The Role of Induction Aluminum Circles in Cookware Manufacturing

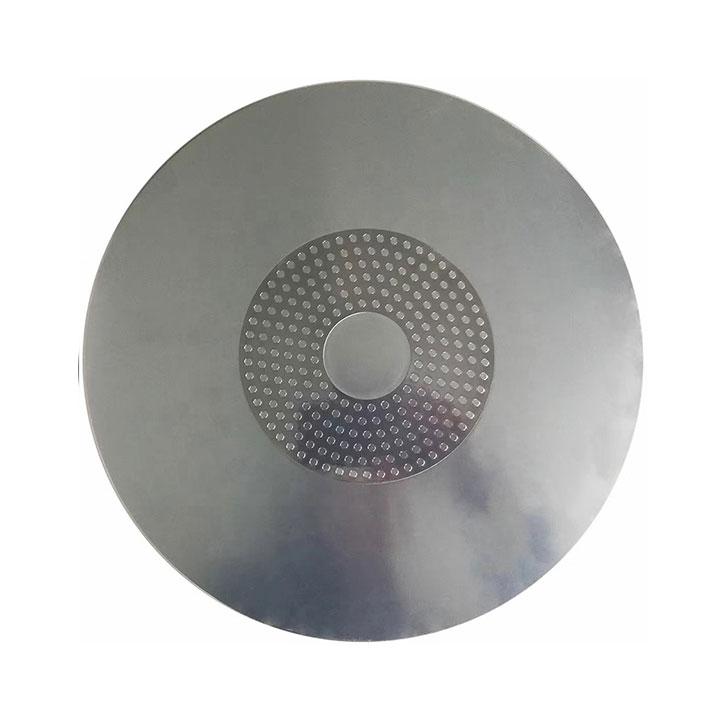

Induction aluminum circles have revolutionized the cookware industry, offering a perfect blend of functionality and efficiency. These pre-cut, flat aluminum discs are specifically designed for manufacturing pots, pans, and other cookware items compatible with induction stovetops. Let’s explore why induction aluminum circles are a game-changer for modern cookware production.

Why Aluminum Circles for Induction Cookware?

Induction cooking requires cookware with magnetic properties, which pure aluminum lacks. To address this, induction aluminum circles are often bonded with a ferromagnetic layer, such as stainless steel or iron, through cladding or coating processes. This hybrid structure allows the cookware to work seamlessly on induction stoves while retaining aluminum’s excellent heat conductivity. The result is even heat distribution, faster cooking times, and energy efficiency.

Manufacturing Advantages

Induction aluminum circles are precision-engineered to meet the demands of high-volume cookware production. Their uniform thickness and flatness ensure consistency in manufacturing, reducing material waste and improving production efficiency. These circles can be easily stamped, spun, or deep-drawn into various shapes, making them ideal for creating frying pans, saucepans, and woks. Additionally, their lightweight nature enhances user convenience, a key selling point for modern cookware.

Durability and Performance

The combination of aluminum and a ferromagnetic layer not only enables induction compatibility but also enhances durability. The bonded layers resist warping and corrosion, ensuring the cookware withstands high temperatures and frequent use. Furthermore, the aluminum core ensures rapid heat transfer, while the magnetic layer provides stability and strength.

Sustainability in Cookware Production

Aluminum is 100% recyclable, and induction aluminum circles contribute to sustainable manufacturing practices. Scraps generated during production can be recycled, minimizing waste and reducing the environmental footprint. As consumers increasingly prioritize eco-friendly products, the use of recyclable materials like aluminum in cookware aligns with market trends.

Conclusion

Induction aluminum circles have become indispensable in the cookware industry, offering a perfect solution for induction-compatible, high-performance cookware. Their versatility, durability, and sustainability make them a preferred choice for manufacturers aiming to meet the demands of modern kitchens. As induction cooking continues to gain popularity, the role of these specialized aluminum discs will only grow.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Oyunlar

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness