A Closer Look at NVMe SSD Manufacturers' Data Preservation Techniques

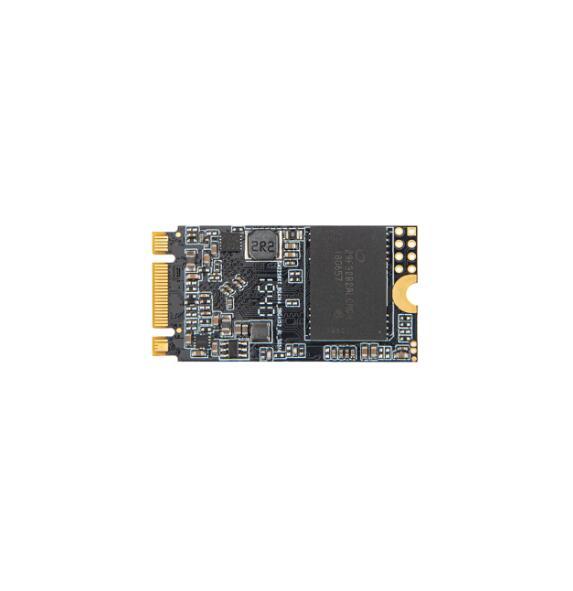

The advent of NVMe SSD technology has brought about a significant leap in the performance and reliability of data storage devices. As the market leaders in this domain, NVMe SSD manufacturers are constantly pushing the boundaries of what is possible in terms of speed, capacity, and durability. One of the key performance indicators that these manufacturers must address is the data retention capability of their products, especially when it comes to long-term storage. This article delves into the various strategies and technologies employed by NVMe SSD manufacturers to ensure that their products maintain data integrity over extended periods.

Data retention is a critical factor for any storage device, as it directly impacts the reliability and trustworthiness of the system. For NVMe SSD manufacturers, this means ensuring that the data stored on their devices remains accessible and accurate, even after months or years of inactivity. The challenge is compounded by the fact that SSDs, unlike traditional hard disk drives (HDDs), use NAND flash memory, which has its own set of limitations and degradation mechanisms.

To combat these issues, NVMe SSD manufacturers employ a variety of techniques to enhance the data retention capabilities of their products. One such approach is the use of advanced error correction codes (ECC) and wear leveling algorithms. ECC helps to detect and correct data corruption that may occur due to various factors, such as power fluctuations or physical damage to the memory cells. Wear leveling, on the other hand, ensures that the write cycles are distributed evenly across the memory cells, preventing any single cell from wearing out prematurely.

Another important consideration for NVMe SSD manufacturers is the quality of the NAND flash memory used in their products. Different types of NAND flash, such as SLC, MLC, TLC, and QLC, have varying levels of endurance and data retention capabilities. Manufacturers must carefully select the appropriate type of NAND flash for their target market, balancing the need for cost-effectiveness with the required performance and reliability.

Temperature management is another area where NVMe SSD manufacturers must demonstrate innovation. High temperatures can accelerate the degradation of NAND flash memory, leading to a reduction in data retention times. To mitigate this, manufacturers often incorporate thermal sensors and cooling solutions into their SSD designs, ensuring that the devices operate within optimal temperature ranges.

In addition to hardware-based solutions, NVMe SSD manufacturers also invest in firmware and software optimizations to enhance data retention. Firmware updates can introduce new algorithms and features that improve the overall performance and reliability of the SSD, while software tools can help users monitor the health of their storage devices and take proactive measures to maintain data integrity.

The testing and validation processes employed by NVMe SSD manufacturers are also crucial in ensuring long-term data retention. Rigorous testing protocols, including stress tests and endurance tests, are conducted to simulate the various conditions that the SSDs may encounter in real-world applications. These tests help manufacturers identify potential issues and make necessary improvements to their products before they reach the market.

In conclusion, the data retention capabilities of NVMe SSD manufacturers' products are a complex interplay of hardware design, firmware optimization, and quality control measures. As the demand for reliable and long-lasting storage solutions continues to grow, manufacturers must remain at the forefront of innovation, constantly refining their products to meet the evolving needs of their customers. By doing so, they can ensure that their NVMe SSDs remain a trusted and indispensable component of modern data storage infrastructures.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness