Polycarbonate (PC) hollow sheets are increasingly becoming a go-to material in various industries due to their unique combination of durability, transparency, and flexibility. These lightweight yet robust sheets provide excellent thermal insulation, high impact resistance, and weather endurance, making them highly suitable for construction, agriculture, and industrial applications.

In this article, we Pulkit Plastic Products explore everything you need to know about PC hollow sheets, including their features, types, and common uses, along with answering frequently asked questions.

What Are PC Hollow Sheets?

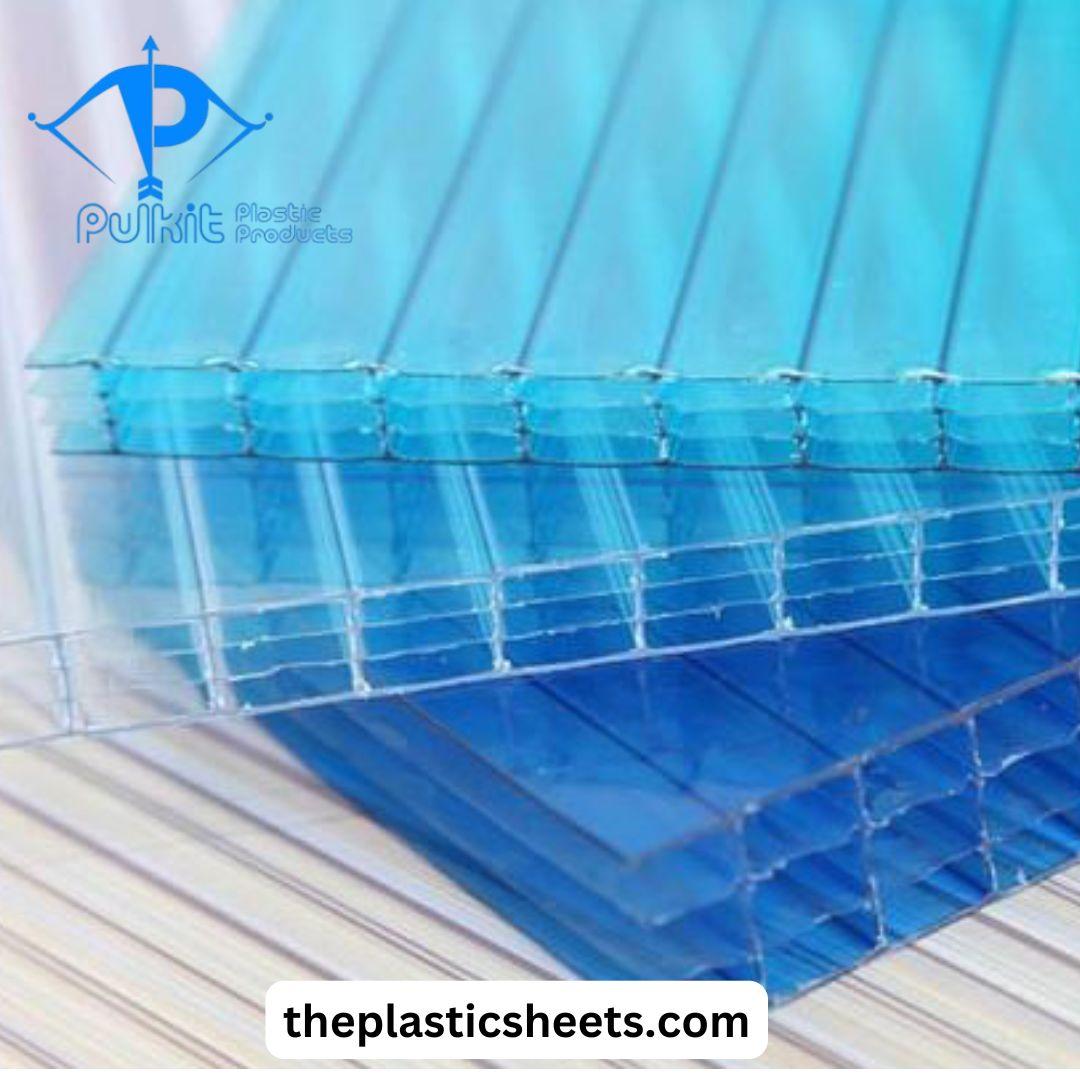

PC hollow sheets are polycarbonate-based plastic materials that consist of multiple layers, with hollow air pockets in between. The term "hollow" refers to the internal structure, which includes chambers that trap air, resulting in excellent thermal insulation while reducing the overall weight of the sheets. This unique structure gives Hollow Polycarbonate Sheet their characteristic strength, lightness, and transparency.

Compared to solid polycarbonate sheets, the hollow design provides additional benefits, such as better insulation and easier handling. These sheets are available in various thicknesses, sizes, colors, and surface textures, depending on the application.

Key Features of PC Hollow Sheets:

-

Lightweight and Strong: The hollow structure reduces the sheet’s weight without compromising strength, making it easy to transport and install.

-

Thermal Insulation: The internal air chambers provide superior insulation, making PC hollow sheets ideal for roofing and glazing in energy-efficient buildings.

-

High Impact Resistance: PC hollow sheets are nearly 200 times stronger than glass and can withstand strong impacts, making them an excellent choice for areas prone to extreme weather or vandalism.

-

UV Protection: Many PC hollow sheets come with UV-resistant coatings that prevent degradation from prolonged exposure to sunlight, ensuring long-term clarity and performance.

-

Transparency: PC hollow sheets offer high levels of light transmission, allowing natural light to pass through while still providing insulation.

-

Weather Resistance: These sheets are highly resistant to temperature extremes, humidity, and outdoor elements, making them suitable for diverse environments.

-

Fire Resistance: PC hollow sheets have inherent flame-retardant properties, making them a safer choice for construction projects.

Types of PC Hollow Sheets

There are various types of PC hollow sheets, each designed for specific applications and offering unique advantages:

1. Twin-Wall Hollow Sheets:

These are the most common type of PC hollow sheets, featuring two parallel walls with a single air chamber in between. Twin-wall sheets provide excellent thermal insulation and light diffusion, making them ideal for greenhouses, roofing, and partitions.

2. Triple-Wall Hollow Sheets:

With an additional layer, triple-wall hollow sheets offer even better insulation and strength. They are commonly used in energy-efficient buildings, where superior insulation and structural support are required.

3. Four-Wall Hollow Sheets:

These sheets are designed for more demanding applications, offering the highest level of insulation and impact resistance. Four-wall hollow sheets are commonly used in industrial buildings, sports arenas, and large commercial facilities.

4. Corrugated Hollow Sheets:

Corrugated hollow sheets have a wavy design that enhances their rigidity and load-bearing capacity. They are commonly used in agricultural applications, such as greenhouses, where additional strength and flexibility are required.

Applications of PC Hollow Sheets

The Polycarbonate Hollow Sheet are used in a wide range of industries and applications due to their versatility, durability, and performance. Below are some of the key areas where these sheets are most commonly utilized:

1. Construction and Architecture:

In the construction industry, PC hollow sheets are used in several ways, from roofing and skylights to facades and partitions. Their lightweight nature makes them easy to work with, while their transparency allows for ample natural lighting, reducing energy costs.

-

Skylights and Roofing: PC hollow sheets are ideal for roofing applications due to their excellent light transmission and thermal insulation properties. They are used in residential, commercial, and industrial buildings where natural light is needed without sacrificing insulation or safety.

-

Facades and Cladding: Architects use PC hollow sheets to create modern, transparent building facades. The sheets provide an elegant, glass-like appearance but are much more durable and resistant to impact and weathering.

2. Greenhouses and Agriculture:

PC hollow sheets are a popular choice in agricultural settings, particularly for greenhouse roofing. Their high light transmission promotes plant growth, while their thermal insulation helps regulate temperature, reducing heating and cooling costs.

-

Greenhouse Roofing: The transparency and insulation provided by PC hollow sheets make them perfect for greenhouse roofs, ensuring that plants receive sufficient sunlight while maintaining an optimal indoor climate.

-

Animal Shelters: In agricultural settings, these sheets are also used to construct animal shelters, barns, and other structures where durability, insulation, and natural light are needed.

3. Industrial Applications:

In industrial environments, PC hollow sheets are used for various protective and structural purposes. They are strong enough to withstand high-impact areas and can be used in the construction of protective barriers, machine guards, and partitions.

-

Machine Guards: Due to their impact resistance, PC hollow sheets are often used to create protective guards around industrial machinery. They provide visibility while ensuring safety.

-

Warehouse Roofing: Industrial facilities use PC hollow sheets for warehouse roofs to maximize natural light and reduce energy consumption.

4. Signage and Advertising:

The transparency, durability, and flexibility of PC hollow sheets make them ideal for signage and advertising displays. They are lightweight, easy to cut into various shapes, and can withstand outdoor conditions, making them suitable for both indoor and outdoor signs.

-

Billboards and Advertising Signs: These sheets are commonly used for large outdoor signs, where weather resistance and impact durability are crucial.

-

Exhibition Displays: PC hollow sheets are also used in trade show and exhibition displays due to their lightweight and attractive appearance.

5. Transportation and Automotive:

In the automotive and transportation industry, PC hollow sheets are used to create lightweight, impact-resistant components. They are also used in bus shelters, railway stations, and walkways due to their transparency and durability.

-

Bus Stops and Shelters: PC hollow sheets are used to construct transparent yet durable shelters for public transportation stops, providing protection from the elements without blocking light.

-

Vehicle Components: Certain vehicle parts, like sunroofs or protective shields, can be made from PC hollow sheets due to their impact resistance and light weight.

Benefits of Using PC Hollow Sheets

PC hollow sheets offer numerous benefits, making them a highly preferred material across various industries. Here are the key advantages:

1. Energy Efficiency:

Due to their excellent thermal insulation properties, PC hollow sheets help reduce energy costs by regulating indoor temperatures, particularly in greenhouses, skylights, and roofing applications.

2. Durability and Impact Resistance:

The durability and impact resistance of PC hollow sheets make them ideal for applications where safety and long-term performance are priorities. Their ability to withstand strong forces ensures they can endure harsh weather and heavy use without damage.

3. Light Transmission:

PC hollow sheets offer excellent light transmission, reducing the need for artificial lighting in many applications. This not only creates brighter, more inviting spaces but also reduces energy consumption.

4. Design Flexibility:

These sheets are easy to cut, bend, and mold, making them adaptable to various design requirements. Whether for architectural facades or custom signage, PC hollow sheets can be shaped to fit specific needs.

5. Weather and UV Resistance:

PC hollow sheets are resistant to extreme weather conditions, including heavy rain, snow, and UV radiation. Their UV-protective coating prevents yellowing and degradation, ensuring longevity even in harsh outdoor environments.

Conclusion

The Hollow Sheet Polycarbonate are a versatile, durable, and energy-efficient material that has wide-ranging applications across industries like construction, agriculture, and signage. Their lightweight design, coupled with superior impact resistance and thermal insulation, makes them ideal for projects requiring durability and transparency.

Whether you’re constructing a greenhouse, designing a modern architectural facade, or building a skylight, PC hollow sheets offer a flexible, long-lasting solution that meets the demands of both functionality and aesthetics.

Frequently Asked Questions (FAQs)

Q1: How do PC hollow sheets compare to glass?

PC hollow sheets are significantly stronger and more impact-resistant than glass, while also being much lighter. Additionally, they provide better thermal insulation and are less prone to breaking, making them a safer and more durable alternative for many applications.

Q2: Are PC hollow sheets UV resistant?

Yes, most PC hollow sheets are treated with a UV-resistant coating that prevents them from degrading or yellowing when exposed to sunlight. This makes them ideal for outdoor use in skylights, roofing, and greenhouses.

Q3: Can PC hollow sheets be recycled?

Yes, PC hollow sheets are recyclable. Polycarbonate is a thermoplastic material, meaning it can be melted down and reprocessed into new plastic products. This makes PC hollow sheets an environmentally friendly option.

Q4: What is the typical lifespan of PC hollow sheets?

With proper care and installation, PC hollow sheets can last anywhere from 10 to 20 years or longer. Their longevity depends on factors such as the environment, UV exposure, and how they are maintained.