The Role of Geonet in Road Construction: Enhancing Durability and Sustainability

Road construction has evolved significantly over the past few decades, with innovations focused on improving Pulkit Plastic Products the durability, longevity, and environmental impact of roadways. One such innovation that has garnered attention is the use of geonets. This article explores how Geonet In Road Construction, their benefits, and their role in creating sustainable infrastructure.

What is a Geonet?

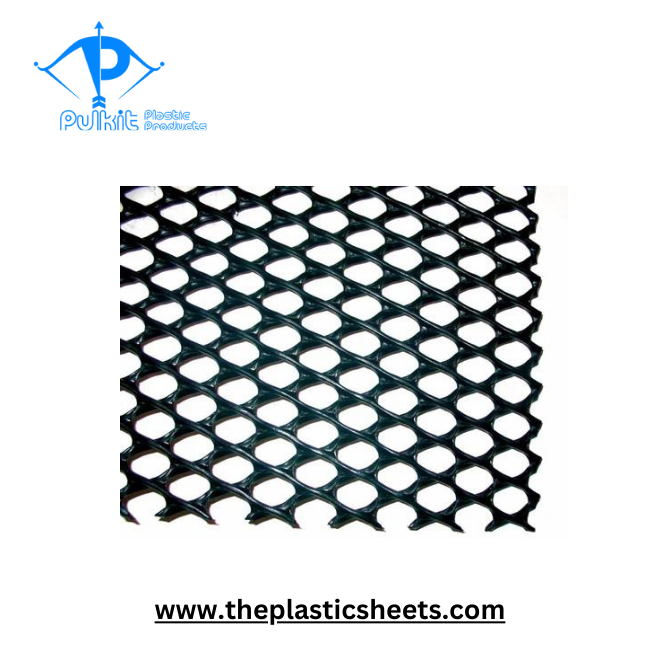

A geonet is a synthetic material typically made from high-density polyethylene (HDPE). It is designed in a grid or mesh-like structure and is commonly used in civil engineering and construction projects. Geonets are part of a larger family of geosynthetics, which includes geotextiles, geomembranes, and geogrids, all of which are designed to enhance the performance of soil and other materials used in construction.

Geonets are primarily used for drainage and reinforcement in road construction projects. Their main function is to prevent soil erosion, enhance drainage, and increase the overall stability of the roadway. By allowing water to flow through the grid while retaining the structural integrity of the road, geonets prevent moisture buildup, which is one of the leading causes of road degradation.

How Geonet is Used in Road Construction

1. Improving Drainage

Water is one of the main factors that cause roads to deteriorate. When water accumulates beneath a road, it can weaken the underlying soil, leading to cracks, potholes, and other forms of damage. Traditional road construction methods often involve complex drainage systems that can be expensive and difficult to maintain.

Geonets, however, provide a more efficient and cost-effective solution for managing water drainage. Their three-dimensional, open-mesh structure allows water to flow freely, ensuring that it does not accumulate under the road. This prevents the weakening of the base and sub-base layers of the road, significantly extending its lifespan. The geonet’s ability to maintain consistent water flow can also reduce the need for additional drainage installations, saving time and resources.

2. Reinforcement of Road Base

A strong foundation is essential for any road, especially when subjected to heavy traffic. One of the challenges in road construction is ensuring that the base layer remains stable over time. The natural shifting of soil, combined with the pressure from vehicles, can cause the base to weaken.

By integrating geonets into the road's sub-base or base layer, engineers can reinforce the structure, preventing excessive shifting and settling. Geonet Use In Road Engineering work by distributing the load evenly across a larger surface area, reducing the pressure exerted on any one point. This helps to maintain the road’s structural integrity, preventing cracks and dips that lead to potholes or uneven surfaces. This reinforcement is particularly beneficial in areas with soft or unstable soils, where traditional construction methods may not provide sufficient support.

3. Erosion Control

Soil erosion is another common problem in road construction, especially in areas with steep slopes or heavy rainfall. When soil is washed away from the sides of the road, it can lead to structural instability and costly repairs.

Geonets are often used to stabilize slopes and prevent soil erosion in these situations. Their grid-like structure holds the soil in place while still allowing water to flow through, reducing the likelihood of erosion. In many cases, geonets are used in combination with other erosion control methods, such as vegetation or retaining walls, to provide additional stability.

4. Sustainability and Environmental Benefits

Sustainability is becoming an increasingly important consideration in road construction. Traditional road-building materials, such as asphalt and concrete, have a significant environmental impact, both in terms of resource extraction and carbon emissions.

Geonets, by contrast, offer a more eco-friendly alternative. Because they improve drainage and reinforcement, roads built with geonets require less maintenance and repair, reducing the need for additional materials over the road’s lifetime. Additionally, geonets can be manufactured from recycled materials, further decreasing their environmental footprint. The use of geonets can also reduce the amount of aggregate and other natural resources required for construction, making road-building more sustainable overall.

Benefits of Using Geonet in Road Construction

1. Extended Road Lifespan

One of the primary advantages of using geonets is that they significantly extend the lifespan of the road. By improving drainage, reducing soil erosion, and reinforcing the base, geonets prevent many of the issues that lead to road degradation. As a result, roads built with geonets require less frequent repairs and maintenance, reducing overall costs and disruption to traffic.

2. Cost-Effective Solution

While geonets may represent an additional upfront cost, they can actually save money in the long term. By preventing damage and reducing the need for maintenance, geonets help to lower the overall cost of road construction. Additionally, their installation is relatively straightforward, requiring minimal labor and equipment compared to more traditional drainage and reinforcement methods.

3. Environmental Protection

As mentioned earlier, geonets contribute to more sustainable road construction practices. By reducing the need for raw materials and minimizing environmental damage, they help to protect natural ecosystems and reduce the carbon footprint of road-building projects.

4. Versatility

Geonets are highly versatile and can be used in a variety of road construction applications. Whether dealing with steep slopes, unstable soils, or heavy rainfall, geonets can be adapted to meet the specific challenges of a given project. This makes them an ideal solution for a wide range of construction environments, from urban roads to rural highways.

Conclusion

The incorporation of Geonets For Highway Construction offers numerous advantages, from enhancing the structural integrity and longevity of the road to promoting sustainability and reducing environmental impact. As infrastructure demands continue to grow, innovations like geonets will play an increasingly important role in creating durable, cost-effective, and environmentally friendly roadways.

FAQs

1. What are the key differences between geonets and other geosynthetics like geotextiles?

Geonets primarily function as drainage and reinforcement materials, allowing water to pass through their grid-like structure while maintaining the strength of the soil or other materials around them. Geotextiles, on the other hand, are used for separation, filtration, and reinforcement in road construction. They prevent the mixing of different layers of materials while still allowing water to pass through, but they do not provide the same level of drainage that geonets offer.

2. Can geonets be used in all types of soils?

Yes, geonets are highly adaptable and can be used in a wide variety of soil types. They are particularly beneficial in areas with soft, unstable soils where drainage and reinforcement are critical. However, engineers will need to assess the specific needs of the project to determine the best type of geonet and installation method.

3. How does geonet installation affect the overall cost of road construction?

While the upfront cost of purchasing and installing geonets may be higher than traditional materials, their long-term benefits far outweigh these initial expenses. Geonets reduce the need for frequent repairs and maintenance, extend the lifespan of the road, and lower the overall cost of ownership. Additionally, they are relatively easy to install, which can reduce labor and equipment costs.

4. Is the use of geonets limited to road construction, or can they be used in other types of infrastructure?

Geonets are not limited to road construction and can be used in a variety of infrastructure projects, including retaining walls, drainage systems, and erosion control measures for embankments or dams. Their versatility and durability make them suitable for many civil engineering applications.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness