PP Sheets: Versatile, Durable, and Cost-Effective Solutions for Multiple Applications

Polypropylene (PP) sheets are among the most versatile and widely used plastic materials in various industries today. Known for their strength, lightweight nature, chemical resistance, and cost-effectiveness, Price of PP Sheet have found applications in packaging, automotive parts, construction, healthcare, and more. These sheets are made from polypropylene, a thermoplastic polymer that offers excellent durability and flexibility while maintaining environmental sustainability due to its recyclable nature.

This Pulkit Plastic Products will explore what PP sheets are, their key features and benefits, common uses, and address frequently asked questions (FAQs) to provide a comprehensive understanding of this essential material.

What Are PP Sheets?

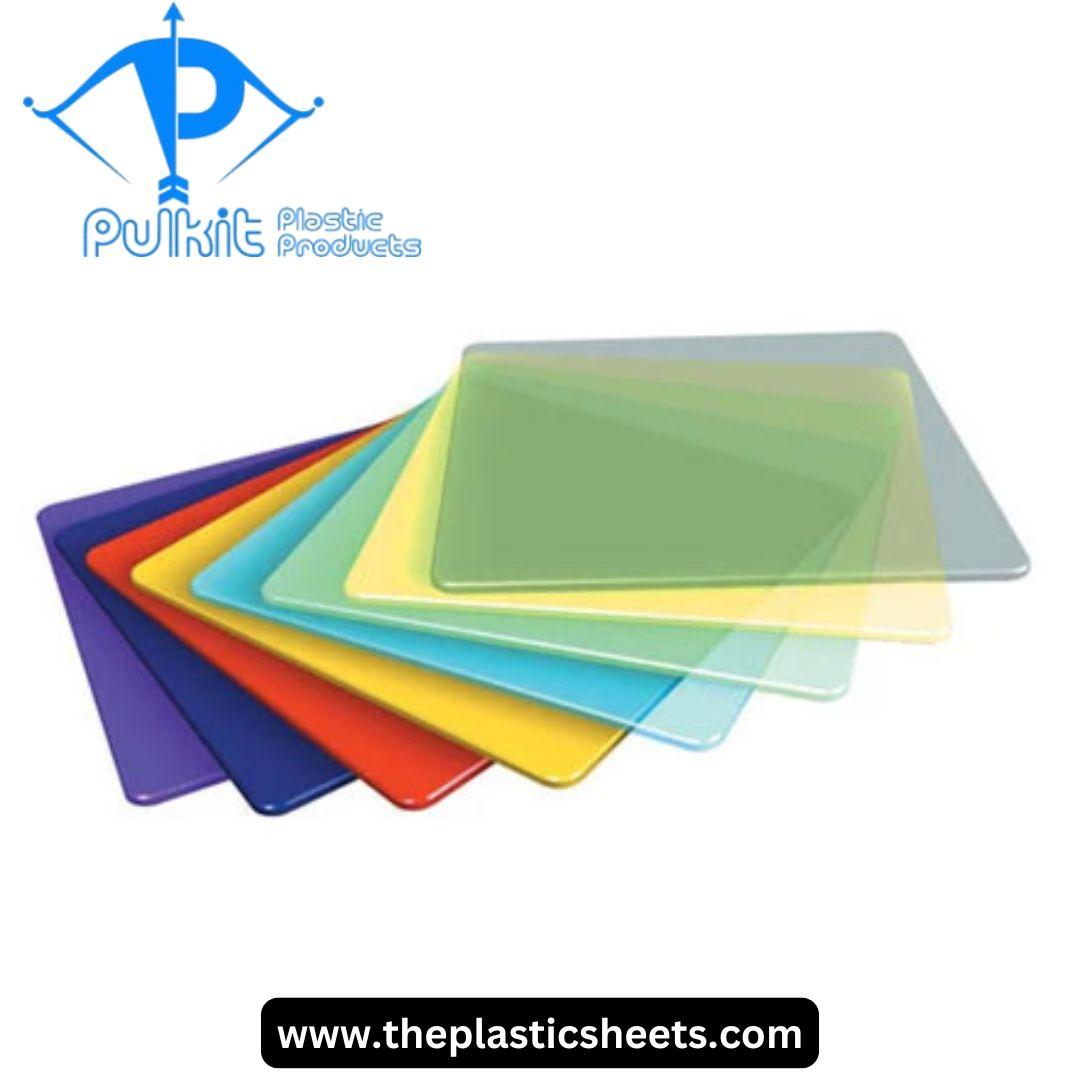

PP sheets are flat panels made from polypropylene, a thermoplastic material. Polypropylene is produced through the polymerization of propylene, which results in a plastic that is tough, heat-resistant, and chemically inert. PP sheets come in different thicknesses, colors, and grades, depending on the specific application. These sheets can be solid, corrugated, or even foamed, providing versatility in usage.

Polypropylene is widely chosen for its ability to withstand harsh conditions, such as exposure to chemicals, moisture, and temperature changes. PP sheets are lightweight, making them easier to handle and transport compared to other materials like metal or wood.

Key Features and Benefits of PP Sheets

The Price For Polypropylene offer several advantages that make them highly desirable in many industries. Here are some of the key features and benefits:

1. Chemical Resistance

One of the standout features of PP sheets is their high resistance to chemicals. Polypropylene is non-reactive to a wide range of substances, including acids, solvents, and alkaline solutions. This makes PP sheets particularly useful in chemical processing industries or environments where exposure to harsh chemicals is common.

2. Durability and Toughness

PP sheets are known for their exceptional durability. Despite being lightweight, they are strong and resistant to impact, making them ideal for applications where toughness is required. These sheets do not crack or break easily, even under stress, which adds to their long-term value.

3. Heat Resistance

Polypropylene has excellent thermal properties, which means it can withstand high temperatures without deforming or melting. PP sheets can tolerate temperatures up to 100°C, making them suitable for applications involving heat exposure, such as automotive parts and industrial containers.

4. Lightweight and Easy to Handle

PP sheets are significantly lighter than many other materials like metal or glass. This makes them easier to handle, transport, and install, reducing labor costs and improving overall efficiency.

5. Moisture and Water Resistance

Polypropylene does not absorb moisture, and it is naturally waterproof. This feature makes PP sheets ideal for outdoor applications and environments where humidity or water exposure is a concern.

6. Eco-Friendly and Recyclable

PP sheets are 100% recyclable, making them an environmentally friendly choice. Polypropylene can be melted down and reformed into new products, reducing waste and contributing to a circular economy. This recyclability also lowers the environmental impact compared to other non-recyclable materials.

7. UV Resistance

PP sheets can be manufactured with UV stabilizers, making them resistant to the harmful effects of sunlight. This feature is particularly beneficial for outdoor applications where prolonged exposure to sunlight could cause degradation in other materials.

8. Customizability

PP sheets are highly customizable. They can be made in various thicknesses, colors, and finishes, and can be easily cut, welded, or thermoformed into different shapes. This flexibility allows PP sheets to be tailored to meet specific industry needs and design requirements.

Common Uses of PP Sheets

Due to their numerous advantages, PP sheets are used across a wide range of industries. Some of the most common applications include:

1. Packaging

One of the primary uses of PP sheets is in the packaging industry. PP sheets are used to create everything from food containers and trays to bottle caps and industrial packaging materials. Their chemical resistance, durability, and lightweight nature make them ideal for protecting products during transportation and storage. They are also widely used for packaging medical devices, pharmaceuticals, and electronics.

2. Automotive Industry

In the automotive industry, PP sheets are used for interior and exterior parts of vehicles. Their high heat resistance, impact strength, and lightweight properties make them suitable for components like dashboards, bumpers, battery cases, and under-the-hood applications. PP sheets help reduce the overall weight of vehicles, improving fuel efficiency and performance.

3. Construction and Building Materials

PP sheets are also used in the construction industry for applications like wall cladding, roofing, and insulation. Their resistance to chemicals and moisture makes them an excellent choice for environments where durability and weather resistance are critical. PP sheets are also used in forming concrete molds and as protective barriers in construction zones.

4. Stationery and Displays

PP sheets are commonly used in the production of office supplies, such as binders, folders, and display covers. They are also used for making point-of-sale displays, signage, and advertising materials due to their ability to be easily printed on and their high durability.

5. Healthcare

PP sheets play a vital role in the healthcare industry, where they are used to manufacture medical devices, lab equipment, and packaging for pharmaceuticals. The chemical resistance and hygienic properties of polypropylene make it an ideal material for use in sterile environments.

6. Textile Industry

In the textile industry, PP sheets are used to create non-woven fabrics, which are then made into products like disposable masks, gowns, and filtration materials. The flexibility and strength of polypropylene make it suitable for producing lightweight, yet durable, textiles.

7. Household Goods

PP sheets are used in manufacturing various household products, such as storage containers, furniture, and kitchenware. Their heat resistance and food-safe properties make them ideal for producing items that come into contact with food, such as cutting boards, trays, and microwave-safe containers.

Conclusion

PP sheets are a versatile, durable, and cost-effective solution for a wide range of industrial and commercial applications. From packaging and automotive parts to construction and healthcare, the benefits of Polypropylene price are undeniable. Their chemical resistance, durability, lightweight nature, and recyclability make them a preferred choice in industries that demand high-performance materials. Whether you're looking for a material that can withstand harsh environments or simply need a reliable option for everyday use, PP sheets offer the perfect balance of strength, flexibility, and sustainability.

Frequently Asked Questions (FAQs)

1. What are the standard sizes of PP sheets?

PP sheets are available in various thicknesses, typically ranging from 0.5 mm to 25 mm or more. Standard sheet sizes can vary, but a common size is 4 feet by 8 feet (1.2 meters by 2.4 meters). However, manufacturers often offer custom sizes based on the specific requirements of the application.

2. Are PP sheets suitable for outdoor use?

Yes, PP sheets can be used outdoors. Polypropylene is naturally resistant to moisture, and UV-stabilized versions of PP sheets are available to withstand prolonged exposure to sunlight without degrading. This makes them an excellent choice for outdoor applications like signage, roofing, and construction materials.

3. Can PP sheets be recycled?

Yes, PP sheets are 100% recyclable. Polypropylene can be melted down and reprocessed into new products, making it an environmentally sustainable choice. This recyclability is one of the key advantages of using PP sheets, especially for industries looking to reduce waste.

4. How do you cut or shape PP sheets?

PP sheets are easy to cut and shape. They can be cut using standard cutting tools such as saws, knives, or laser cutters. Additionally, polypropylene sheets can be thermoformed, welded, or joined with adhesives to create custom shapes or designs for specific applications.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Startseite

- Literature

- Musik

- Networking

- Andere

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness