How Neodymium Magnet Density Affects Industrial Applications

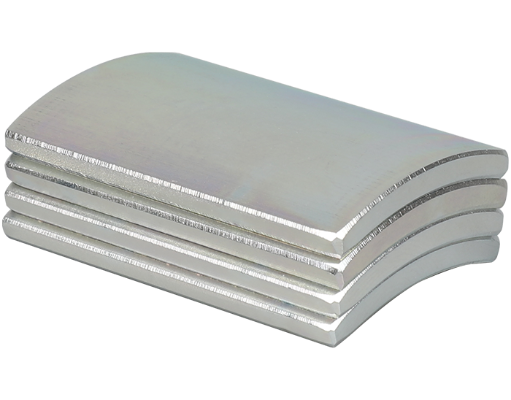

The neodymium magnets density directly affects the magnetic performance of these materials. Higher density typically correlates with a greater magnetic energy product, which is a measure of the magnet's ability to produce a magnetic field. For instance, sintered neodymium magnets, with neodymium magnets density higher, can achieve a magnetic energy product of up to 52 MGOe (Mega Gauss Oersteds), making them suitable for high-performance applications such as electric motors and generators.

Moreover, the neodymium magnets density influences the coercivity of the magnets, which is their ability to resist demagnetization. Sintered magnets, due to their higher density and more robust structure, generally exhibit higher coercivity than bonded magnets. This characteristic is particularly important in applications where the magnets are exposed to varying temperatures and magnetic fields, as it ensures that they maintain their magnetic properties over time.

Another aspect to consider is the impact of neodymium magnets density on the manufacturing costs. Sintered magnets, while offering good performance, are often more expensive to produce due to the complex processes involved in their creation. Bonded magnets, on the other hand, are less costly to manufacture, making them an attractive option for applications where high magnetic strength is not as critical.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Musica

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness