Un po' di geografia economica.

Ucraina

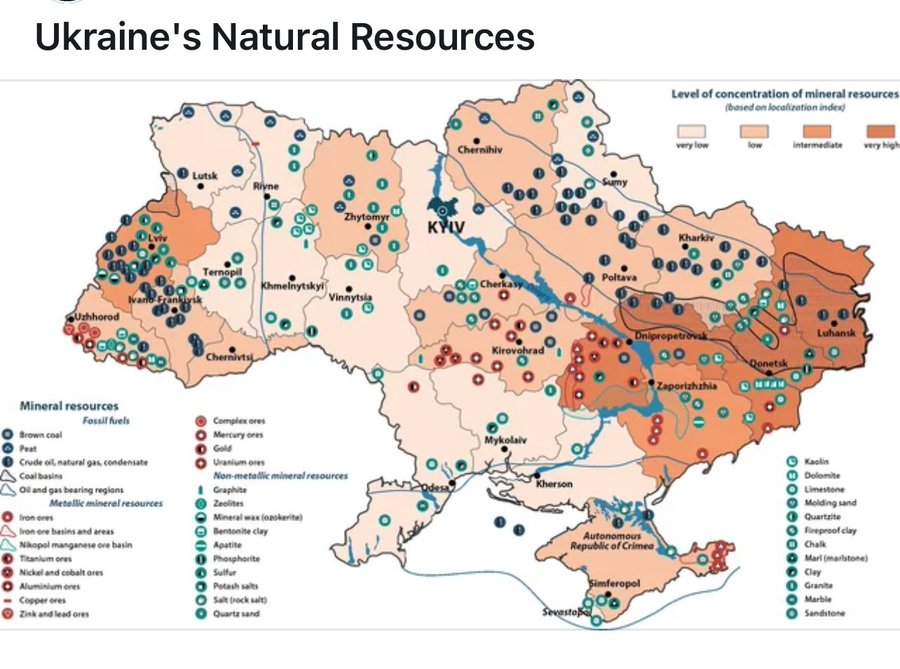

Il valore stimato dei suoi minerali essenziali, ovvero le terre rare, supera i 26 trilioni di dollari.

Minerale di ferro: l'Ucraina possiede alcune delle più grandi riserve di minerale di ferro del mondo, stimate in 27,4 miliardi di tonnellate. Le prime 10 al mondo

Manganese: il paese possiede notevoli riserve di manganese, in particolare nel bacino di Nikopol, il che lo rende uno dei principali produttori a livello mondiale.

Titanio: l'Ucraina detiene le maggiori riserve di titanio in Europa, pari al 7% delle riserve mondiali.

Grafite: con circa 300 giacimenti, l'Ucraina è al secondo posto a livello mondiale per riserve di grafite, detenendo circa il 20% del totale mondiale.

Uranio: il Paese possiede notevoli riserve di uranio, stimate in 45,6 mila tonnellate, pari all'1,8% del totale mondiale.

Carbone: le riserve di carbone dell'Ucraina sono ingenti, con stime che si aggirano intorno ai 34 miliardi di tonnellate, il che la rende la settima riserva di carbone più grande al mondo e la seconda in Europa.

Petrolio e gas naturale: il paese possiede notevoli giacimenti di petrolio e gas, con riserve pari a circa 138 milioni di tonnellate di petrolio e 1.118 miliardi di metri cubi di gas naturale.

Ma a noi di tutta questa roba non interessa nulla.

A noi interessa solo difendere la sua democrazia.

A bit of economic geography.

Ukraine

The estimated value of its essential minerals, rare earths, exceeds $26 trillion.

Iron ore: Ukraine has some of the world's largest iron ore reserves, estimated at 27.4 billion tonnes. Top 10 in the world

Manganese: The country has significant reserves of manganese, particularly in the Nikopol Basin, making it one of the world's leading producers.

Titanium: Ukraine has the largest titanium reserves in Europe, accounting for 7% of the world's reserves.

Graphite: With around 300 deposits, Ukraine is the world's second largest in graphite reserves, holding around 20% of the world's total.

Uranium: The country has significant uranium reserves, estimated at 45.6 thousand tonnes, or 1.8% of the world's total.

Coal: Ukraine’s coal reserves are huge, estimated at around 34 billion tons, making it the seventh largest coal reserve in the world and the second largest in Europe.

Oil and Natural Gas: The country has significant oil and gas reserves, with reserves of around 138 million tons of oil and 1,118 billion cubic meters of natural gas.

But we don’t care about any of that stuff.

We only care about defending its democracy.

Ucraina

Il valore stimato dei suoi minerali essenziali, ovvero le terre rare, supera i 26 trilioni di dollari.

Minerale di ferro: l'Ucraina possiede alcune delle più grandi riserve di minerale di ferro del mondo, stimate in 27,4 miliardi di tonnellate. Le prime 10 al mondo

Manganese: il paese possiede notevoli riserve di manganese, in particolare nel bacino di Nikopol, il che lo rende uno dei principali produttori a livello mondiale.

Titanio: l'Ucraina detiene le maggiori riserve di titanio in Europa, pari al 7% delle riserve mondiali.

Grafite: con circa 300 giacimenti, l'Ucraina è al secondo posto a livello mondiale per riserve di grafite, detenendo circa il 20% del totale mondiale.

Uranio: il Paese possiede notevoli riserve di uranio, stimate in 45,6 mila tonnellate, pari all'1,8% del totale mondiale.

Carbone: le riserve di carbone dell'Ucraina sono ingenti, con stime che si aggirano intorno ai 34 miliardi di tonnellate, il che la rende la settima riserva di carbone più grande al mondo e la seconda in Europa.

Petrolio e gas naturale: il paese possiede notevoli giacimenti di petrolio e gas, con riserve pari a circa 138 milioni di tonnellate di petrolio e 1.118 miliardi di metri cubi di gas naturale.

Ma a noi di tutta questa roba non interessa nulla.

A noi interessa solo difendere la sua democrazia.

A bit of economic geography.

Ukraine

The estimated value of its essential minerals, rare earths, exceeds $26 trillion.

Iron ore: Ukraine has some of the world's largest iron ore reserves, estimated at 27.4 billion tonnes. Top 10 in the world

Manganese: The country has significant reserves of manganese, particularly in the Nikopol Basin, making it one of the world's leading producers.

Titanium: Ukraine has the largest titanium reserves in Europe, accounting for 7% of the world's reserves.

Graphite: With around 300 deposits, Ukraine is the world's second largest in graphite reserves, holding around 20% of the world's total.

Uranium: The country has significant uranium reserves, estimated at 45.6 thousand tonnes, or 1.8% of the world's total.

Coal: Ukraine’s coal reserves are huge, estimated at around 34 billion tons, making it the seventh largest coal reserve in the world and the second largest in Europe.

Oil and Natural Gas: The country has significant oil and gas reserves, with reserves of around 138 million tons of oil and 1,118 billion cubic meters of natural gas.

But we don’t care about any of that stuff.

We only care about defending its democracy.

Un po' di geografia economica.

Ucraina

Il valore stimato dei suoi minerali essenziali, ovvero le terre rare, supera i 26 trilioni di dollari.

Minerale di ferro: l'Ucraina possiede alcune delle più grandi riserve di minerale di ferro del mondo, stimate in 27,4 miliardi di tonnellate. Le prime 10 al mondo

Manganese: il paese possiede notevoli riserve di manganese, in particolare nel bacino di Nikopol, il che lo rende uno dei principali produttori a livello mondiale.

Titanio: l'Ucraina detiene le maggiori riserve di titanio in Europa, pari al 7% delle riserve mondiali.

Grafite: con circa 300 giacimenti, l'Ucraina è al secondo posto a livello mondiale per riserve di grafite, detenendo circa il 20% del totale mondiale.

Uranio: il Paese possiede notevoli riserve di uranio, stimate in 45,6 mila tonnellate, pari all'1,8% del totale mondiale.

Carbone: le riserve di carbone dell'Ucraina sono ingenti, con stime che si aggirano intorno ai 34 miliardi di tonnellate, il che la rende la settima riserva di carbone più grande al mondo e la seconda in Europa.

Petrolio e gas naturale: il paese possiede notevoli giacimenti di petrolio e gas, con riserve pari a circa 138 milioni di tonnellate di petrolio e 1.118 miliardi di metri cubi di gas naturale.

Ma a noi di tutta questa roba non interessa nulla.

A noi interessa solo difendere la sua democrazia.

A bit of economic geography.

Ukraine

The estimated value of its essential minerals, rare earths, exceeds $26 trillion.

Iron ore: Ukraine has some of the world's largest iron ore reserves, estimated at 27.4 billion tonnes. Top 10 in the world

Manganese: The country has significant reserves of manganese, particularly in the Nikopol Basin, making it one of the world's leading producers.

Titanium: Ukraine has the largest titanium reserves in Europe, accounting for 7% of the world's reserves.

Graphite: With around 300 deposits, Ukraine is the world's second largest in graphite reserves, holding around 20% of the world's total.

Uranium: The country has significant uranium reserves, estimated at 45.6 thousand tonnes, or 1.8% of the world's total.

Coal: Ukraine’s coal reserves are huge, estimated at around 34 billion tons, making it the seventh largest coal reserve in the world and the second largest in Europe.

Oil and Natural Gas: The country has significant oil and gas reserves, with reserves of around 138 million tons of oil and 1,118 billion cubic meters of natural gas.

But we don’t care about any of that stuff.

We only care about defending its democracy.