laser equipment

https://martlaser.com/

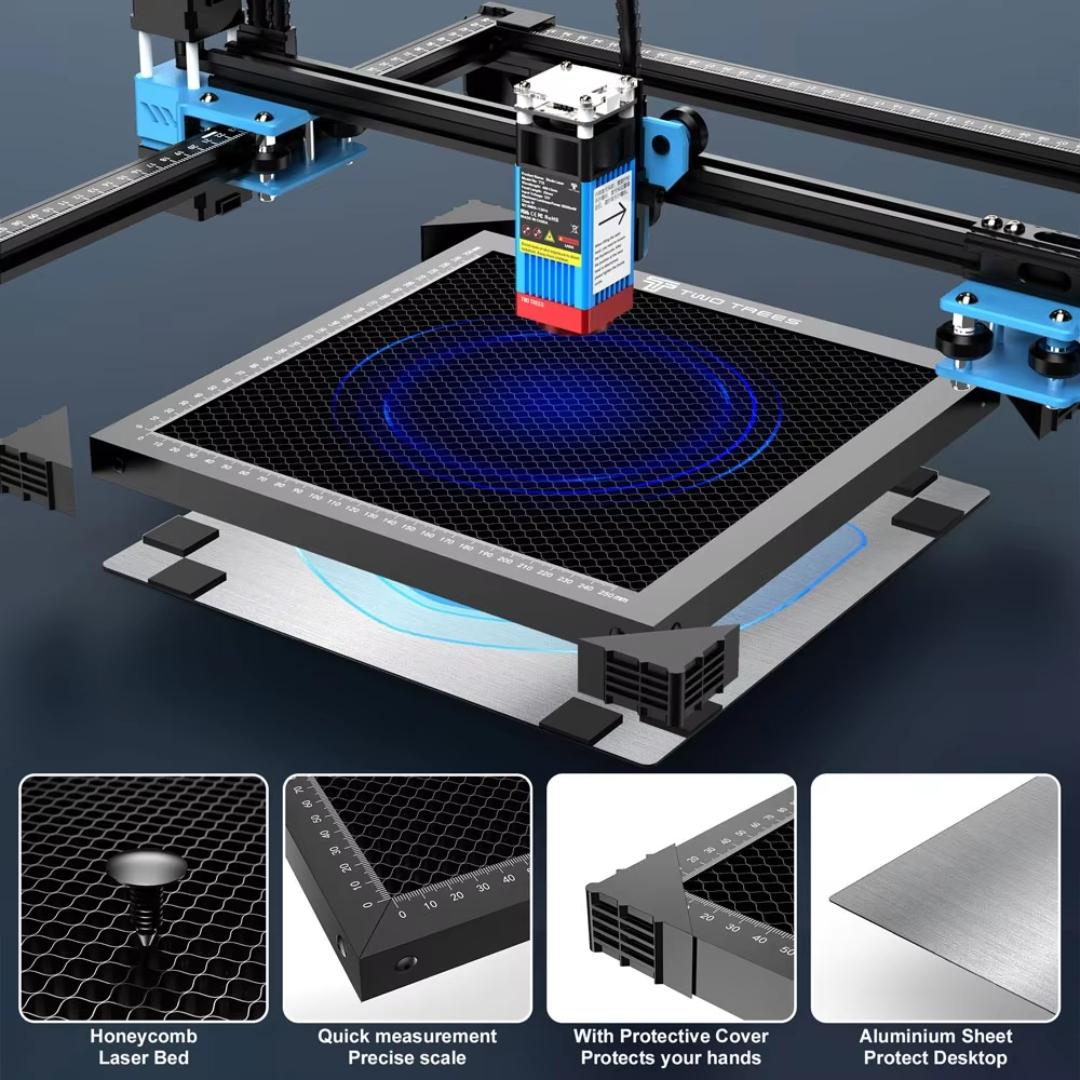

Discover high-performance laser equipment designed for precision and efficiency in industrial and creative applications. Perfect for cutting, engraving, marking, and more, our advanced machines deliver unmatched accuracy and reliability for professionals worldwide.

#LaserEquipment #LaserTech #EngravingMachine #LaserCutting #IndustrialLaser #PrecisionTools #LaserMarking #CuttingEdgeTech #MachineryTools #LaserSolutions

https://martlaser.com/

Discover high-performance laser equipment designed for precision and efficiency in industrial and creative applications. Perfect for cutting, engraving, marking, and more, our advanced machines deliver unmatched accuracy and reliability for professionals worldwide.

#LaserEquipment #LaserTech #EngravingMachine #LaserCutting #IndustrialLaser #PrecisionTools #LaserMarking #CuttingEdgeTech #MachineryTools #LaserSolutions

laser equipment

https://martlaser.com/

Discover high-performance laser equipment designed for precision and efficiency in industrial and creative applications. Perfect for cutting, engraving, marking, and more, our advanced machines deliver unmatched accuracy and reliability for professionals worldwide.

#LaserEquipment #LaserTech #EngravingMachine #LaserCutting #IndustrialLaser #PrecisionTools #LaserMarking #CuttingEdgeTech #MachineryTools #LaserSolutions

0 Comentários

0 Compartilhamentos

294 Visualizações