HDPE T-Rib Liner Sheets: The Ultimate Solution for Corrosion and Waterproofing

In industries such as construction, wastewater management, and tunnel lining, protecting structures from corrosion and wear is crucial. One of the most reliable solutions is the use of HDPE T-Rib Liner Sheets. These sheets are designed to provide superior protection against chemical exposure, moisture, and other damaging factors that can degrade materials over time. In this article, we will explore what Mahira Polyglobal LLP are, their advantages, common applications, and answer frequently asked questions to provide a complete understanding of this innovative material.

What Are HDPE T-Rib Liner Sheets?

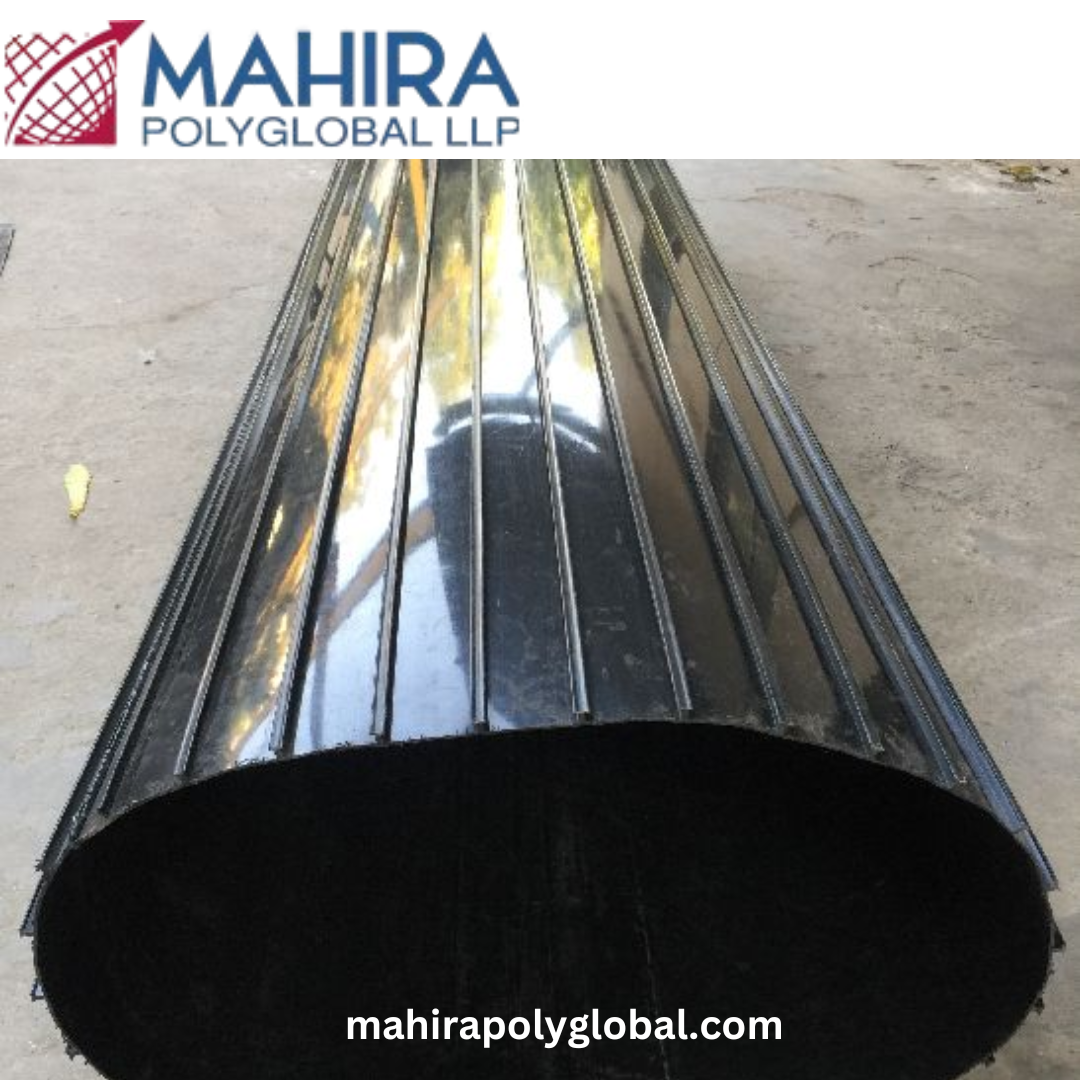

HDPE T Rib Liner are a type of plastic sheeting specifically designed for lining and protecting concrete and metal structures. HDPE is a thermoplastic made from petroleum, known for its strength, durability, and resistance to various chemicals and environmental factors. The "T-Rib" design refers to the unique T-shaped ribs on the underside of the liner sheet, which provide better anchorage when embedded in concrete or other surfaces. This feature ensures that the liner remains securely in place, even in harsh conditions.

The purpose of these liner sheets is to create a protective barrier that prevents the infiltration of water, chemicals, and other corrosive substances into the structures. HDPE T-Rib liner sheets are particularly popular in industries where corrosion is a major issue, such as in sewage systems, tunnels, mining operations, and chemical plants.

Key Features of HDPE T-Rib Liner Sheets

-

High Chemical Resistance: One of the standout features of HDPE T-Rib liner sheets is their ability to resist corrosion caused by a wide range of chemicals, including acids, alkalis, and solvents.

-

Durability: HDPE material is extremely tough and long-lasting, capable of withstanding harsh environmental conditions and heavy loads. It is highly resistant to cracking, punctures, and wear.

-

Waterproofing Capabilities: These liner sheets are impermeable to water and moisture, making them ideal for use in tunnels, basements, and sewage systems where water infiltration is a concern.

-

Thermal Stability: HDPE T-Rib liner sheets can endure significant temperature variations, from freezing to high heat, without losing their properties.

-

Lightweight and Flexible: Despite their strength, HDPE T-Rib liner sheets are lightweight and flexible, making them easier to transport and install compared to other materials like metal or concrete.

-

UV Resistance: For outdoor applications, HDPE offers strong resistance to UV radiation, meaning it can be exposed to sunlight for extended periods without degrading.

Applications of HDPE T-Rib Liner Sheets

The T-Rib HDPE liner sheets India have a wide range of industrial applications, thanks to their superior resistance to chemicals, water, and environmental stress. Here are some common uses:

-

Sewage Treatment Plants:

- Sewage systems are exposed to a variety of corrosive chemicals and biological waste, making HDPE T-Rib liner sheets an ideal solution for lining tanks, pipes, and concrete structures to prevent corrosion and leakage.

-

Tunnel Lining:

- In tunnel construction, water infiltration can weaken the structure over time. HDPE T-Rib liner sheets provide excellent waterproofing and durability, protecting tunnels from moisture and other environmental factors.

-

Mining Industry:

- The mining industry deals with highly corrosive materials, chemicals, and challenging environments. HDPE T-Rib liner sheets are used to line mine shafts, pits, and storage areas to prevent damage from acidic or toxic substances.

-

Chemical Storage Tanks:

- HDPE T-Rib liners are used in chemical storage tanks to protect against the harmful effects of chemical exposure. The chemical resistance of HDPE ensures that tanks remain intact even when storing highly corrosive substances.

-

Waterproofing Basements and Foundations:

- In construction, HDPE T-Rib liner sheets are used to waterproof basements, foundations, and retaining walls, preventing water ingress that can cause structural damage and mold growth.

-

Wastewater Treatment:

- HDPE T-Rib liner sheets play a vital role in wastewater treatment plants, helping to line tanks, channels, and pipes that come into contact with harmful chemicals and sewage.

-

Landfill Liners:

- HDPE liner sheets are widely used in landfill construction to create a protective barrier between waste and the surrounding environment, preventing the leaching of harmful substances into groundwater.

Advantages of HDPE T-Rib Liner Sheets

-

Longevity and Low Maintenance

- HDPE T-Rib liner sheets are designed for long-term performance, with a lifespan of several decades when properly installed. The durable material requires minimal maintenance, making it a cost-effective solution over time.

-

Corrosion and Chemical Resistance

- The most significant advantage of HDPE T-Rib liners is their resistance to a broad range of chemicals, making them ideal for use in environments exposed to harsh substances like sewage, industrial chemicals, and salts.

-

Easy Installation

- The lightweight nature of HDPE T-Rib liner sheets makes them easy to handle, transport, and install. Their flexibility allows them to be installed in difficult-to-reach areas and complex shapes, reducing labor costs and installation time.

-

Cost-Effective

- Compared to other corrosion-resistant materials like stainless steel or concrete coatings, HDPE T-Rib liner sheets offer a more affordable solution without compromising on performance. The cost savings also extend to reduced maintenance and repair costs over the lifespan of the liner.

-

Environmentally Friendly

- HDPE is a recyclable material, making it an eco-friendly option. In addition, its resistance to chemicals means fewer leaks and environmental hazards in applications like sewage treatment and landfill lining.

Conclusion

HDPE T-Rib liner sheets offer a versatile, durable, and cost-effective solution for protecting structures in a variety of industries. Whether you're looking to prevent corrosion in a chemical plant, waterproof a tunnel, or protect sewage systems from chemical exposure, HDPE T-Rib Liner Sheets Installation are an excellent choice. With their impressive durability, resistance to chemicals, and long lifespan, these liners ensure that structures remain safe and functional for decades.

Frequently Asked Questions (FAQs)

1. What is the lifespan of HDPE T-Rib liner sheets?

HDPE T-Rib liner sheets have an impressive lifespan, often exceeding 50 years in many applications. However, this depends on factors such as the environment they are installed in, exposure to UV radiation, and the level of maintenance provided.

2. Are HDPE T-Rib liner sheets resistant to UV radiation?

Yes, HDPE T-Rib liner sheets are resistant to UV radiation, making them suitable for outdoor applications. The material does not degrade easily under prolonged exposure to sunlight, which is an essential feature for projects like tunnel linings and landfill covers.

3. Can HDPE T-Rib liner sheets be installed on existing structures?

Yes, HDPE T-Rib liners can be retrofitted to existing structures to provide added protection. The sheets can be installed on concrete, steel, or other surfaces with the proper preparation to ensure effective adhesion and performance.

4. How do HDPE T-Rib liner sheets prevent root growth in underground applications?

In applications like waterproofing and landfill liners, HDPE T-Rib sheets act as an impermeable barrier that prevents roots from penetrating and damaging the structure. This root resistance is particularly important in protecting underground systems from plant growth.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness