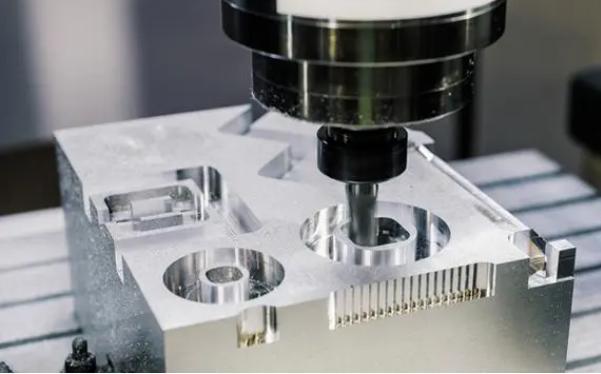

Can CNC Machining Create Complex Geometries in Plastic?

Yes, CNC machining can create complex geometries in plastic parts, offering a significant advantage for prototyping and low-volume production. However, its ability to handle complexity has limitations compared to machining softer metals like aluminum. Here's a breakdown of the capabilities and limitations to consider:

Strengths of CNC Machining for Complex Plastic Parts

l 3-Axis and Multi-Axis Machining: CNC machines come in various configurations, with 3-axis being the most common (X, Y, and Z movements). For complex shapes, multi-axis machines with additional rotary axes allow for machining from multiple directions, creating intricate features.

l Precise Tool Control: CNC machining offers exceptional control over cutting tool movement, enabling the creation of detailed features and curved surfaces on plastic parts.

l Wide Range of Plastics: A variety of plastics with different properties are suitable for CNC machining, allowing for selection based on strength, heat resistance, and desired finish for complex parts.

Limitations of Complexity Compared to Metals

l Material Properties: Plastics tend to be less rigid and have lower melting points compared to metals. This can limit the creation of very thin walls, sharp internal corners, or extremely small features due to potential deflection or melting during machining.

l Tooling Considerations: Cutting tools for plastic machining need to be sharp and designed to minimize heat generation. This can limit tool selection compared to machining metals, potentially impacting achievable complexity.

l Machining Speeds and Feed Rates: To avoid melting or deforming the plastic, machining speeds and feed rates need to be carefully controlled, which can be slower than machining metals, impacting the ability to handle highly intricate geometries.

Designing for Complexity in CNC Machined Plastics

l Smoother Transitions: Sharp internal corners or sudden changes in geometry can be challenging. Gradual transitions and chamfers are recommended for better machinability.

l Minimum Wall Thickness: Understanding the minimum achievable wall thickness for your chosen plastic is crucial. Consulting your CNC machining service provider can help establish this limit for your design.

l Draft Angles: Adding slight draft angles to features like sidewalls helps with tool clearance and reduces the risk of scraping during machining, especially for deeper cuts on complex shapes.

When Complexity Might Exceed CNC Machining's Limits

l Extremely Thin Walls or Microscopic Features: If your design requires features with wall thicknesses approaching the limitations of the chosen plastic or features with micron-sized details, alternative methods like 3D printing might be better suited.

l Extensive Undercuts or Enclosed Cavities: CNC machining typically struggles with features that require the tool to access recessed areas. Consider design alternatives or post-processing techniques if such features are necessary.

Conclusion

CNC machining is a powerful tool for creating complex geometries in plastic parts, offering a balance of precision and design flexibility. However, understanding the limitations compared to machining metals and designing with those limitations in mind is crucial for successful production. For extreme complexity exceeding CNC machining's capabilities, alternative manufacturing methods might be a better fit. Consulting with a qualified CNC machining service provider early in the design phase can help ensure your complex plastic parts are achievable and meet your functional and aesthetic requirements.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Startseite

- Literature

- Musik

- Networking

- Andere

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness