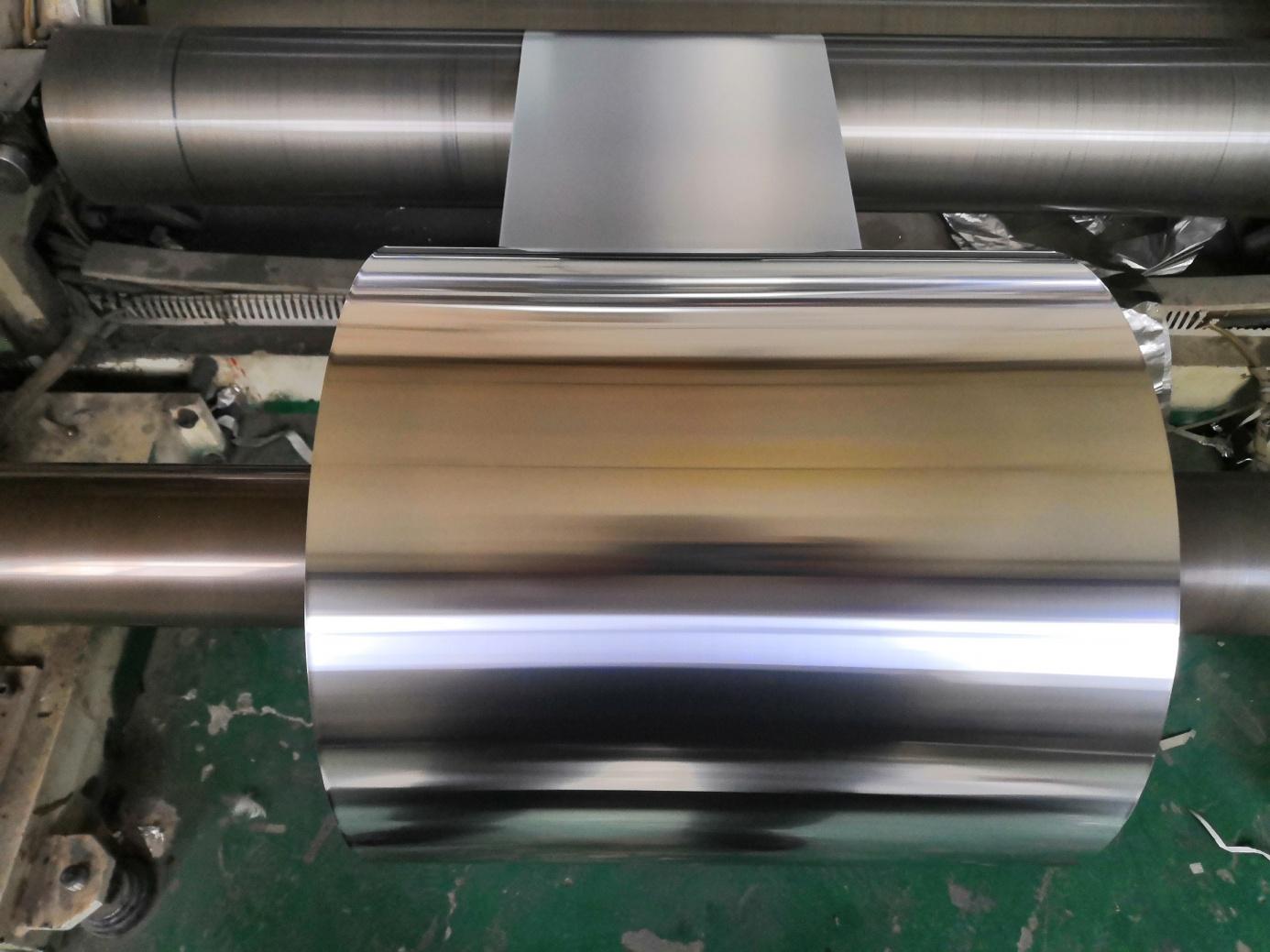

A way to print commercial aluminium foil

In addition to be used in household cooking, the industrial aluminium foil is extra often used in meals packaging, the primary level of which involves printing. Then a way to print it? And what are things really worth interest?

Surface cleaning

Whilst being positioned within the air, the commercial 8021 aluminium foil would right away reacts to the oxygen and a totally skinny layer of dense oxide could be shaped at the floor in no time. If the oxide layer isn't always dirty, the ink has properly adhesion. But, in real manufacturing, the aluminum foil paper is contaminated by lubricants and environmental dirt, and a completely thin movie layer is formed to affect the adhesion homes of the ink. Consequently, a floor cleaning procedure is inevitable earlier than printing aluminum foil. This is known as a pre-press etching coating treatment, aimed to remove the dust of the lubricant and enhance the adhesion among the ink and the foil surface. Also referred to as the lowest surface remedy, this is is to coat the floor of the aluminum foil paper with a shellac coating or a nitrocellulose coating. After coating, the printing surface is not an aluminium foil but a coating material. Those coating materials have accurate affinity with the ink, thereby improving the adhesion of the ink to the foil floor.

Pretreatment earlier than printing

Based on the information above, we will see that aluminum foil for packaging is virtually a composite material of aluminum and paint coating. In case of dramatic modifications of the temperature and humidity of the similarly processing environment, it's hard for the inner surroundings receives balanced with the outer surroundings, the double-layer shape connected through the internal coating or the adhesive will generate internal stress, in order to not most effective purpose form adjustments but additionally shape curls, wrinkles and waves because of the change of water content, which critically impacts the great of printing and submit-processing. Consequently, which will make sure the normal printing of aluminium foil for packaging, it is important to manipulate the temperature and humidity of the printing workshop, so that the temperature of the workshop is maintained at (25 + 2) ° C, and the relative humidity is maintained at 50% to 60%.

The temperature and humidity balance earlier than printing processing is essential. In any other case static power will be generated, so that you can make foil feeding hard. In real production, the authentic packaging of industrial aluminum foil have to be placed in the workshop for as a minimum 16 hours earlier than being opened for slicing, and some other eight-12 hours earlier than printing. Further, the published product must be protected with a plastic film to prevent moisture and reduce deformation at some point of processing.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness