The Importance of Plastic Molding Injection Manipulators in Manufacturing

Plastic molding injection manipulators play a crucial role in the plastic injection molding process. These automated systems are designed to enhance productivity by handling plastic parts during and after the molding cycle. By performing tasks such as part removal, insertion, and assembly, manipulators reduce manual labor and improve precision.

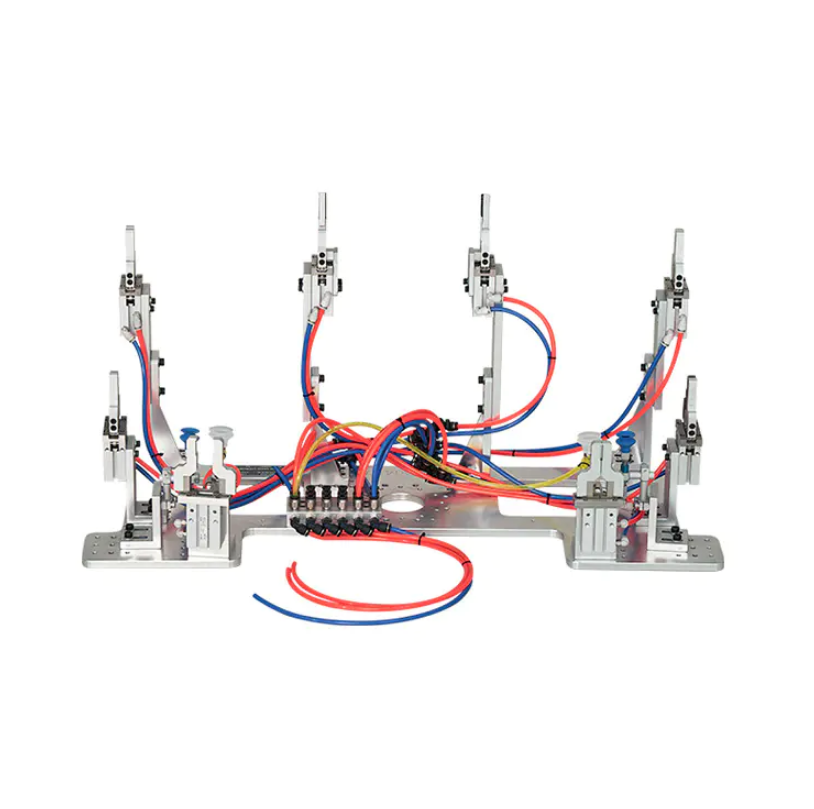

In a typical injection molding operation, the manipulator works in tandem with the injection molding machine. After the plastic has been injected into the mold and solidified, the manipulator is responsible for removing the part and placing it into an appropriate container. Some models are equipped with advanced features such as adjustable arms and suction devices, which help handle a variety of part shapes and sizes.

The use of manipulators offers several benefits to manufacturers. They improve production efficiency by decreasing cycle times and minimizing human error. Additionally, they enhance workplace safety by eliminating the need for operators to handle hot or heavy parts.

In summary, plastic molding injection manipulators are vital for automating processes, improving precision, and enhancing safety in manufacturing environments.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness