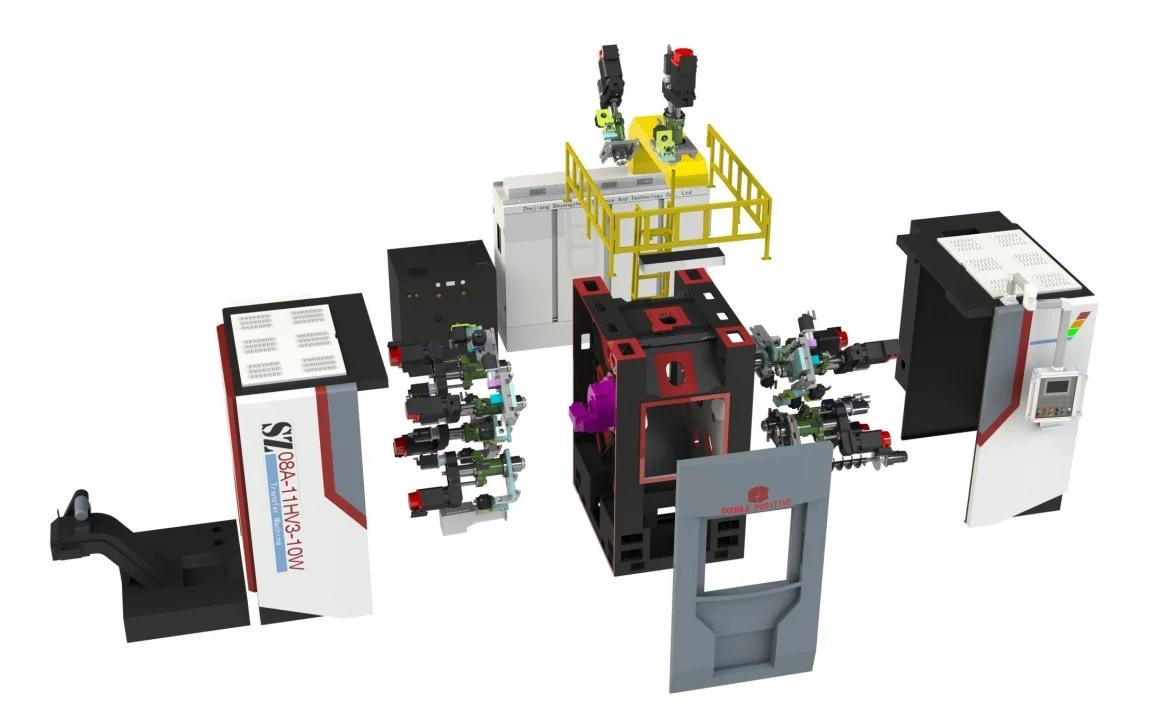

Servo Upside down Special Machine What are the causes of crawling in the feed system

Nowadays, the application of mechanical equipment is very frequent in major machinery industries. Servo Upside down Special Machine is an indispensable and very common mechanical equipment in the production and processing process of all machinery industries.

The use of CNC machine tools can effectively complete the processing of the workpiece, and its processing efficiency and processing accuracy are also very superior, which is the main reason why many enterprises choose it.

It is precisely because of the frequent use of CNC machine tools, it will easily lead to its failure. So what are the reasons for the "crawling" failure of the CNC machine tool feed system? The following Xiaobian will give you a detailed introduction.

In the process of driving the moving parts at low speed, the Servo Upside down Special Machine feed system will show that the moving parts cannot start at the beginning, but suddenly accelerate after starting, and then stop, and then accelerate again. The movement phenomenon of moving parts such as stopping and jumping, slow and fast is called crawling. And when it is running at high speed, the moving parts will appear obvious vibration.

The crawling of the machine feed system is generally considered to be due to poor lubrication between the moving parts of the machine tool, resulting in increased static friction resistance when the machine table moves; When the motor is driven, the table can not move forward, so that the ball screw produces elastic deformation, and the energy of the motor is stored on the deformation; When the motor continues to drive, and the elastic force produced by the stored energy is greater than the static friction force, the machine tool table wriggly forward, and the movement is repeated, resulting in the phenomenon of crawling.

In fact, this is only one of the reasons, the cause of this kind of failure may also be a failure of the mechanical feed transmission chain, it may also be a problem in the electrical part of the feed system, or the system parameter setting is improper, it may also be caused by the comprehensive failure of the mechanical part and the electrical part.

The above content has analyzed in detail the main reasons that will cause the Servo Upside down Special Machine feed system to produce "crawling" failure, and now everyone should understand it clearly! There are many reasons for this to happen in CNC machine tools.

Therefore, we should do a good job of maintenance of CNC machine tools in peacetime, so that we can effectively reduce the occurrence of failures in the use of CNC machine tools.

Servo Upside down Special Machine https://www.zjshuangzheng.com/Servo-Upside-down-Special-Machine-SZ10-151106HV3-14VV.html

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Oyunlar

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness