The Evolving Role of Automotive Moulds in Modern Car Production

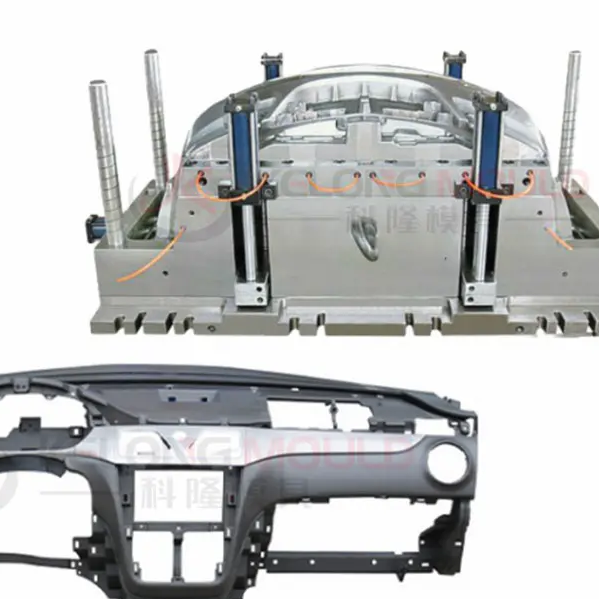

Automotive moulds are integral components in the vehicle manufacturing process, serving as the tools to shape various parts that make up a car. From exterior body panels to internal parts, automotive moulds ensure that components are precisely formed to meet stringent design and performance requirements. Over the years, automotive moulding has evolved significantly, driven by the need for better efficiency, precision, and sustainability in vehicle production.

At its core, automotive moulding involves creating moulds that can withstand the demands of mass production while maintaining a high level of accuracy. These moulds are typically made from durable materials like steel or aluminium and are designed to withstand the pressures and temperatures required to shape various automotive parts. The process can be complex, involving multiple stages, including designing the mould, choosing the right material, and testing its functionality.

One of the key advantages of using automotive moulds in mass production is the ability to produce parts with high consistency. In the past, achieving uniformity across large volumes of parts was a major challenge. Today, advanced moulding technologies, such as injection moulding and die-casting, ensure that each component meets the required specifications, contributing to overall vehicle quality.

In addition to improving consistency, modern moulding techniques have also helped reduce production costs. The ability to create complex shapes without the need for extensive manual labour means that manufacturers can produce parts more quickly and efficiently. As the automotive industry continues to push for faster production timelines and lower costs, moulding solutions are constantly evolving to meet these demands.

Sustainability has also become an important consideration in automotive manufacturing. With growing environmental concerns, there is increasing pressure to reduce the carbon footprint associated with vehicle production. Automotive moulds have a role to play in this shift as more manufacturers explore ways to reduce material waste and energy consumption during the production process. For example, the use of 3D printing in moulding is gaining traction, offering more precise production methods and allowing for better optimization of materials.

Moreover, the development of lighter, stronger materials for both the moulds and the vehicle parts they create has led to further improvements in the efficiency and performance of the final product. As the automotive industry moves toward electric vehicles and autonomous technology, moulding solutions will need to adapt to meet the unique demands of these new types of vehicles. This could include producing components that support advanced battery technologies or creating parts that are lighter and more energy-efficient.

The role of automotive moulds in modern manufacturing is undeniable. As technology continues to advance, the moulding process will likely become even more integrated with other aspects of production, such as digital design and automation. These innovations will continue to shape the future of the automotive industry, contributing to the production of vehicles that are not only more efficient but also better suited to the demands of consumers and the environment.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness