Exploring the Benefits of Aluminum Composite Panel Production Line in Modern Construction

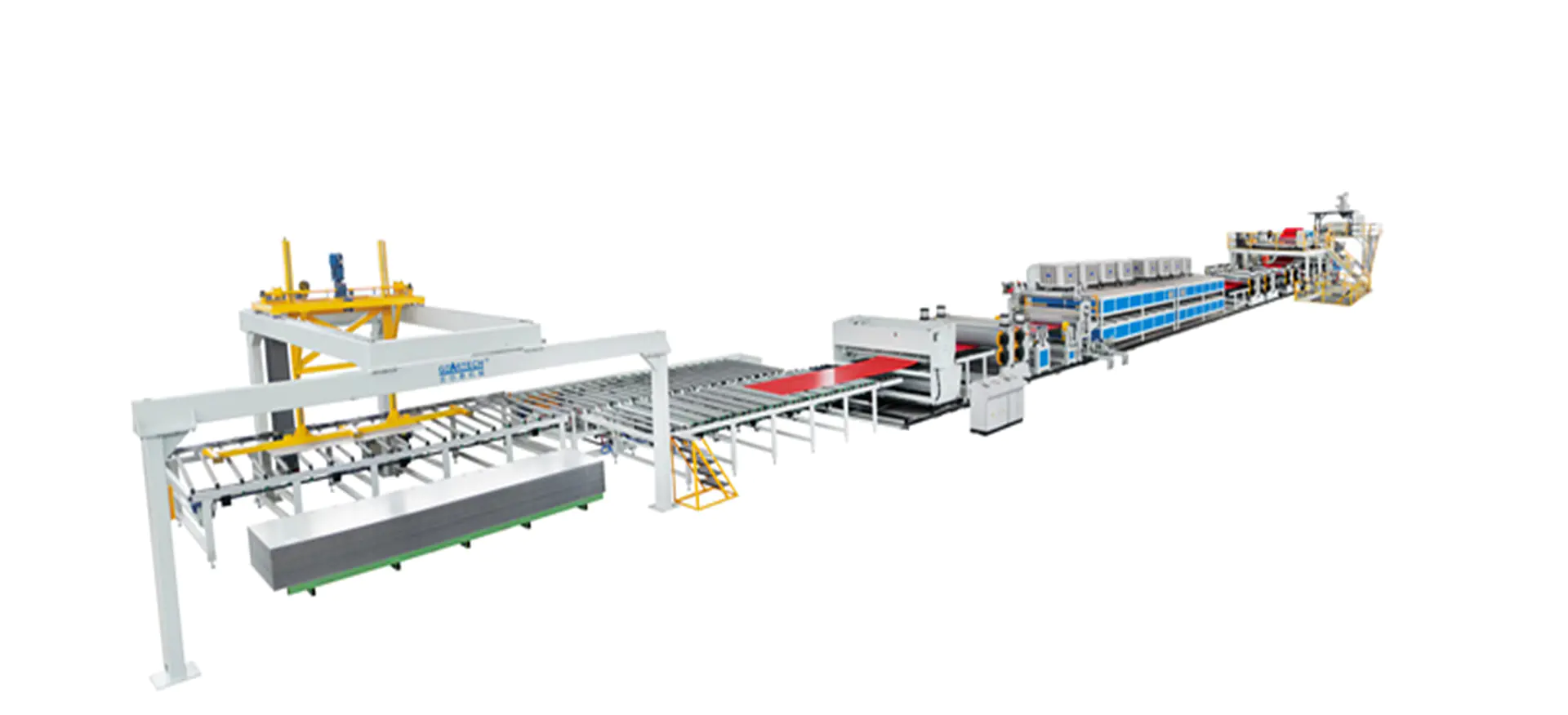

The aluminum composite panel production line has become an essential part of modern construction, offering a versatile solution for architects and builders. ACPs are used widely for their durability, aesthetic appeal, and ease of installation, making them the material of choice for building facades, interior designs, and even signage. The production line for aluminum composite panels is engineered to maximize efficiency, enhance quality, and meet the rising demand for this advanced material.

At the core of the ACP production line are several key processes: aluminum sheet bonding, surface treatment, coating, and panel cutting. The production begins with the selection of high-quality aluminum sheets. These sheets are then bonded to a non-aluminum core, typically made from polyethylene (PE) or fire-resistant mineral core materials. This sandwich structure gives ACPs their unique combination of strength and flexibility.

Once the core and sheets are bonded, the panels undergo a surface treatment, which can include processes like chemical etching or anodizing. This treatment ensures the panel’s surface is clean and ready for the application of coatings. High-performance coatings, often made of PVDF (polyvinylidene fluoride) or polyester, are applied to the surface, providing both aesthetic qualities and increased resistance to weathering and corrosion. These coatings also help in maintaining the panel’s appearance for extended periods, even in harsh environments.

After coating, the panels are cut into the desired sizes using advanced cutting technology. The precision of this process is vital, as ACPs must fit seamlessly into the architectural design. Some production lines also feature systems for perforating the panels, enabling custom designs or ventilation solutions.

The rise of aluminum composite panels can be attributed to their many advantages, such as their lightweight nature, which reduces transportation costs and simplifies installation. ACPs also offer high thermal insulation and soundproofing properties, contributing to energy-efficient buildings. Furthermore, they are highly customizable in terms of colors and finishes, allowing architects to explore creative possibilities.

For manufacturers, investing in a high-quality ACP production line provides a competitive edge. Automated systems ensure consistency, reduce labor costs, and minimize production waste. Additionally, such lines can scale production to meet growing demand in the global market.

In conclusion, the aluminum composite panel production line is a critical component of the construction industry. By enabling efficient manufacturing, these lines help meet the demand for high-quality, sustainable, and visually appealing building materials. The continuous advancements in production technology promise even greater innovation and efficiency in the years to come.

https://www.coating-line.com/product/acp-production-line.html

Application of Product and characteristics:

The final product ACP can be widely used in field of construction decoration such as curtain wall, interior and exterior wall of building,ceiling,column,storefront,billboard,exhibition rack,and auto etc.

1.High capacity and various thickness from 1mm to 8mm ;

2.The thickness range of Aluminum coil covers 0.018mm-0.5mm ;

3.Can use recycled PE ;

4.Stable technics and easy operation ;

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness