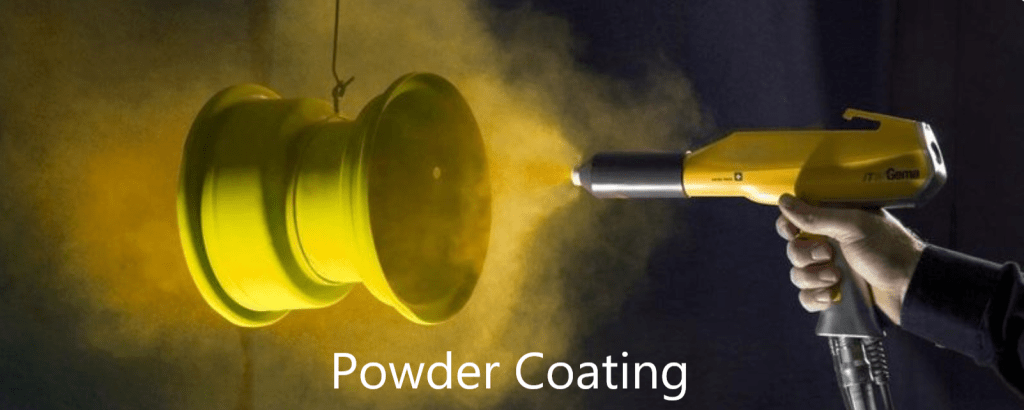

What Are the Benefits of Powder Coating?

Powder coating offers a range of advantages over traditional liquid painting methods, making it a popular choice for various industries. Here's a detailed look at its key benefits:

1. Durability and Longevity:

l Superior Resistance: Powder coatings are highly resistant to chipping, scratching, fading, corrosion, and weathering. This is due to the thermosetting process, where the powder melts and fuses to form a tough, protective layer.

l Long-lasting Finish: Properly applied powder coatings can last for many years, even in harsh environments, reducing the need for frequent recoating or maintenance.

2. Environmental Friendliness:

l Low VOCs: Powder coating emits very little or no volatile organic compounds (VOCs) during application and curing, making it a more environmentally friendly option compared to liquid paints that release harmful solvents.

l Reduced Waste: Overspray from powder coating can be collected and reused, minimizing waste and reducing the environmental impact.

3. Cost-Effectiveness:

l Efficient Application: Powder coating can be applied in a single coat, often achieving better coverage than multiple layers of liquid paint, saving time and labor costs.

l Less Material Waste: The high transfer efficiency of powder coating, combined with the ability to reuse overspray, reduces material waste compared to liquid painting.

l Lower Maintenance: The durability of powder coating translates to less frequent need for touch-ups or repainting, saving money on maintenance in the long run.

4. Versatility and Aesthetics:

l Wide Range of Materials: Powder coating can be applied to various materials, including metals, plastics, and even wood, expanding its range of applications.

l Variety of Colors and Finishes: Powder coatings are available in a vast array of colors, textures, and finishes, from smooth and glossy to textured and matte, allowing for design flexibility.

l Uniform Coverage: The electrostatic application process ensures even and consistent coating thickness, even on complex shapes and surfaces.

5. Other Advantages:

l Faster Curing: Powder coatings typically cure faster than liquid paints, reducing production time and turnaround.

l Improved Adhesion: The electrostatic charge helps the powder adhere strongly to the substrate, resulting in excellent adhesion and preventing peeling or blistering.

l Enhanced Performance: Powder coatings can provide specific functional properties, such as increased corrosion resistance, UV protection, or electrical insulation, depending on the formulation.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness