A Comprehensive Comparison of Injection Molding vs Die Casting

When it comes to manufacturing processes, both injection molding and die casting are widely used in the production of metal and plastic parts. Each method offers distinct advantages, depending on the materials, complexity, and volume of parts needed. In this article, we will explore both processes in detail, compare their strengths and weaknesses, and help you determine which one is right for your specific needs. By the end of this article, you’ll have a clearer understanding of injection molding vs die casting and be able to make an informed decision for your next manufacturing project.

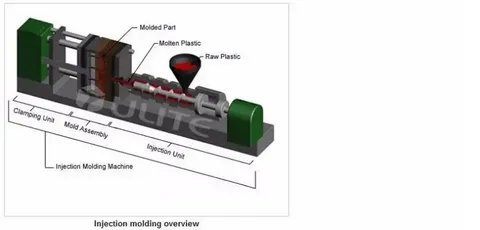

Understanding Injection Molding

Injection molding is a widely-used manufacturing process for producing parts from both thermoplastic and thermosetting plastic materials. The process involves injecting molten plastic into a mold at high pressure, where it solidifies and forms the desired part. Injection molding is ideal for producing parts in high volumes with tight tolerances and intricate designs. The process can be used for a variety of products, including toys, containers, automotive parts, and even medical devices.

The main advantage of injection molding vs die casting is its ability to create complex shapes with high precision. Once the molds are designed, they can be reused for mass production, which reduces production costs over time. Moreover, injection molding can handle a variety of plastic materials, including those with added fillers for enhanced strength, flexibility, or heat resistance. As a result, it’s a highly versatile method suitable for a wide range of industries, from consumer goods to automotive manufacturing.

What is Die Casting?

Die casting is a metalworking process that involves injecting molten metal into a steel mold, called a die, under high pressure. The metal solidifies inside the die and takes the shape of the cavity. Die casting is typically used for metals like aluminum, zinc, and magnesium, and is ideal for producing parts with complex geometries, tight tolerances, and high-quality finishes. It’s a common choice for industries such as automotive, aerospace, and electronics, where durable and lightweight metal parts are essential.

Like injection molding, die casting also allows for high-volume production and can create detailed parts with thin walls and tight tolerances. The dies used in die casting are expensive but can last for millions of cycles, making this process highly efficient for large production runs. The primary benefit of die casting is its ability to create strong, lightweight metal parts, which are often required in industries that need both performance and durability. When comparing injection molding vs die casting, the key difference is the materials used—plastic versus metal—and the types of applications they are best suited for.

Key Differences Between Injection Molding and Die Casting

When comparing injection molding vs die casting, one of the first things to consider is the material used. Injection molding primarily uses thermoplastic and thermosetting plastics, while die casting is typically limited to non-ferrous metals like aluminum, zinc, and magnesium. The choice of material can have a significant impact on the properties of the finished product, such as its strength, weight, and durability.

Another important difference between the two processes is the cost of tooling and molds. Injection molding generally requires lower upfront tooling costs compared to die casting, which involves the creation of metal molds that are much more expensive. However, the long-term cost efficiency of injection molding vs die casting can vary depending on the volume of parts being produced. While die casting molds are costly, they are highly durable and can last for millions of cycles, which may make them more economical for very high-volume runs.

Advantages and Disadvantages of Injection Molding

Injection molding offers several advantages, particularly for plastic parts. It allows for fast production rates, with cycle times often ranging from a few seconds to a few minutes. This makes injection molding an ideal choice for industries that require large quantities of identical parts, such as consumer goods or packaging. The process also allows for high precision and detail, making it perfect for complex designs that require tight tolerances.

However, injection molding vs die casting also has some drawbacks. One of the key challenges is the material limitation. While injection molding can handle various types of plastics, it cannot be used for metals or other high-strength materials, limiting its scope for certain industries. Additionally, while the initial tooling costs for injection molding may be lower than die casting, the molds themselves can still be expensive. Furthermore, plastic parts may not always offer the same level of durability or strength as metal parts produced via die casting, which is critical in certain applications.

Advantages and Disadvantages of Die Casting

Die casting offers distinct advantages, particularly when strong and lightweight metal parts are required. One of the primary benefits of die casting is the production of highly durable parts with excellent dimensional accuracy. The ability to produce thin-walled parts with complex geometries is another key advantage, making die casting ideal for industries like automotive and aerospace. Moreover, die-cast parts often have a smooth, high-quality surface finish, which can reduce the need for additional post-processing.

However, the injection molding vs die casting comparison reveals some limitations with the die casting process. While it’s ideal for metal parts, it is not suitable for plastic production. Die casting also comes with higher initial tooling costs, which may not be cost-effective for small production runs. Additionally, the die casting process is generally slower than injection molding, with cycle times ranging from a few seconds to several minutes, depending on the complexity of the part. As a result, die casting may not be the best choice for high-volume production of small parts, where injection molding excels.

Conclusion

Both injection molding vs die casting offer unique advantages and are suited for different manufacturing needs. Injection molding is ideal for high-volume plastic parts with intricate designs and precise tolerances. It is generally more cost-effective for smaller, lighter parts and allows for a wider range of material choices. On the other hand, die casting is the process of choice for producing strong, lightweight metal parts with high dimensional accuracy and durability. It is more suited for industries that require high-strength components, such as automotive and aerospace.

Ultimately, the choice between injection molding vs die casting depends on the specific requirements of your project, including the material, volume, complexity, and budget. Understanding these differences will allow you to choose the most appropriate method for your manufacturing needs and ensure that you achieve the desired results with the highest efficiency.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Musica

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness