The Application of Cemented Carbide Cutting Tools in the Shipbuilding Industry

Applications of Cemented Carbide Cutting Tools in Shipbuilding

Hull Processing

In the shipbuilding industry, hull processing is a critical step. The application of cemented carbide cutting tools in hull processing is mainly reflected in the following aspects:

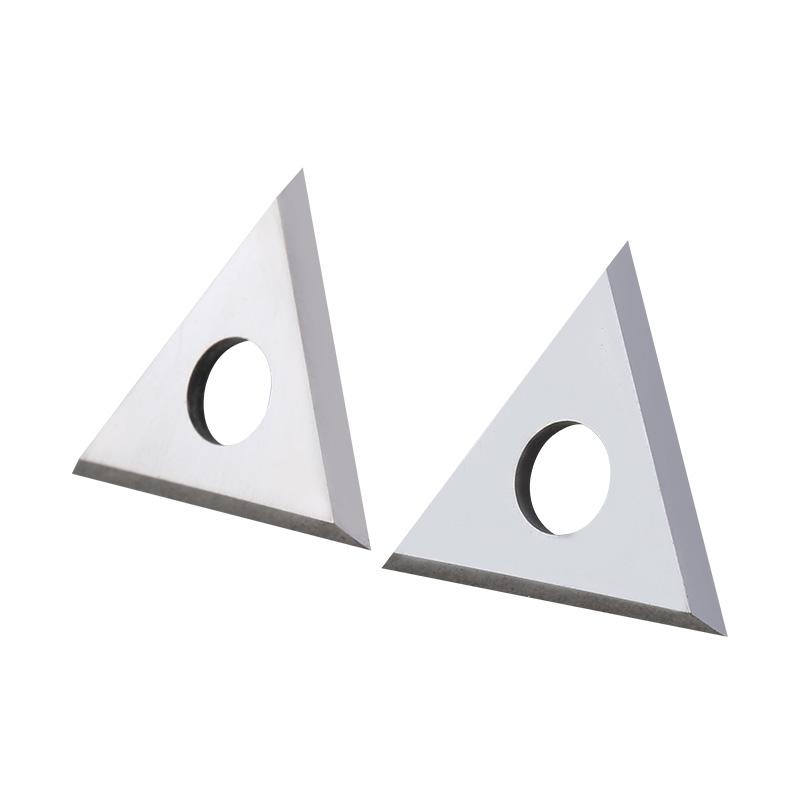

Cutting: Cemented carbide cutting tools can efficiently cut steel plates of various thicknesses, ensuring the flatness and precision of the cutting surface. This is essential for maintaining the structural integrity and aesthetic appearance of the ship.

Welding: Cemented carbide welding tools can effectively reduce welding defects and improve welding quality. High-quality welds are crucial for the structural strength and safety of the ship.

Shaping: Cemented carbide shaping tools can ensure the smoothness and dimensional accuracy of the processed surfaces during hull shaping. This is particularly important for areas that require precise fitting and alignment, such as the bow and stern sections.

Engine Component Processing

Ship engine components have extremely high requirements for material performance and processing precision. The application of cemented carbide cutting tools in engine component processing includes:

Crankshaft Processing: Cemented carbide cutting tools can efficiently complete both rough and finish machining of crankshafts, ensuring dimensional accuracy and surface quality. The precision of the crankshaft directly affects the performance and longevity of the engine.

Gear Processing: Cemented carbide gear processing tools can ensure the meshing precision and transmission performance of gears during processing. Accurate gear machining is vital for the smooth operation and efficiency of the engine.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spellen

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness