The Role of HDPE Duct Couplers in India’s Growing Infrastructure

The rapid development of infrastructure in India has created an immense demand for reliable materials that can ensure durability, sustainability, and efficiency in construction projects. One such material that has become indispensable in modern piping systems is High-Density Polyethylene (HDPE). Specifically, HDPE duct coupler India products have become increasingly popular in the country's burgeoning telecom, electrical, and irrigation sectors. These couplers play a crucial role in connecting HDPE pipes, ensuring a secure, leak-proof fit that can withstand the rigors of different environmental conditions.

HDPE duct couplers are not only known for their strength but also for their ability to offer flexibility in installations, making them a preferred choice for both underground and above-ground piping systems. As India continues to expand its infrastructure, from rural electrification projects to urban telecommunications networks, the demand for these specialized couplers has skyrocketed. In this article, we will explore the importance of HDPE duct couplers, the role of HDPE pipe coupling suppliers , and the key benefits of using High-Density Polyethylene coupler products in various applications.

What is a HDPE Duct Coupler?

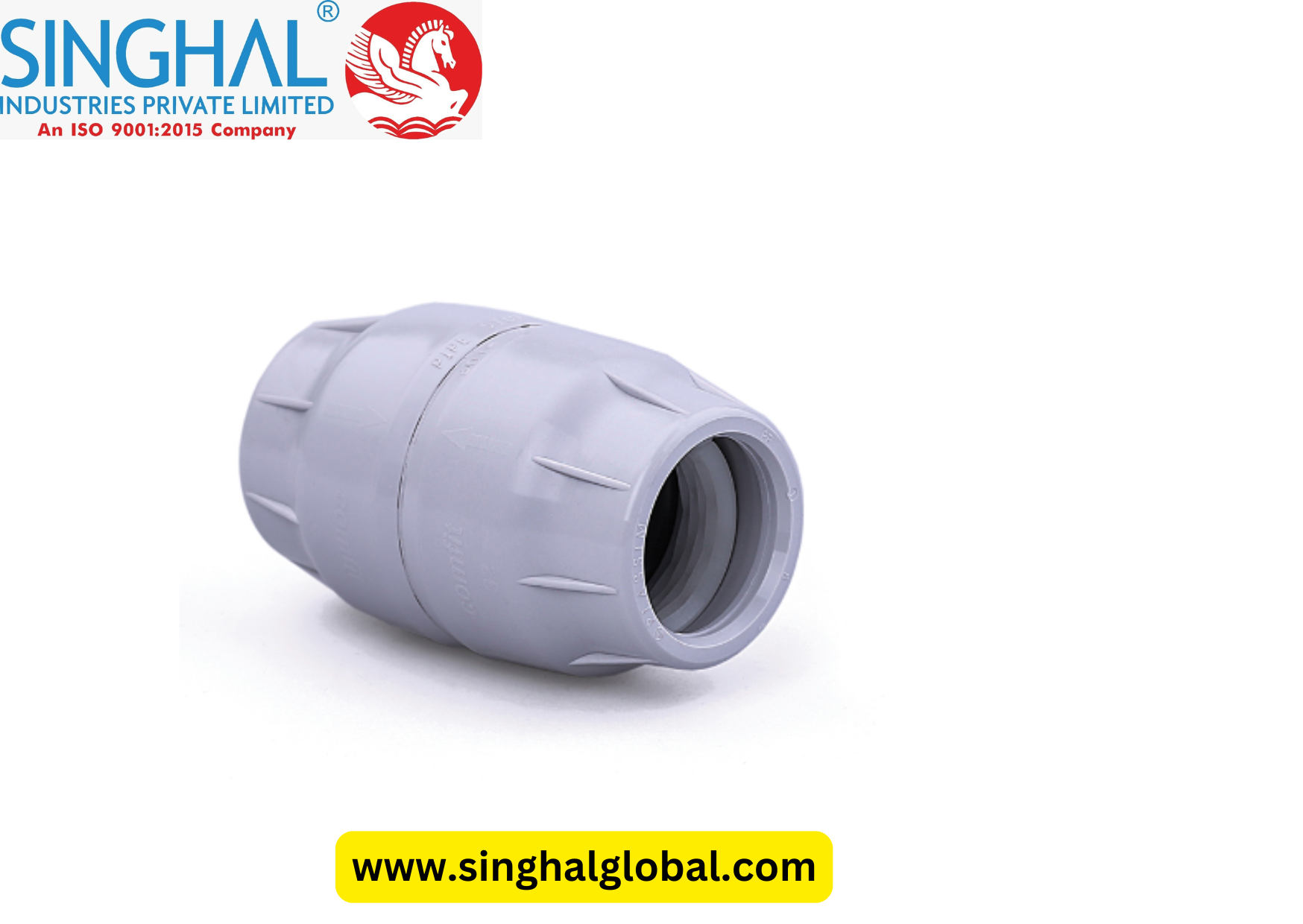

An HDPE duct coupler is a mechanical device used to join two sections of HDPE pipes. The primary function of these couplers is to ensure a secure connection between the pipes while preventing leaks and maintaining the integrity of the system. HDPE pipes are widely used for transporting water, gas, and telecommunications cables due to their durability, resistance to corrosion, and ability to withstand high pressures. The duct couplers are specifically designed to complement these properties, allowing for efficient installation and long-lasting performance.

In India, HDPE duct coupler India manufacturers are constantly innovating to meet the diverse requirements of the country's infrastructure projects. These couplers are available in various sizes and types, including push-fit and electrofusion couplers, making them versatile enough for different applications. Additionally, HDPE duct couplers are highly resistant to chemicals, making them suitable for use in harsh industrial environments.

The growing reliance on HDPE pipes and couplers in India is attributed to their ability to reduce installation time and maintenance costs. Unlike traditional materials like metal or concrete, HDPE offers a lightweight yet durable solution that simplifies the construction process, contributing to the efficiency of large-scale infrastructure projects.

The Importance of HDPE Pipe Coupling Suppliers

For any construction project, sourcing high-quality materials is essential. This is where HDPE pipe coupling suppliers play a crucial role. These suppliers provide essential components, such as duct couplers and pipe fittings, that ensure the seamless connection of HDPE pipes. The reliability of these suppliers is key to the success of any project, as poor-quality couplers can lead to significant problems, including leakage, pipe failure, and costly repairs.

HDPE pipe coupling suppliers in India are increasingly becoming an integral part of large-scale infrastructure projects. From water distribution systems to fiber-optic cable networks, the demand for HDPE pipe couplings is high, and reliable suppliers are needed to meet this growing demand. These suppliers must ensure that their products meet stringent quality standards to ensure they can withstand high pressure, temperature variations, and environmental factors.

As India moves towards its ambitious goals for improving national infrastructure, the role of HDPE pipe coupling suppliers has never been more critical. These suppliers are often involved in not only providing materials but also offering technical support and guidance on installation, ensuring that their products are used to their full potential.

Advantages of High-Density Polyethylene Couplers

One of the reasons High-Density Polyethylene Coupler products are favored in modern construction is their excellent properties. HDPE is a thermoplastic polymer made from petroleum, which gives it its distinct advantages, such as flexibility, resistance to corrosion, and an incredibly long lifespan. These qualities make HDPE ideal for both industrial and domestic applications.

The use of High-Density Polyethylene Coupler products in India has seen significant growth, particularly in sectors like telecommunications, irrigation, and gas pipelines. For example, in telecommunications, HDPE couplers are used to connect ducts that protect fiber-optic cables. In the water and gas sectors, they ensure that pipes can safely transport these resources without the risk of leaks or contamination.

A significant benefit of using HDPE couplers is their ability to be installed easily, without the need for complex machinery or extensive manpower. This reduces installation costs and speeds up project timelines. Moreover, HDPE couplers are highly resistant to chemicals and UV radiation, making them ideal for outdoor and industrial applications. Their ability to withstand extreme temperatures also makes them suitable for use in both hot and cold environments, ensuring consistent performance over time.

Furthermore, HDPE couplers are environmentally friendly. They can be recycled and reused in different projects, contributing to sustainable construction practices. This makes HDPE couplers an attractive choice for companies and governments that are looking to reduce their carbon footprint and adopt eco-friendly solutions.

HDPE Duct Couplers in Telecom and Electrical Infrastructure

The telecommunications sector is perhaps one of the most significant beneficiaries of HDPE duct coupler India products. With the increasing demand for high-speed internet and mobile connectivity, the need for robust infrastructure has never been more pressing. HDPE pipes and duct couplers are widely used in telecom networks to house and protect fiber-optic cables. These cables are delicate and need protection from environmental damage, and HDPE duct couplers provide a safe and reliable way to connect the pipes that house them.

Similarly, the electrical sector is utilizing HDPE duct couplers to lay underground cables. With the shift towards underground power grids to reduce the risk of damage from weather events, these couplers are becoming increasingly important. The strength and durability of HDPE duct couplers ensure that electrical cables remain protected from moisture, corrosion, and other environmental factors.

In both telecom and electrical infrastructure, the use of HDPE pipe coupling suppliers who can provide high-quality products ensures the longevity and safety of these systems. Reliable suppliers play a key role in the smooth execution of large projects, which in turn supports the country's development goals.

Conclusion

The rise of HDPE duct coupler India products in India's infrastructure landscape is a testament to the material's versatility, durability, and cost-effectiveness. As the country continues to invest in its water, gas, telecommunications, and electrical networks, the need for reliable HDPE duct couplers and HDPE pipe coupling suppliers will only increase. HDPE couplers not only ensure the integrity of these systems but also offer an environmentally friendly, sustainable solution that aligns with modern construction needs.

With their flexibility, strength, and ability to withstand a variety of environmental conditions, High-Density Polyethylene coupler products are setting new standards in the construction and infrastructure industries. Their widespread use is revolutionizing the way we build, ensuring that projects are completed more efficiently, cost-effectively, and sustainably.

Here are Related For High-Density Polyethylene Coupler

Q1: What are the key advantages of using HDPE duct couplers?

Ans: HDPE duct couplers offer flexibility, durability, resistance to corrosion, and ease of installation, making them ideal for both industrial and residential applications.

Q2: How do HDPE pipe coupling suppliers ensure the quality of their products?

Ans: Reliable HDPE pipe coupling suppliers adhere to stringent quality standards, using high-grade materials to ensure their couplers can withstand high pressure, temperature variations, and environmental stress.

Q3: In which sectors are High-Density Polyethylene couplers commonly used?

Ans: High-Density Polyethylene couplers are commonly used in sectors such as telecommunications, water distribution, gas pipelines, and electrical grids, providing reliable connections in both underground and above-ground systems.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness