How Conveyor Belts Streamline Material Handling Processes

A conveyor belt is a crucial part of many industrial systems, used to transport materials from one location to another. Conveyor belts are commonly found in manufacturing, logistics, and mining industries, where they streamline material handling processes, improving productivity and efficiency.

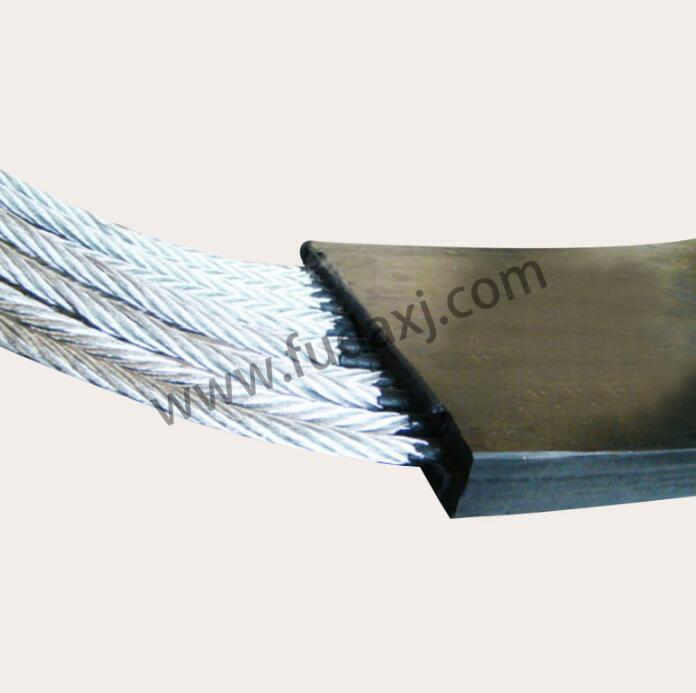

Typically made from durable materials like rubber, PVC, or fabric, conveyor belts are designed to handle various types of materials, from light products to heavy items. The belts are available in a range of sizes, thicknesses, and designs to cater to the specific needs of different applications.

Conveyor belts function by running continuously in a loop, carrying materials along a set path. This movement is powered by pulleys and rollers, which allow for the smooth transfer of goods across long distances. Depending on the application, the conveyor system may be designed for flat or inclined transportation.

The versatility of conveyor belts makes them ideal for a wide range of uses. In the food industry, for instance, belts are used to carry ingredients or finished products through production lines. In mining, they help move mined materials from extraction sites to processing plants.

A major benefit of conveyor belts is their ability to reduce manual labor, thereby increasing efficiency and safety in workplaces. They can be integrated into automated systems to enhance precision and speed, ensuring a consistent flow of materials in production processes.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness