How to Choose the Right Toughening Agent for Your Application

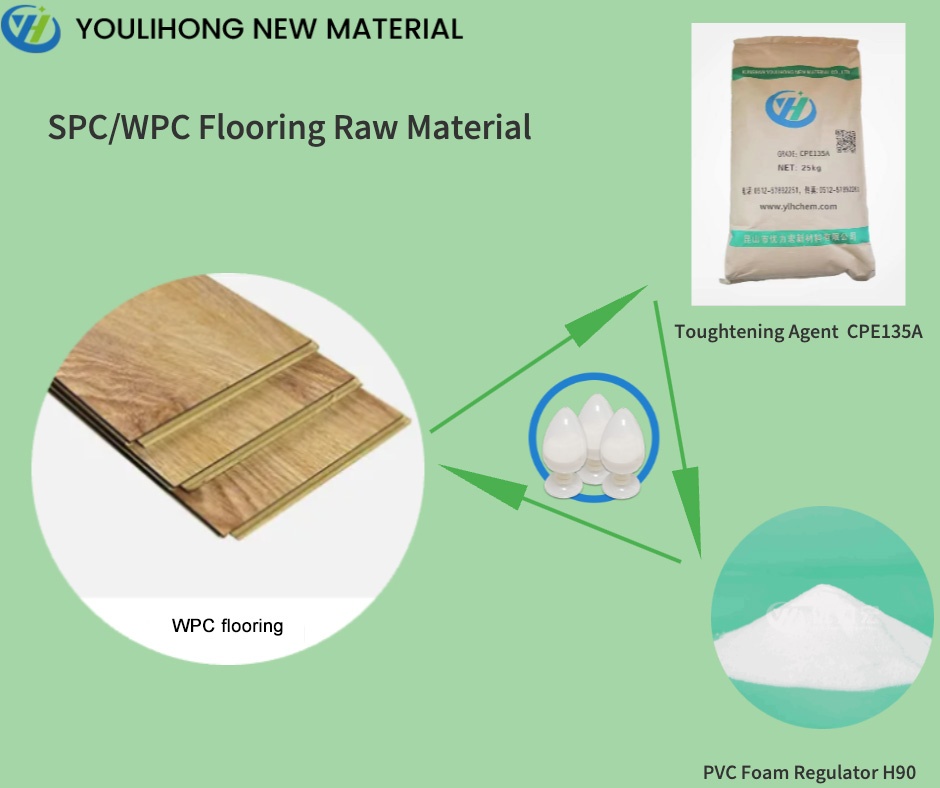

When it comes to enhancing the durability and performance of materials, selecting the appropriate toughening agent is crucial. Toughening agents are additives that improve the impact resistance, flexibility, and overall toughness of polymers, making them suitable for a variety of applications. In this guide, we will explore key factors to consider when choosing the right toughening agent for your specific needs, with a focus on Youlihong's toughening agents designed for SPC (Stone Plastic Composite), WPC (Wood Plastic Composite), and PE (Polyethylene) flooring.

1. Understand Your Material Requirements

Before selecting a toughening agent, it’s essential to understand the specific requirements of the material you are working with. Different applications may demand varying levels of toughness, flexibility, and resistance to environmental factors. For instance, if you are working with SPC or WPC flooring, you may need a toughening agent that enhances impact resistance while maintaining surface gloss.

Youlihong Toughening Agent Specifications:

- CAS No.: 64754-90-1

- Purity: 95%

- Application: Specifically designed for SPC floors, WPC floors, and various PVC products.

2. Evaluate Performance Characteristics

When choosing a toughening agent, consider its performance characteristics. Look for agents that offer:

- High Impact Resistance: Essential for applications where materials may experience sudden forces.

- Weather Resistance: Important for outdoor applications or environments exposed to moisture and UV light.

- Low Thermal Shrinkage: Reduces warping and dimensional changes during processing and use.

Youlihong's toughening agents provide excellent weather resistance and low thermal shrinkage, making them ideal for high-performance flooring solutions.

3. Compatibility with Base Materials

Ensure that the toughening agent is compatible with the base polymer you are using. Incompatibility can lead to poor dispersion, phase separation, or reduced mechanical properties. Youlihong’s toughening agents are formulated to work effectively with various PVC processing aids, ensuring optimal performance in SPC and WPC applications.

4. Consider Processing Conditions

The processing conditions under which the material will be manufactured can significantly influence your choice of toughening agent. Factors such as temperature, pressure, and processing speed should be taken into account:

- High-Speed Extrusion: If your application involves high-speed extrusion processes, select a toughening agent that can withstand these conditions without degrading.

- Ease of Use: Look for agents that can be easily incorporated into your production process without requiring extensive modifications.

Youlihong's toughening agents are designed for wide processing ranges and high-speed extrusion, ensuring efficiency in production.

5. Regulatory Compliance

Ensure that the toughening agent complies with relevant environmental and safety regulations. For instance, Youlihong’s products conform to EU environmental protection standards, making them suitable for various applications while prioritizing safety.

6. Packaging and Storage Considerations

Consider how the toughening agent is packaged and stored. Youlihong’s toughening agents are conveniently packed in 25 kg compound bags, making them easy to handle and store in a cool, dry environment away from moisture and heat sources.

Conclusion

Choosing the right toughening agent is essential for enhancing the performance of your materials in various applications. By understanding your material requirements, evaluating performance characteristics, ensuring compatibility with base materials, considering processing conditions, checking regulatory compliance, and taking packaging into account, you can make an informed decision.

For high-quality toughening agents specifically designed for SPC/WPC/PE flooring applications, consider Youlihong as your trusted partner. With our commitment to quality and performance, we provide solutions that meet your needs while ensuring optimal results in your production processes. If you have any inquiries or require further assistance in selecting the right toughening agent for your application, feel free to reach out!

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness