Pouch Pack Battery Testing Line: A Bridge Between Innovation and Production

As an important category of lithium-ion batteries, pouch pack batteries have shown immense potential across various fields. The pouch pack battery testing line serves as a bridge connecting scientific research and large-scale production, playing a crucial role in the development of the battery industry. This article will delve into the definition, characteristics, structure, and testing lines of pouch pack batteries.

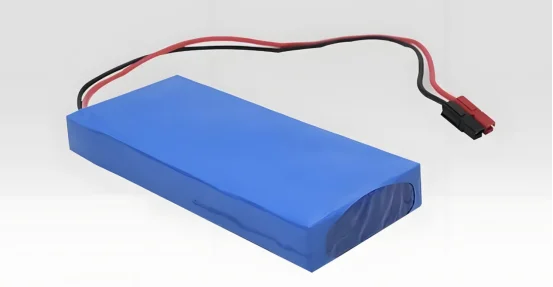

1. Definition of Pouch Pack Batteries

Lithium batteries are primarily categorized into three types based on their packaging form: cylindrical, square, and pouch pack. Pouch pack lithium batteries utilize an aluminum-plastic film to wrap a gel-like polymer electrolyte, featuring characteristics such as ultra-thin design and high safety. These batteries can be made into various shapes and capacities. When issues arise internally, pouch pack batteries typically swell at their weakest points rather than experiencing violent explosions, thus offering relatively higher safety.

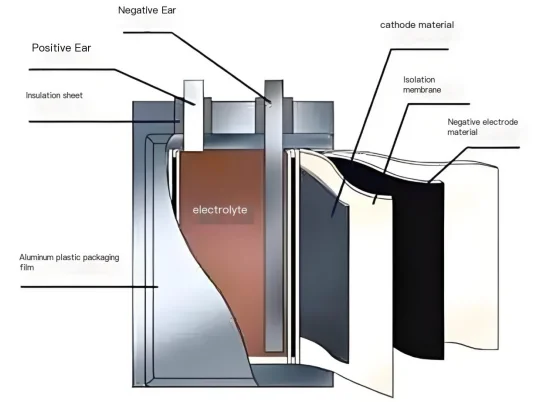

2. Structure of Pouch Pack Batteries

The basic structure of a pouch pack battery is similar to that of cylindrical and square batteries, consisting of key components such as the positive electrode, negative electrode, separator, insulating materials, positive and negative tabs, and the casing. However, unlike traditional steel or aluminum casings, pouch pack batteries are encapsulated using aluminum-plastic films.

3. Characteristics of Pouch Pack Batteries

(1)Safety Performance: The aluminum-plastic film packaging minimizes risks; in case of safety issues, Pouch pack batteries typically only swell or crack instead of exploding like steel or aluminum-cased cells.

(2)High Energy Density: Currently, mass-produced ternary Pouch pack power batteries have an average energy density of 240-250 Wh/kg, compared to 210-230 Wh/kg for ternary square (hard case) power batteries with the same material system.

(3)Lightweight: pouch pack batteries are about 40% lighter than steel-cased lithium batteries of equivalent capacity and 20% lighter than aluminum-cased ones.

(4)Lower Internal Resistance: Ternary pouch pack power batteries have lower internal resistance, significantly reducing self-discharge rates and enhancing performance while generating less heat and offering longer cycle life.

(5)Flexible Design: They can be manufactured in any shape and thickness according to customer requirements, allowing for the development of new cell models.

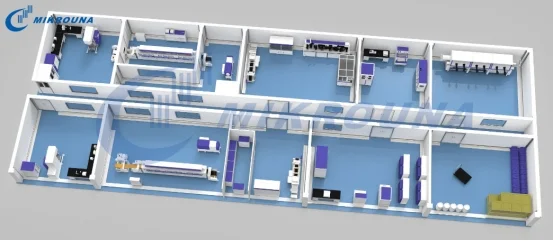

4. Pouch Pack Battery Testing Line

(1)Small-Scale Testing Line

The small-scale testing line for pouch pack batteries is specifically designed for research, development, and testing purposes. It allows researchers to explore new electrode materials by quickly fabricating sample batteries and assessing their performance metrics through data analysis to determine the material's research value.

(2)Pilot Testing Line

The pilot testing line is designed for small-scale production simulations. Once a new process is validated on the small-scale line, it can be simulated on the pilot line at a certain production scale to test feasibility. This line also helps identify potential issues during production, such as equipment compatibility and operational standards.

Through exploration on the small-scale line and simulation validation on the pilot line, the performance of Pouch pack batteries can continuously be optimized to meet diverse needs across different fields. The Pouch pack battery testing line provides essential support for R&D and production while contributing significantly to technological advancement and societal progress.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Juegos

- Gardening

- Health

- Inicio

- Literature

- Music

- Networking

- Otro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness