The Rise of PP Woven Fabric A Pillar of Industrial Growth

Polypropylene woven fabrics have become indispensable in modern industries due to their versatility, durability, and cost-effectiveness. These fabrics are used across a wide range of applications, from packaging and agriculture to construction and infrastructure projects. India, in particular, has emerged as a major hub for PP woven fabric manufacturers, driven by the country’s growing industrial capacity, skilled workforce, and commitment to quality. In this article, we will explore the role of PP woven fabric manufacturers in India, the production process, and the factors that make these fabrics so essential in today’s global market.

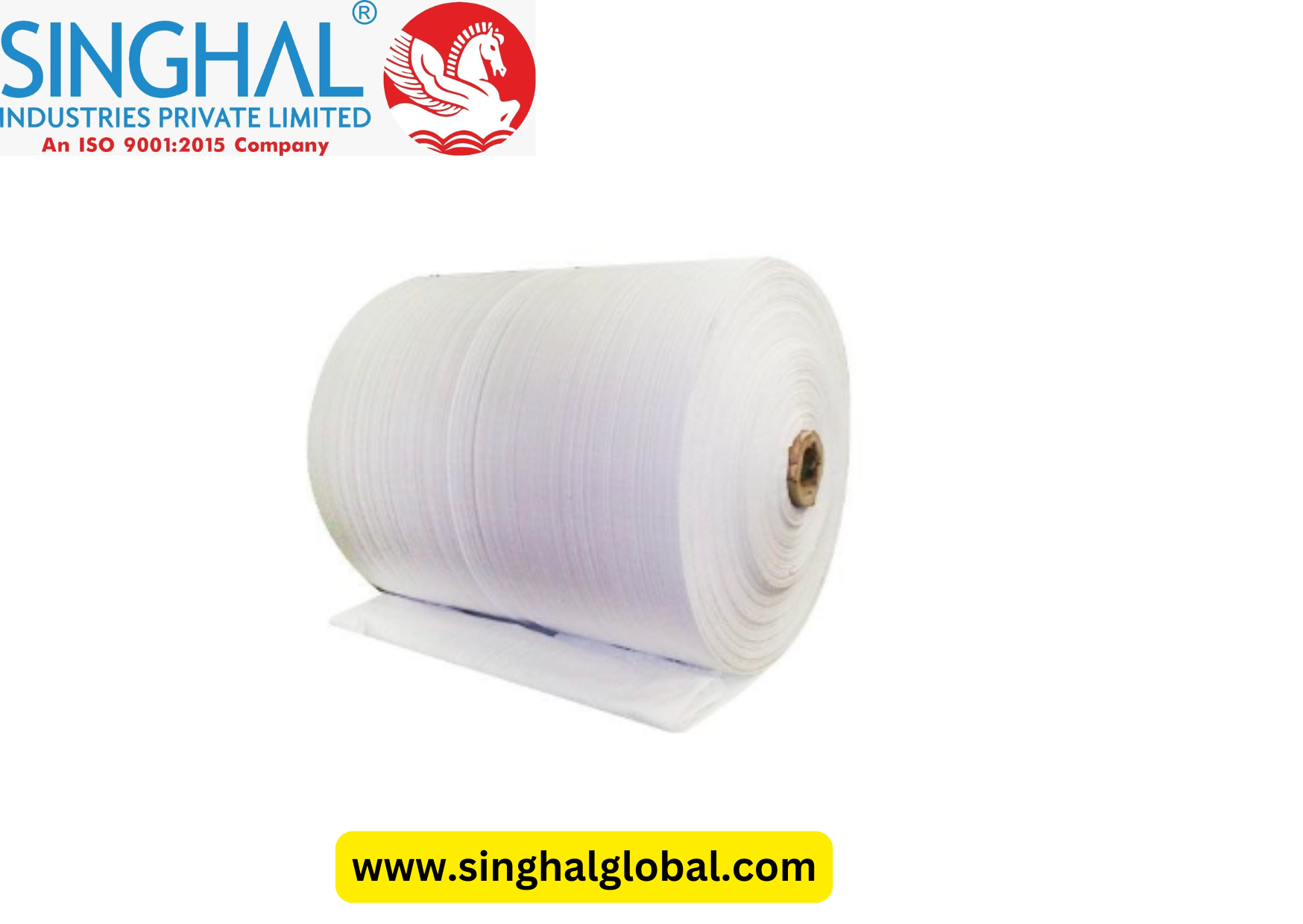

What Are Polypropylene Woven Fabrics?

Polypropylene woven fabrics, also known as PP woven fabrics, are made from interwoven polypropylene threads that are known for their strength, flexibility, and resistance to wear and tear. These fabrics are lightweight yet highly durable, making them ideal for heavy-duty applications. Polypropylene woven fabrics can be customized to meet the specific needs of various industries, including agriculture, construction, and packaging.

Due to the nature of their construction, PP woven fabrics offer high tensile strength, water resistance, and resistance to UV degradation, making them particularly suitable for outdoor uses. They are widely used for making products such as sacks, bags, ground covers, tarpaulins, and geotextiles.

Why PP Woven Fabric Manufacturers in India Stand Out

India’s manufacturing sector has seen tremendous growth over the last few decades, and PP woven fabric manufacturers in India have been a significant part of this industrial expansion. Several factors contribute to India’s prominence in the global PP woven fabric market:

-

Abundant Raw Materials: India has a reliable supply of polypropylene, which is the key raw material for producing woven fabrics. This ensures that manufacturers can source materials locally, reducing production costs and improving efficiency.

-

Skilled Workforce: India boasts a large, skilled workforce with expertise in textile production. This labor pool allows Indian manufacturers to produce high-quality PP woven fabrics at competitive prices. Skilled labor also enables these manufacturers to customize products according to client specifications, catering to global markets with diverse needs.

-

Cost-Effective Production: One of the primary reasons that PP woven fabric manufacturers in India are highly competitive in the global market is their ability to produce high-quality fabrics at relatively low costs. The combination of affordable labor, locally sourced materials, and advanced manufacturing technologies enables Indian manufacturers to offer cost-effective solutions without compromising on quality.

-

Export-Oriented Growth: India’s PP woven fabric industry has a strong export focus, with manufacturers shipping their products to countries across Europe, North America, and Asia. The country’s robust logistical infrastructure, including ports and transportation networks, supports these exports, making Indian manufacturers highly reliable suppliers in the global market.

-

Commitment to Sustainability: Many Indian manufacturers are adopting eco-friendly practices in the production of PP woven fabrics. These efforts include using recycled polypropylene, reducing energy consumption, and minimizing waste. As environmental sustainability becomes increasingly important to global buyers, this commitment positions PP woven fabric manufacturers in India as forward-thinking players in the industry.

The Production Process of Polypropylene Woven Fabrics

The process of manufacturing polypropylene woven fabrics involves several key steps:

-

Extrusion: The production begins with the extrusion of polypropylene resin, which is melted and transformed into thin plastic films. These films are then cut into narrow strips or threads.

-

Weaving: The polypropylene threads are woven together using specialized looms to create a fabric with a crisscross pattern. This woven structure gives the fabric its strength and flexibility.

-

Lamination (Optional): Depending on the end-use, the woven fabric may be laminated with a layer of polyethylene to make it waterproof or resistant to other environmental factors such as chemicals or UV rays.

-

Cutting and Stitching: The woven fabric is cut into specific sizes and, if required, stitched into products such as bags, tarps, or ground covers. These finished products are then packaged and shipped to customers.

-

Quality Control: Throughout the production process, manufacturers maintain stringent quality control measures to ensure that the fabrics meet industry standards for strength, durability, and performance.

Applications of PP Woven Fabrics

PP woven fabric manufacturer serve a wide range of industries, producing fabrics used in numerous applications:

-

Agriculture: In agriculture, polypropylene woven fabrics are used for making crop covers, ground covers, and sacks for storing grains, seeds, and fertilizers. These fabrics provide protection against environmental factors and pests while ensuring proper aeration and moisture control.

-

Construction: PP woven fabrics are commonly used in construction projects for purposes such as geotextiles, scaffolding covers, and protective wraps for building materials. Their high tensile strength and resistance to harsh weather conditions make them ideal for these demanding applications.

-

Packaging: One of the most common uses of polypropylene woven fabrics is in the packaging industry. The fabrics are used to manufacture bags and sacks for transporting goods like cement, sugar, chemicals, and animal feed. These bags are durable and can carry heavy loads, making them perfect for industrial packaging.

-

Transportation and Logistics: The durability and lightweight nature of PP woven fabrics make them ideal for use in transporting and storing bulk goods. They are used to manufacture bulk containers, tarpaulins, and pallet covers that protect goods during transit.

Why PP Woven Fabric Manufacturers Are Critical to Industrial Development

The production of polypropylene woven fabrics has grown in importance due to the versatility and wide range of uses across industries. From agriculture to packaging, construction, and transportation, the demand for durable, flexible, and customizable packaging solutions has made PP woven fabric manufacturers vital players in the global supply chain.

Manufacturers in India, in particular, are well-positioned to meet this growing demand. Their ability to produce high-quality fabrics at competitive prices, combined with their focus on innovation and sustainability, ensures that India remains a key hub for PP woven fabric production.

Conclusion

The demand for polypropylene woven fabrics is set to continue growing, driven by the need for durable, cost-effective, and environmentally friendly packaging and industrial materials. PP woven fabric manufacturers in India have established themselves as leaders in this field, offering high-quality products to meet the needs of industries worldwide. With their focus on sustainability, innovation, and cost-effective production, these manufacturers are well-equipped to maintain their position as key players in the global market.

Here are Related For pp woven fabric manufacturer

Q1: What are the main applications of polypropylene woven fabrics?

Ans: Polypropylene woven fabrics are commonly used in agriculture, construction, packaging, and logistics for applications such as sacks, ground covers, tarpaulins, and protective wraps.

Q2: How do PP woven fabric manufacturers ensure quality?

Ans: Manufacturers implement stringent quality control measures throughout the production process, from extrusion and weaving to cutting and stitching, ensuring that the fabrics meet industry standards for durability and performance.

Q3: Why are PP woven fabric manufacturers in India so competitive globally?

Ans: Indian manufacturers benefit from cost-effective production methods, abundant raw materials, a skilled workforce, and a strong export-oriented focus, making them highly competitive in the global market.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Игры

- Gardening

- Health

- Главная

- Literature

- Music

- Networking

- Другое

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness