The benchtop punch press is a highly useful and compact machine designed for punching

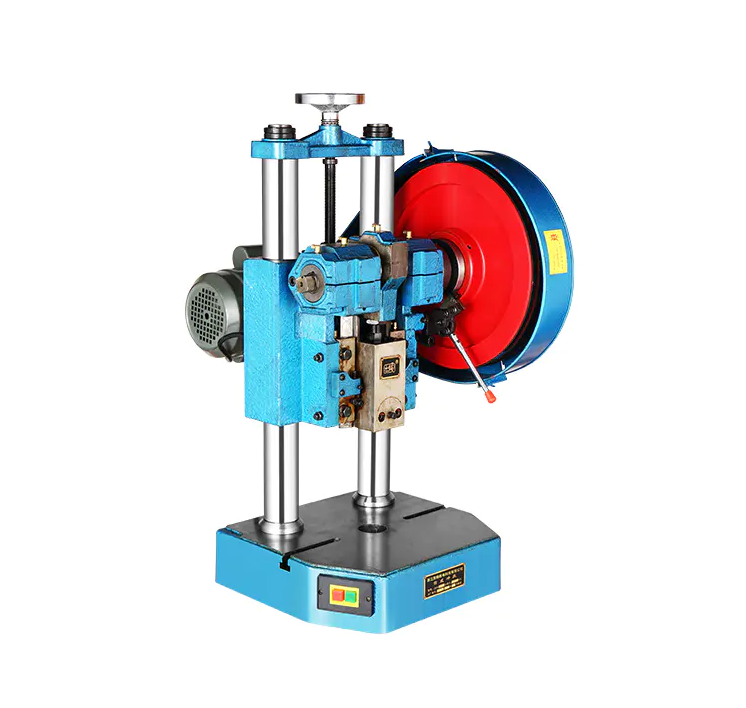

The benchtop punch press is a highly useful and compact machine designed for punching, shaping, and creating precise holes in various materials, particularly metal sheets. These machines are widely used in small workshops, fabrication units, and even educational settings due to their ease of use, affordability, and versatile capabilities. In this article, we will explore the applications and features of benchtop punch presses, highlighting their key advantages in a range of industries.

In the world of metalworking, the benchtop punch press is commonly used for creating holes, slots, and various cutouts in sheet metal. This makes it particularly valuable for small-scale fabrication and prototype development. For example, in automotive production, small components or parts that require precise perforations can be quickly and efficiently punched using this type of machine. The precision offered by benchtop punch presses is essential for ensuring that metal components fit together accurately during the assembly process.

In electronics manufacturing, benchtop punch presses are frequently used to create holes in metal sheets for components such as connectors, buttons, or other small electronic parts. This process is vital for ensuring that the metal parts can be properly aligned and mounted onto circuit boards or enclosures. In this sector, the speed and accuracy of a benchtop punch press reduce both labor costs and the time required for production.

For sign-making or graphic design, benchtop punch presses are ideal for cutting out patterns or logos from sheets of metal, plastic, or composite materials. This is particularly useful for custom signage or other decorative metal applications, where precision is essential for the design's aesthetic and structural integrity.

One of the key features of a benchtop punch press is its compact size, which makes it ideal for smaller workshops or businesses with limited space. Unlike larger, floor-mounted punch presses that take up considerable space, a benchtop model can easily fit onto a workbench, allowing for efficient use of available space. This makes it a highly appealing option for small businesses, hobbyists, or shops that need to perform occasional punching without committing to the larger, more expensive machines.

Another important aspect of benchtop punch presses is their precision. These machines are capable of making highly accurate punches, which is particularly important for industries like electronics, automotive, and manufacturing, where tight tolerances are required. By using adjustable dies and punch tools, operators can customize the size and shape of the holes or cutouts, ensuring that each part meets the exact specifications of the project.

Benchtop punch presses are versatile and compact tools that provide precision, speed, and ease of use in a variety of applications. Their ability to create accurate holes and cutouts in metal, plastic, and composite materials makes them essential in sectors such as metalworking, electronics manufacturing, sign-making, and prototyping. With their compact design, ease of operation, and customizable features, benchtop punch presses offer small businesses, workshops, and hobbyists a cost-effective solution for their punching needs. Whether used for small-scale production or one-off projects, these machines play a crucial role in enhancing efficiency and accuracy in a wide range of industries.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness