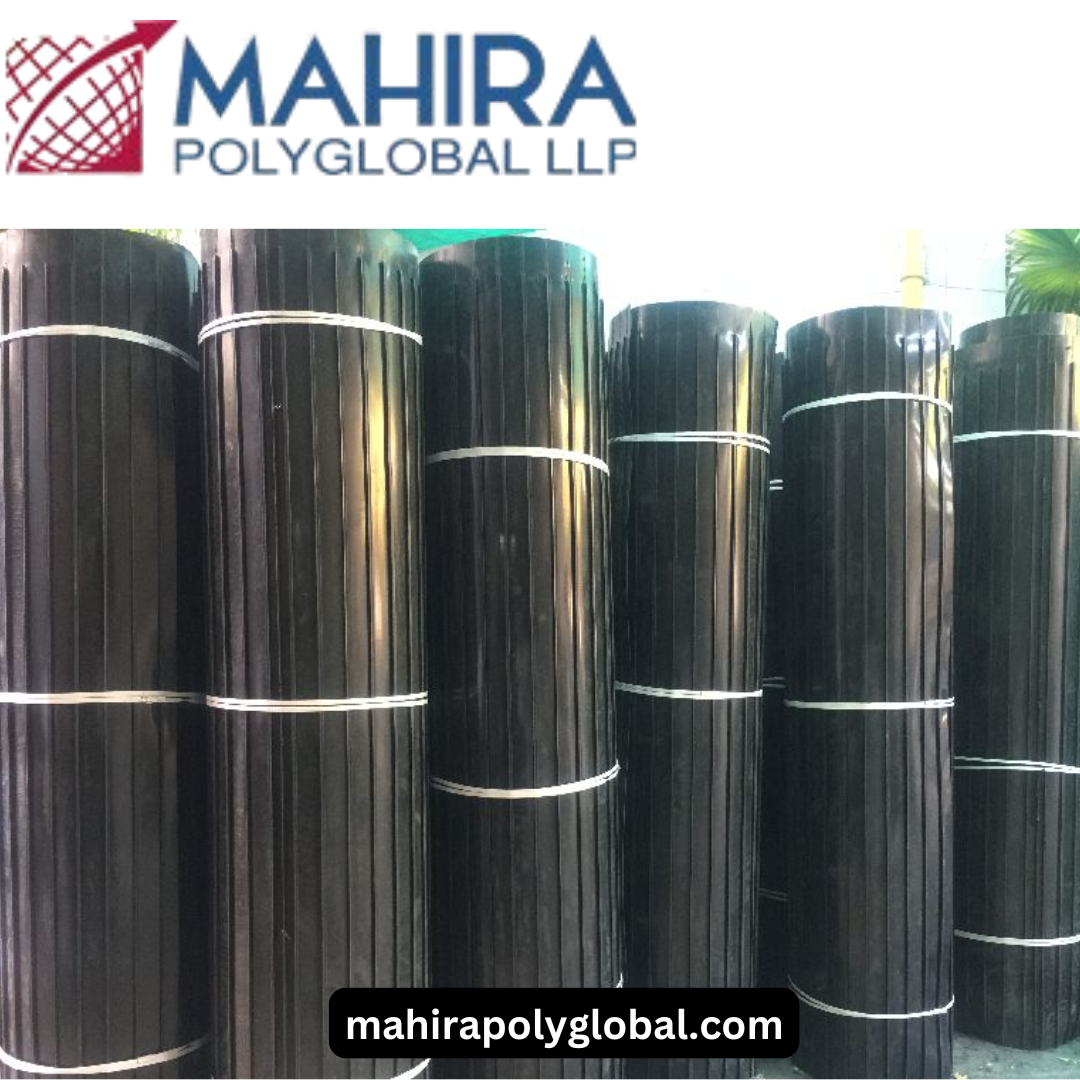

HDPE T-Rib Liner Sheets: The Ultimate Guide to Their Applications and Benefits

In industries like construction, mining, and water treatment, protection from corrosion, chemical attack, and abrasion is paramount. High-Density Polyethylene (HDPE) T-Rib liner sheets are a modern solution to these challenges. These sheets are known for their durability, flexibility, and resistance to environmental wear and tear. In this comprehensive guide, Mahira Polyglobal LLP explore what HDPE T-Rib liner sheets are, their benefits, applications, and address common questions surrounding their use.

What are HDPE T-Rib Liner Sheets?

HDPE (High-Density Polyethylene) is a thermoplastic polymer known for its high strength-to-density ratio, making it extremely durable and versatile. T-Rib Liner Sheets are specialized HDPE sheets designed with T-shaped ribs on one side. These ribs enhance the bonding strength between the sheet and the surface it’s applied to, typically concrete or steel structures. The primary purpose of these liners is to provide a barrier that protects against the harsh effects of chemicals, abrasion, and other corrosive elements.

HDPE T-Rib liner sheets are often used in situations where long-term protection from chemical and physical damage is critical. Thanks to their excellent resistance to aggressive environments, they are an ideal choice for industries that deal with chemicals, acids, or high-impact loads.

Benefits of Using HDPE T-Rib Liner Sheets

The popularity of HDPE T-Rib liner sheets can be attributed to their multiple benefits, which include:

1. High Resistance to Chemicals and Corrosion

HDPE is naturally resistant to a wide range of chemicals, including acids, alkalis, and salts. This makes it ideal for lining storage tanks, pipes, and water treatment facilities. The T-Rib liner sheets create a robust barrier, protecting the underlying surface from chemical corrosion and extending the structure’s lifespan.

2. Exceptional Abrasion Resistance

In industries such as mining and material handling, surfaces are subject to constant wear from abrasive materials. HDPE T-Rib liner sheets offer superior abrasion resistance, protecting surfaces from excessive wear and tear. This property makes them particularly useful in applications where heavy-duty mechanical stress is involved.

3. Excellent Bonding with Concrete and Steel

The T-shaped ribs on the liner sheets are designed to embed into the surface of concrete or steel, ensuring a strong and lasting bond. This creates a protective, waterproof lining that remains intact even under heavy stress or movement. Whether you’re working in water management systems or underground construction, this feature ensures longevity and reliability.

4. Low Water Absorption

HDPE T-Rib liner sheets have a very low water absorption rate, making them ideal for applications where moisture resistance is crucial. This property ensures that the liners do not degrade or lose effectiveness in wet environments, such as sewage systems or water tanks.

5. Flexible and Durable

Despite their toughness, HDPE T-Rib liner sheets are flexible, which allows them to accommodate structural movement without cracking or breaking. This flexibility is essential for applications where temperature fluctuations or heavy loads might cause expansion or contraction in the underlying surface.

6. UV and Weather Resistance

HDPE is highly resistant to UV radiation, which prevents the material from degrading when exposed to sunlight. This makes HDPE T-Rib liner sheets suitable for outdoor applications, ensuring that the liners maintain their integrity even in harsh environmental conditions.

7. Cost-Effective and Easy to Install

Compared to other lining solutions, HDPE T-Rib liner sheets are cost-effective and easy to install. Their lightweight nature reduces the cost of transportation and handling, while their flexibility simplifies the installation process, reducing downtime and labor costs.

Common Applications of HDPE T-Rib Liner Sheets

HDPE T-Rib liner sheets are used in a variety of industries due to their versatile properties. Here are some of the most common applications:

1. Sewage Treatment Plants

In sewage and water treatment facilities, tanks and pipes are exposed to corrosive chemicals and constant moisture. HDPE T-Rib liner sheets are used to line concrete and steel surfaces, protecting them from corrosion and abrasion. This ensures the structural integrity of the facilities, reducing maintenance costs and downtime.

2. Mining Industry

Mining operations involve the handling of abrasive materials, which can cause significant wear on equipment and surfaces. HDPE T-Rib liners are installed in chutes, hoppers, and other equipment to protect against abrasion and chemical exposure. The liners’ toughness and flexibility make them an ideal choice for the demanding conditions in the mining industry.

3. Chemical Storage Tanks

Chemical storage tanks are often lined with HDPE T-Rib sheets to protect the tank material from corrosive chemicals. The liners provide a barrier that prevents the tank from coming into contact with chemicals, ensuring its longevity and safety.

4. Landfill Liners

Landfill sites require durable liners to prevent leachate from contaminating the soil and groundwater. HDPE T-Rib liner sheets offer the necessary chemical resistance and flexibility to withstand the environmental conditions in a landfill, ensuring effective containment of harmful substances.

5. Tunnels and Underground Structures

Tunnels and other underground structures are often exposed to moisture and chemical attack from the surrounding environment. HDPE T-Rib liner sheets are used to line these structures, protecting the concrete or steel from water ingress, chemical corrosion, and mechanical damage.

6. Canal and Waterway Linings

Water management systems, including canals and reservoirs, rely on HDPE T-Rib liners to prevent seepage and protect the underlying structure from water erosion. Their low water absorption rate and flexibility make them an ideal solution for such applications.

How to Install HDPE T-Rib Liner Sheets

Proper installation of Lining sheet manufacturers is crucial for maximizing their performance and longevity. Here are the general steps involved in installing these liners:

1. Surface Preparation

The surface (usually concrete or steel) must be cleaned and free from debris, oil, or any loose materials. A smooth and clean surface ensures better bonding between the liner and the substrate.

2. Positioning the Liner

Once the surface is prepared, the HDPE T-Rib liner sheet is positioned carefully over the area to be lined. It is essential to ensure proper alignment and coverage, especially in areas where seams will be created.

3. Welding the Seams

HDPE T-Rib liner sheets are typically joined using heat welding. This process involves melting the edges of two sheets and pressing them together to create a seamless, waterproof bond. This ensures that the entire surface is covered with a continuous protective layer.

4. Anchoring the Liner

The T-shaped ribs on the liner are embedded into the concrete or steel surface, securing the liner in place. This process may involve casting the liner directly into concrete or using mechanical fasteners for steel surfaces.

Conclusion

HDPE T-Rib liner sheets offer a versatile, cost-effective, and durable solution for protecting structures from chemical corrosion, abrasion, and environmental damage. Whether you’re involved in water treatment, mining, or chemical storage, these HDPE T-Rib Sheet Price provide long-lasting protection that can significantly reduce maintenance costs and improve the lifespan of your infrastructure. Their ease of installation, flexibility, and resistance to harsh conditions make them a preferred choice across multiple industries.

Frequently Asked Questions (FAQs)

1. What is the lifespan of HDPE T-Rib liner sheets?

HDPE T-Rib liner sheets are extremely durable and can last for decades when properly installed and maintained. Their resistance to UV rays, chemicals, and mechanical wear ensures long-term performance.

2. Can HDPE T-Rib liner sheets be used in high-temperature environments?

HDPE T-Rib liners can withstand moderate temperatures, typically ranging between -40°C to 80°C. For extremely high-temperature environments, other specialized materials may be required.

3. Are HDPE T-Rib liner sheets environmentally friendly?

Yes, HDPE T-Rib liners are environmentally friendly. HDPE is a recyclable material, and its long-lasting durability reduces the need for frequent replacements, minimizing environmental impact.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Oyunlar

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness