A Manufacturer's Perspective on Efficiency and Control

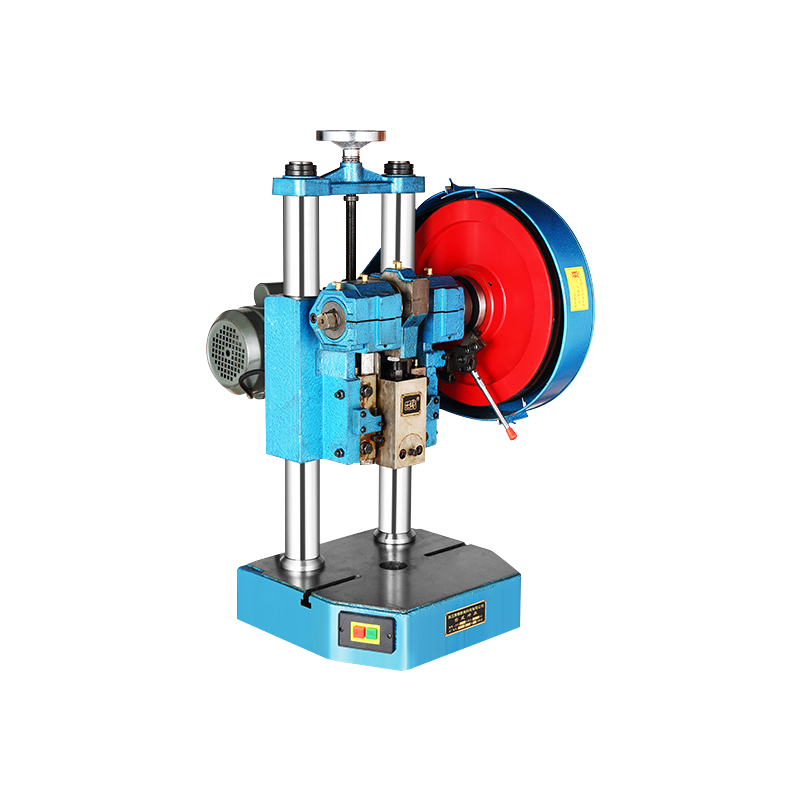

From a manufacturer's perspective, the Manual Punch Press is more than just a piece of equipment—it's a strategic investment in the production process. While automation has its advantages, the manual press offers a unique blend of control and efficiency that is hard to replicate with fully automated systems.

One of the key benefits of the Manual Punch Press is the ability to customize the punching process to fit specific production needs. Manufacturers can adjust the force and speed of the press to accommodate different materials and thicknesses, ensuring optimal results without the need for expensive tooling changes. This flexibility is particularly valuable for small-batch production or when prototyping new designs.

The manual press also allows for immediate feedback and adjustments. Operators can quickly identify and correct any issues on the fly, reducing the risk of defects and scrap. This real-time interaction with the machinery fosters a deeper understanding of the production process, leading to continuous improvement and innovation.

Moreover, the Manual Punch Press is an economical choice for businesses with limited budgets. It requires less upfront investment compared to automated systems and offers a lower cost per part for small to medium production runs. This cost-effectiveness, combined with the control it provides, makes the manual press an attractive option for many manufacturers.

In conclusion, the Manual Punch Press is a valuable asset in the manufacturing world, offering a balance of control, efficiency, and cost-effectiveness that is difficult to match with fully automated alternatives. It remains a popular choice for those who value the precision and personal touch that only a manual operation can provide.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spellen

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness