Plastic Bucket Cap Moulds: Precision Engineering for Perfect Fit

Plastic injection moulding is one of the widely used manufacturing processes, particularly for producing precise and durable plastic products such as bucket caps. Bucket caps, commonly used in industries like food packaging, chemicals, and agriculture, require moulds that ensure both functionality and high-quality production. To meet the diverse needs of these applications, several types of plastic injection bucket cap mould are used, each offering unique advantages depending on the specific design requirements and production goals.

A single-cavity mould is designed to produce one bucket cap per cycle. This type of mould is typically used for small production runs or when the design requires high precision in each part. While it may not be the cost-efficient option for high-volume production, single-cavity moulds are ideal when custom, intricate designs are needed, or when working with specialty materials.

Advantages:

High precision and customization for each cap produced.

Ideal for low-volume production or prototyping.

More manageable quality control due to the focus on one cap at a time.

Disadvantages:

Slower production rates compared to multi-cavity moulds.

Not the cost-effective for large-scale manufacturing.

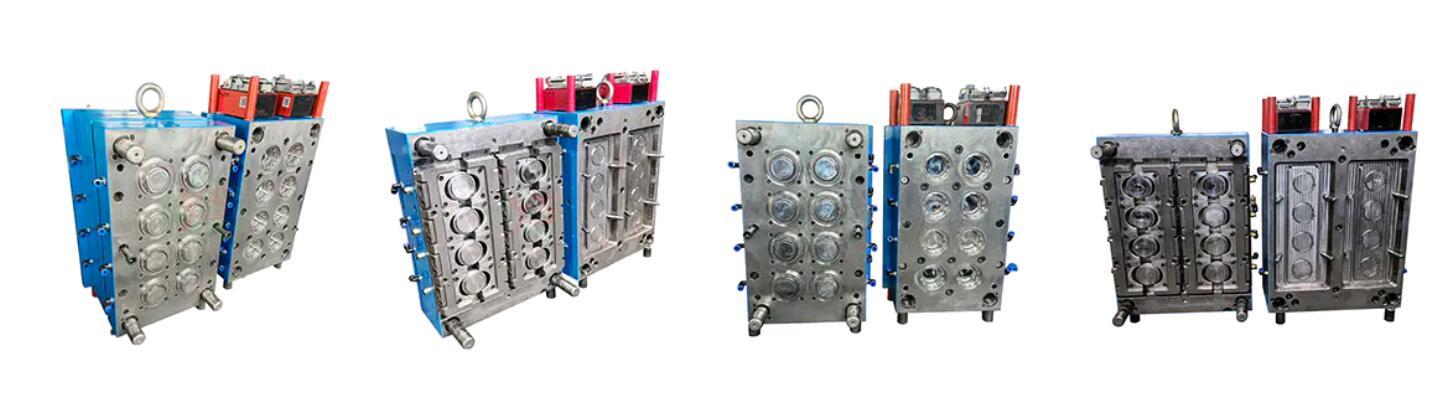

Multi-cavity moulds are designed to produce several bucket caps in a single injection cycle. These moulds feature multiple cavities that are all filled simultaneously, significantly improving production efficiency. Multi-cavity moulds are commonly used in industries that require mass production of standard bucket caps, such as food packaging and industrial chemicals.

Advantages:

Increased production efficiency and throughput.

Cost-effective for large-scale manufacturing due to reduced cycle times.

More consistent quality across all caps produced in each cycle.

Disadvantages:

Higher initial mould investment due to complexity.

Less flexibility in terms of design changes; alterations can be costly.

https://www.ysmou.com/product/cap-mould/plastic-injection-bucket-cap-mould-with-antitheft-ring.html

This type of mould is assembled from outer cap and an inner anti-theft ring. The outer cap is automatically rotated and pushed out by a hydraulic motor, requiring manual installation without much effort.

During the processing, we strictly control each step and test to ensure product quality and delivery time. After each sample is confirmed by the customer for quality, it is arranged for shipment.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Игры

- Gardening

- Health

- Главная

- Literature

- Music

- Networking

- Другое

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness