Innovative HDPE Duct Couplers: Revolutionizing Pipeline Connectivity

The infrastructure and construction industries in India are rapidly evolving, driven by the growing demand for efficient water management, telecommunications, and gas distribution systems. A key component that is becoming increasingly critical in these sectors is the HDPE duct coupler India, an essential solution that ensures the seamless joining of high-density polyethylene (HDPE) pipes. The advantages of these couplers lie in their durability, flexibility, and cost-effectiveness. As the country expands its pipeline infrastructure, the role of HDPE pipe coupling suppliers in providing high-quality solutions is paramount. In this article, we will explore the importance of HDPE duct couplers, the role of high-density polyethylene coupler systems, and the benefits they offer across various industries.

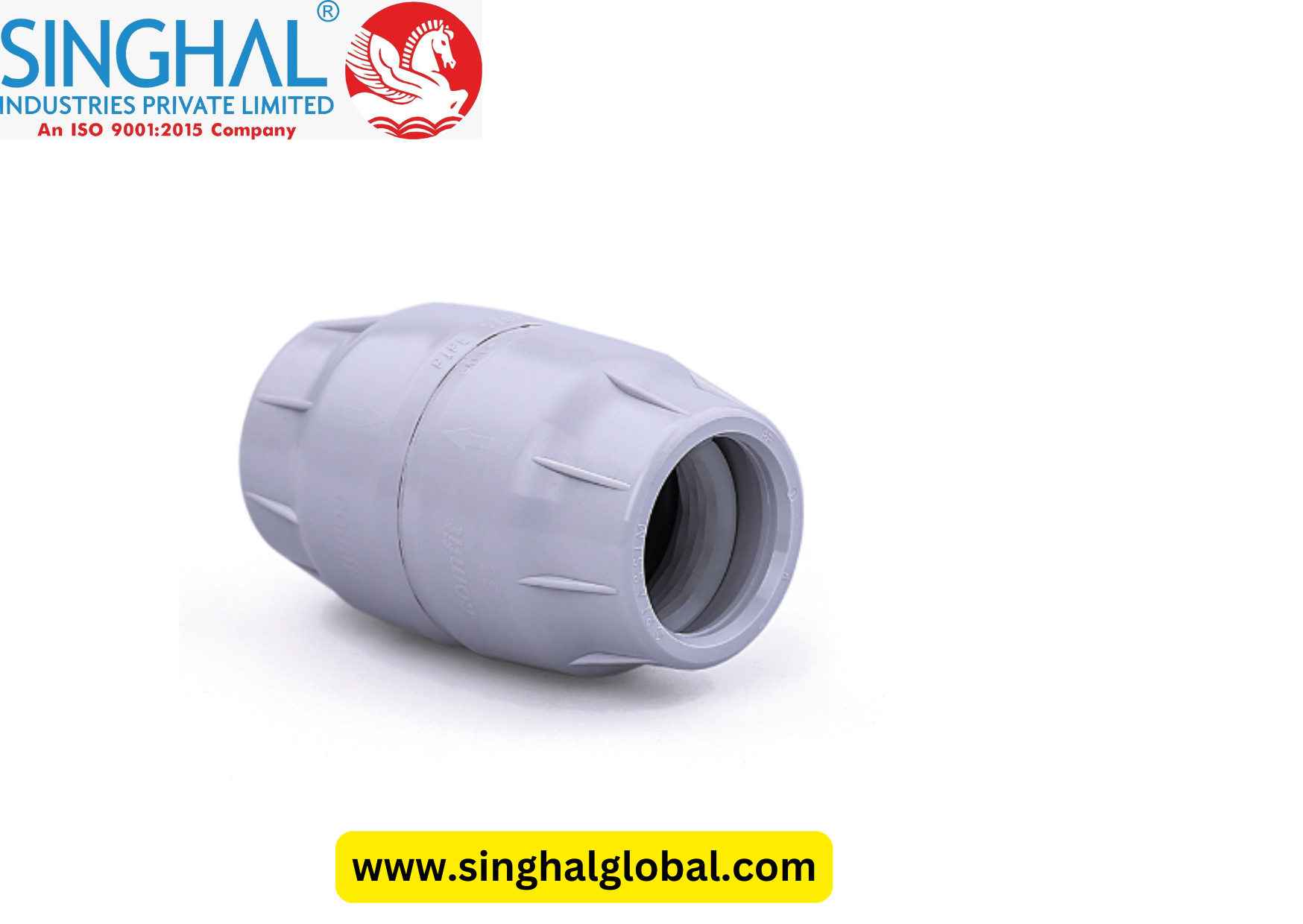

What Is an HDPE Duct Coupler?

An HDPE duct coupler is a device used to connect two sections of HDPE pipes or ducts securely. These couplers ensure that the pipes or ducts remain aligned and sealed, preventing leakage or disconnection during operation. HDPE duct couplers are commonly used in industries such as telecommunications, gas distribution, water supply, and even electrical conduits. The high demand for such couplers in India arises from the country's rapid urbanization and infrastructure development.

The primary advantages of HDPE duct couplers include:

- Durability: HDPE duct couplers are resistant to corrosion, chemical reactions, and weather conditions, making them ideal for long-term use in harsh environments.

- Flexibility: These couplers allow for slight movement and flexibility in the piping system, which is important in areas prone to ground shifts or temperature fluctuations.

- Easy Installation: HDPE duct couplers are designed for quick and easy installation, reducing the time and labor costs involved in large-scale projects.

The Role of HDPE Duct Coupler in India

India is currently experiencing an infrastructure boom, with extensive development projects in transportation, water management, telecommunications, and energy sectors. The need for reliable and durable pipeline solutions has driven the widespread adoption of HDPE pipes and couplers. HDPE duct coupler India is pivotal in ensuring that pipelines used in these industries are joined securely, without compromising the system’s integrity.

-

Water Supply Systems: India’s water management systems are undergoing significant upgrades to meet the needs of a growing population. HDPE pipes are favored for their resistance to corrosion and ability to transport water over long distances without contamination. HDPE duct coupler India provides a secure connection between these pipes, ensuring that water is delivered efficiently to both urban and rural areas.

-

Telecommunications: In the era of digital communication, reliable infrastructure for data transmission is crucial. HDPE duct couplers are widely used in laying optical fiber cables, which are housed within HDPE ducts. These couplers ensure that the cables are securely housed, allowing for uninterrupted data transmission.

-

Gas Distribution: The demand for natural gas as a cleaner source of energy has increased significantly in India. HDPE pipes and high-density polyethylene coupler systems provide a safe and leak-proof method for transporting gas across vast distances. These couplers ensure that gas pipelines are securely connected, minimizing the risk of leaks.

-

Electrical Conduits: HDPE duct couplers are also used in electrical conduit systems, protecting electrical cables from external damage and ensuring that they remain secure during installation and operation.

Benefits of High-Density Polyethylene Couplers

High-density polyethylene coupler systems offer numerous benefits, which make them an ideal choice for various applications in India’s growing infrastructure projects. Some of the key advantages include:

-

Chemical Resistance: HDPE couplers are highly resistant to chemicals, making them suitable for use in environments where pipes may come into contact with corrosive substances.

-

Longevity: Due to their durability and resistance to wear and tear, HDPE couplers have a long lifespan. This reduces the need for frequent repairs or replacements, ultimately lowering maintenance costs.

-

Leak-Proof Sealing: One of the most critical features of HDPE duct couplers is their ability to provide a leak-proof seal. This ensures the safe transportation of liquids and gases, making them essential in industries where leakage can be hazardous or costly.

-

Environmental Friendliness: HDPE is a recyclable material, and the use of HDPE couplers contributes to environmentally sustainable construction practices. Additionally, the longevity and reliability of HDPE duct couplers reduce waste and resource consumption over time.

-

Cost-Effective: HDPE duct couplers are cost-effective compared to other materials like steel or copper. They offer excellent performance at a lower price point, making them ideal for large-scale infrastructure projects.

-

Easy to Transport and Install: The lightweight nature of HDPE duct couplers makes them easier to transport and install than traditional metal couplers. This reduces labor costs and accelerates project timelines, which is critical in fast-paced construction environments.

HDPE Pipe Coupling Suppliers: Key Players in the Market

The role of HDPE pipe coupling suppliers is crucial in ensuring that high-quality products are available for infrastructure projects across India. These suppliers act as a vital link between manufacturers and end-users, providing the necessary materials for building pipelines, ducts, and conduits. Key responsibilities of suppliers include:

-

Quality Assurance: Suppliers work closely with manufacturers to ensure that the HDPE couplers meet industry standards for durability, strength, and performance. They provide certification and testing data to reassure clients that the products are reliable.

-

Technical Support: HDPE pipe coupling suppliers often offer technical support to construction companies and engineers. This ensures that the correct type and size of couplers are chosen for specific projects and that they are installed correctly.

-

Wide Distribution Network: A well-established network of suppliers ensures that even remote areas of India have access to high-quality HDPE duct couplers. This is particularly important for rural development projects and expanding infrastructure into less developed regions.

-

Competitive Pricing: Suppliers provide competitive pricing for bulk orders, allowing large-scale projects to procure materials without exceeding their budgets. This is essential in industries where cost efficiency is critical.

Future of HDPE Duct Couplers in India

As India continues to invest in its infrastructure, the demand for HDPE duct couplers will only increase. Innovations in material science are likely to further improve the performance and longevity of HDPE products, making them even more appealing for use in pipelines, ducts, and conduits. Additionally, the focus on sustainable construction practices will continue to drive demand for recyclable and environmentally friendly materials like HDPE.

Conclusion

HDPE duct couplers have become a vital component of India’s growing infrastructure. Whether in water management, telecommunications, gas distribution, or electrical conduit systems, high-density polyethylene coupler solutions provide durability, reliability, and cost-effectiveness. With the support of HDPE pipe coupling suppliers, the use of these couplers is expanding across various sectors, playing a key role in India's development journey.

Here Are Three Related For HDPE duct coupler India

Q1: How long do HDPE duct couplers typically last?

Ans. HDPE duct couplers are highly durable and can last for several decades, depending on environmental factors and the specific application.

Q2: What are the primary industries that use HDPE duct couplers?

Ans. HDPE duct couplers are commonly used in telecommunications, water supply, gas distribution, and electrical conduit systems.

Q3: Are HDPE duct couplers environmentally friendly?

Ans. Yes, HDPE duct couplers are made from recyclable materials and contribute to sustainable construction practices by reducing waste and minimizing environmental impact.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Oyunlar

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness