Rockshield Mesh: A Vital Tool for Construction Projects

In the world of construction, ensuring the longevity and safety of pipelines, infrastructure, and other critical components is a priority. One product that has gained prominence in safeguarding buried pipelines and other sensitive structures is Rockshield Mesh for construction. This mesh acts as a protective barrier, effectively shielding pipelines from damage caused by sharp rocks, debris, and other elements during installation and in the long run. In this article, we explore the importance of rockshield mesh, its applications, and its relevance in various regions like India and Canada.

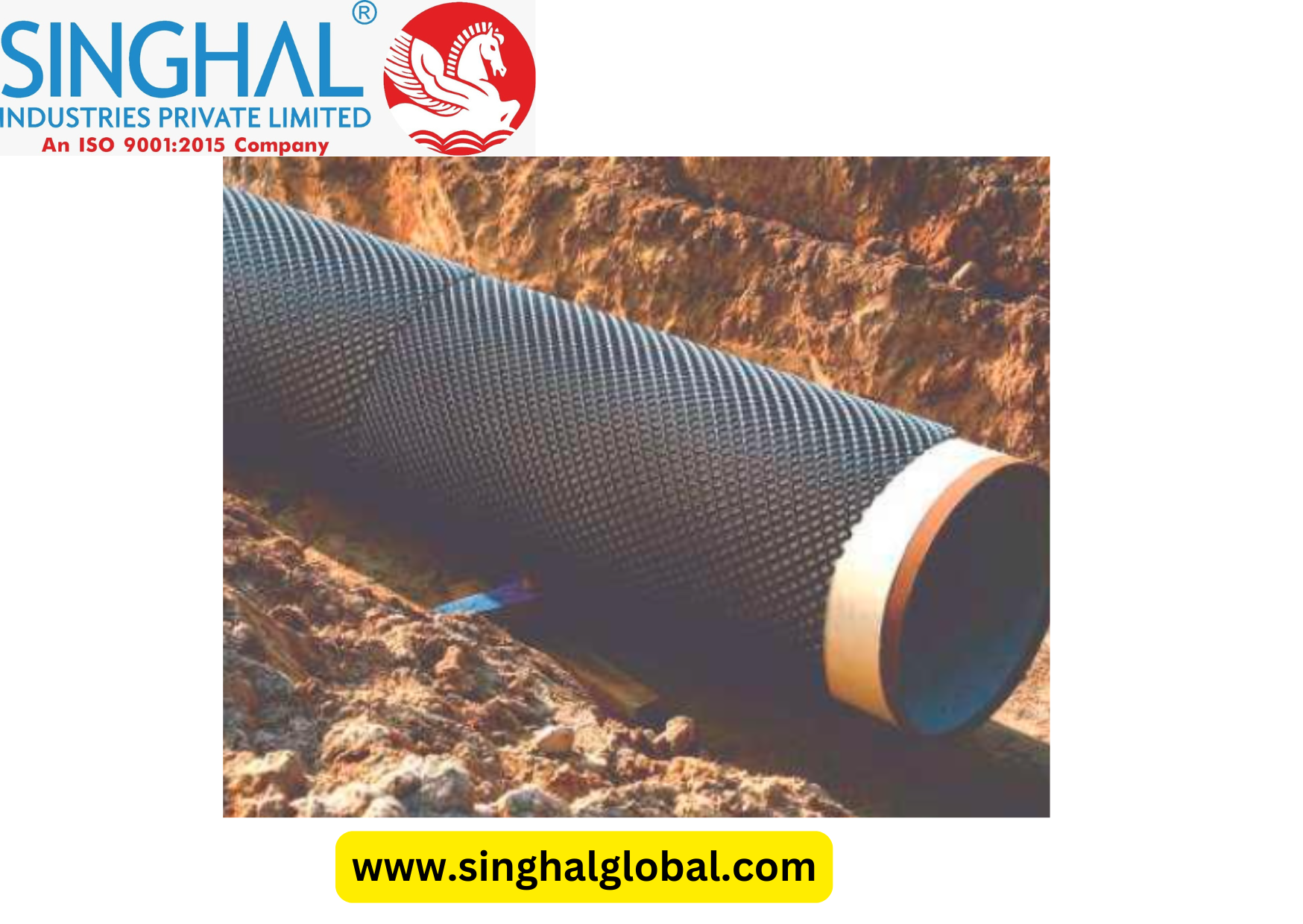

Rockshield Mesh for construction is a flexible, three-dimensional structure designed to provide an added layer of protection to pipelines and other underground infrastructure. The mesh prevents direct contact between rocks and pipes, reducing the risk of punctures, abrasions, or other damages that could lead to leaks or failures. As construction activities increase globally, this specialized material is becoming essential in sectors like oil and gas, water transportation, and other utility services that rely heavily on the integrity of underground systems.

Benefits of Rockshield Mesh for Construction

The need for Rockshield Mesh for construction is particularly critical in areas where pipelines are installed in rocky terrains. During excavation and backfilling, rocks can put significant pressure on pipes, leading to serious damage if not properly managed. This is where rockshield mesh comes into play, as it provides a cushioning effect between the rocks and the pipeline, minimizing contact and preventing scratches or dents.

In addition to protecting pipelines from physical damage, rockshield mesh also improves the overall durability and longevity of the installation. By preventing direct contact with rocks and other sharp objects, the mesh reduces the chances of corrosion, which can severely weaken a pipeline over time. Its open-grid structure also allows moisture and soil particles to pass through, ensuring that the pipeline stays dry and resistant to rusting.

The use of rockshield mesh is not limited to pipelines alone. It is also widely used in the protection of other underground structures like cables, tanks, and even foundations. By acting as a buffer between these structures and the surrounding environment, rockshield mesh helps maintain the integrity and performance of essential infrastructure over time.

Rockshield Mesh in India: A Growing Market

With the rise of infrastructure development projects across the country, the demand for Rockshield Mesh India has grown significantly. India’s rapid urbanization and expansion of its oil and gas sector have driven the need for robust pipeline protection solutions. Given the varied terrain and the need for pipelines to traverse challenging environments, Rockshield Mesh India has become an essential component in many construction projects.

India's construction industry, particularly in sectors like oil and gas and water supply, has recognized the value of this material for its ability to prevent damage to pipelines during the installation and operational phases. The mesh is also increasingly used in regions with rocky or uneven terrain, where the risks of pipe damage from external elements are particularly high. By incorporating rockshield mesh, Indian construction firms can ensure that their pipelines remain secure, reducing costly maintenance and repair work in the future.

India's expanding infrastructure, combined with the country's focus on improving pipeline safety and durability, has made it a key market for rockshield mesh. As projects continue to grow, the use of advanced protective materials like rockshield mesh is expected to increase, providing enhanced protection and longer-lasting installations.

Rockshield Mesh in Canada: Meeting Environmental and Safety Standards

In Canada, the need for Rockshield Mesh Canada has also gained traction, especially in the oil and gas industry. Canada's diverse and often harsh environmental conditions make the protection of pipelines a top priority. The country is home to extensive oil and gas networks that transport crude oil, natural gas, and other products across long distances, often through rugged terrain.

Rockshield Mesh Canada is particularly important in safeguarding pipelines from potential damage caused by freezing and thawing cycles, shifting soils, and rocky terrains. The mesh provides a necessary cushion between the pipeline and the surrounding environment, reducing the risk of punctures or other damage during and after installation. Given Canada’s focus on maintaining strict environmental and safety standards, the use of rockshield mesh ensures that the country's pipelines remain protected while minimizing the risk of leaks or failures that could have devastating environmental consequences.

In addition to its protective qualities, rockshield mesh is also an eco-friendly solution. Its open-grid design allows the natural movement of soil and moisture, preventing blockages that could harm the environment or hinder the performance of the pipeline. As Canada continues to expand its energy infrastructure, rockshield mesh is playing a crucial role in ensuring that these projects meet the highest standards of safety and reliability.

Applications and Installation

The application of Rockshield Mesh for construction extends beyond just pipelines. This protective mesh is used in various sectors, including utilities, mining, and telecommunications, where underground infrastructure is at risk of damage from surrounding debris and rocks. Whether protecting water pipelines, oil and gas conduits, or electrical cables, rockshield mesh offers an effective and affordable solution to ensure long-term protection.

Installation of rockshield mesh is straightforward, making it a preferred choice for many contractors. The mesh is wrapped around the pipeline or structure before backfilling with soil, creating a protective barrier that shields it from external damage. Because of its flexible structure, rockshield mesh can easily conform to irregular shapes and uneven surfaces, ensuring complete coverage.

The use of Rockshield Mesh India and Rockshield Mesh Canada has become increasingly popular due to its versatility and ease of installation. Its ability to protect critical infrastructure from external threats makes it an invaluable asset in both regions' construction industries.

Conclusion

The importance of Rockshield Mesh for construction cannot be overstated, particularly in projects involving underground infrastructure. This durable, flexible mesh is designed to safeguard pipelines and other structures from damage caused by rocks and other external elements during installation and beyond. Whether used in India's booming construction market or in Canada’s rigorous oil and gas industry, rockshield mesh plays a vital role in ensuring the safety and longevity of essential infrastructure.

Rockshield Mesh India and Rockshield Mesh Canada are both growing markets for this protective material, with increasing demand driven by the need for reliable pipeline protection in various terrains. As construction projects continue to expand, the use of rockshield mesh is expected to rise, offering enhanced protection and ensuring the long-term success of infrastructure projects across the globe.

Here are Related For Rockshield Mesh India

Q1: What is the primary purpose of Rockshield Mesh in construction?

Ans: The primary purpose of Rockshield Mesh in construction is to protect pipelines and underground infrastructure from damage caused by rocks, debris, and other external elements during and after installation.

Q2: Why is Rockshield Mesh important in India?

Ans: Rockshield Mesh is important in India due to the country's varied terrain and growing infrastructure projects, particularly in the oil and gas and water supply sectors, where it helps protect pipelines from external damage.

Q3: How does Rockshield Mesh perform in harsh environments like Canada?

Ans: In Canada, Rockshield Mesh is highly effective in protecting pipelines from damage caused by freezing and thawing cycles, shifting soils, and rocky terrains, ensuring long-term durability and safety of critical infrastructure.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Juegos

- Gardening

- Health

- Inicio

- Literature

- Music

- Networking

- Otro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness