How Does Powder Coating Compare to Other Finishing Methods Like Anodizing Or Electroplating?

Powder coating, anodizing, and electroplating are all popular finishing methods for a variety of materials, but each has distinct advantages and disadvantages. Here's a comparison to help you decide which option is best for you:

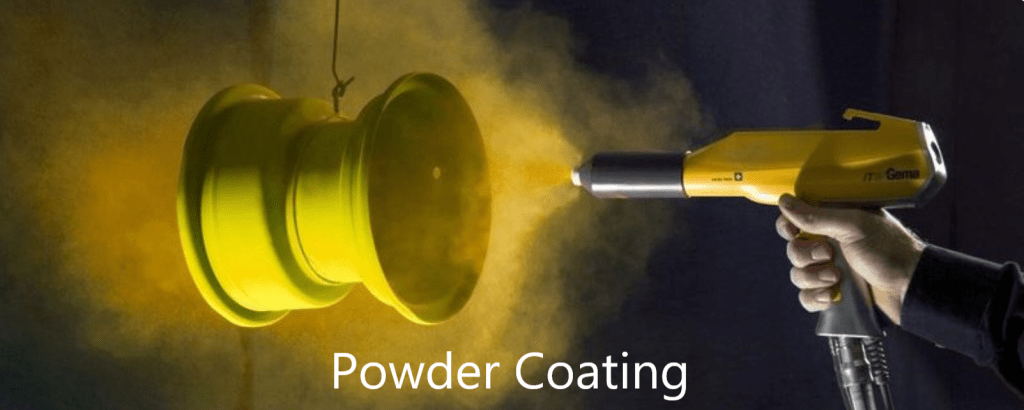

Powder Coating

Process: A dry powder is electrostatically applied to a surface and baked to cure.

Advantages:

Durable: Highly scratch, chip, and corrosion resistant.

Versatile: There are a wide range of colors and textures available.

Environmentally friendly: There were no volatile organic compounds or hazardous materials released during the process.

Cost-effective: Typically less expensive than anodizing or electroplating.

Disadvantages:

Thickness: Can be thicker than other finishes, which may not be suitable for all applications.

Heat sensitivity: Not recommended for heat-sensitive materials.

Limited conductivity: Not suitable for applications requiring electrical conductivity.

Anodizing

Process:An electrochemical process that forms a hard oxide layer on a metal's surface.

Advantages:

Durable: Extremely resistant to scratches, corrosion, and fading.

Lightweight: Does not add much weight to the material.

Good conductivity: Keeps the metal's electrical conductivity intact.

Aesthetic: Can create a wide range of metallic finishes and colors.

Disadvantages:

Limited material compatibility: Only works with certain metals, primarily aluminum.

Cost: It can be more expensive than powder coatings.

Thickness: Anodized layers are typically thinner than powder coatings.

Electroplating

Process: A metal coating is applied to the surface of another metal with an electric current.

Advantages:

Versatility: Can be applied to a wide variety of metals.

Conductivity: Maintains or increases the metal's electrical conductivity.

Corrosion resistance: Provides excellent corrosion resistance.

Disadvantages:

Environmental concerns: Electroplating can produce hazardous waste products.

Cost: Can be costly, particularly for complex finishes.

Adhesion: The bond between the coating and the base metal may be weaker than in other methods.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness