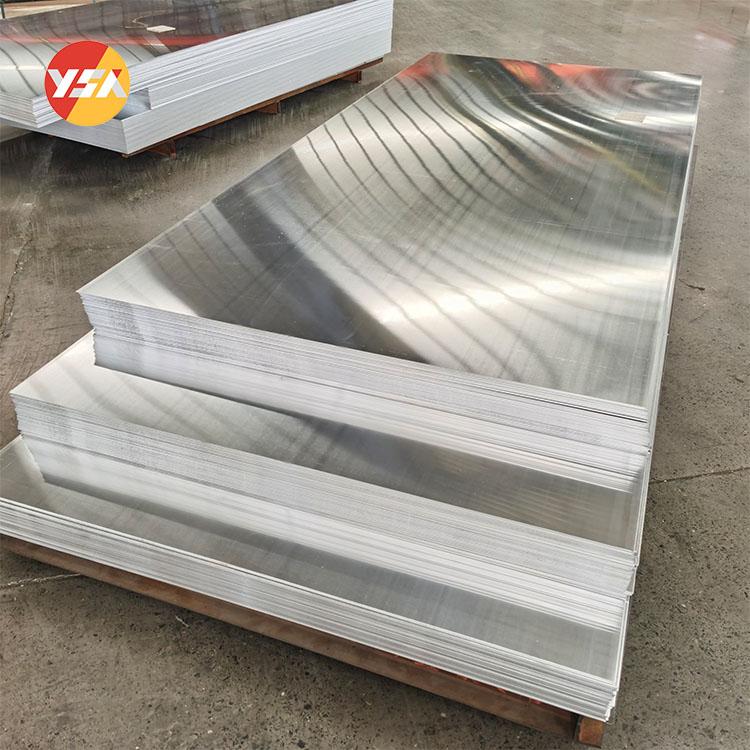

6000 Series Aluminum Alloy: Properties, Applications, and Benefits

Introduction

The 6000 series aluminum alloy is one of the most widely used aluminum alloys, known for its excellent strength, corrosion resistance, and weldability. It is predominantly composed of magnesium (Mg) and silicon (Si), forming magnesium silicide (Mg₂Si), which enhances its mechanical properties.

This article explores the composition, key properties, applications, advantages, and comparisons of 6000 series aluminum alloys, making it essential for industries like construction, automotive, aerospace, and manufacturing.

Composition & Key Alloys in the 6000 Series

The 6000 series is primarily heat-treatable and includes alloys such as:

| Alloy | Composition | Key Properties |

|---|---|---|

| 6061 | Al + Mg (1.0%) + Si (0.6%) + Cu (0.28%) | High strength, excellent corrosion resistance, weldable |

| 6063 | Al + Mg (0.7%) + Si (0.4%) | Excellent extrudability, smooth surface finish |

| 6082 | Al + Mg (0.9%) + Si (1.0%) + Mn (0.7%) | Higher strength than 6061, good machinability |

| 6005 | Al + Mg (0.5%) + Si (0.7%) | Medium strength, used in structural applications |

Key Properties of 6000 Series Aluminum Alloys

6000 series alloys are favored for their balance of strength, workability, and resistance:

1. High Strength-to-Weight Ratio

- Comparable to mild steel but ~1/3 the weight, ideal for lightweight structures.

- Heat-treatable (T6 temper increases strength).

2. Excellent Corrosion Resistance

- Naturally forms an oxide layer, preventing rust.

- Performs well in marine and industrial environments (especially 6061).

3. Good Weldability & Formability

- Suitable for MIG, TIG, and spot welding.

- 6063 is highly extrudable (used in frames and panels).

4. Machinability & Surface Finish

- Easy to cut, drill, and machine (6082 improves chip formation).

- Smooth surface, ideal for anodizing and painting.

Common Applications of 6000 Series Aluminum

Due to its balanced properties, 6000 series alloys are used in:

1. Construction & Architecture

- Window and door frames (6063)

- Bridges, roofing, and structural beams (6082, 6061)

2. Automotive & Transportation

- Car frames, wheel rims (6061-T6)

- Truck chassis and marine components (6082)

3. Aerospace & Defense

- Aircraft landing gear parts (high-strength variants)

- Drone frames and military equipment (lightweight durability)

4. Industrial & Consumer Goods

- Robotic arms, machinery parts (6061, 6005)

- Bicycle frames, sports equipment (lightweight performance)

Advantages Over Other Aluminum Series

| Feature | 6000 Series | 2000 (Aircraft) | 5000 (Marine) | 7000 (High-Strength) |

|---|---|---|---|---|

| Strength | Medium-High | Very High | Medium | Highest |

| Corrosion Resistance | Excellent | Poor | Best | Moderate |

| Machinability | Good | Poor | Good | Fair |

| Weldability | Best | Poor | Good | Poor |

Best for: Structural uses requiring weldability, corrosion resistance, and medium-high strength.

Conclusion: Why Choose 6000 Series Aluminum?

The 6000 series is the optimal choice for:

✔ Lightweight yet strong structures

✔ High corrosion-resistant applications

✔ Precision welding & machining needs

Its versatility in construction, automotive, and aerospace makes it a top material for engineers and manufacturers worldwide.

Frequently Asked Questions (FAQ)

Which is stronger, 6061 or 6082 aluminum?

- 6082 has slightly higher strength due to increased silicon and manganese, making it ideal for structural applications.

Does 6000 series aluminum rust?

- No, it forms a protective oxide layer, making it highly corrosion-resistant.

Can 6000 series aluminum be heat-treated?

- Yes, T6 tempering significantly boosts hardness and strength.

What’s the best alloy for extrusion?

- 6063 is the best for extrusion due to its smooth finish and excellent formability.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Oyunlar

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness