Quality Control in Motor Core Stamping: Ensuring Precision and Reliability

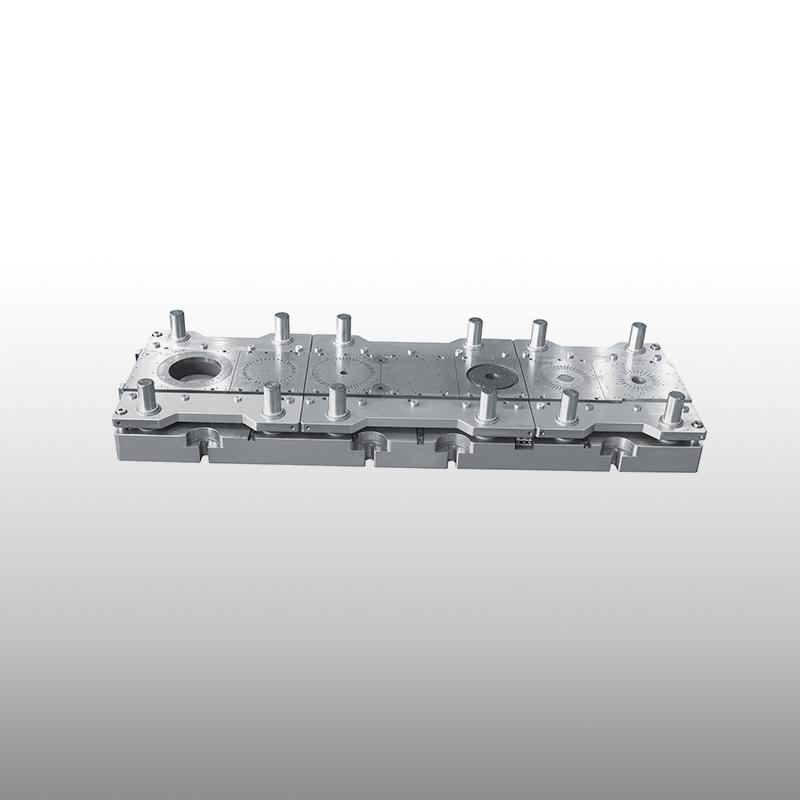

The motor core stamping process involves the fabrication of stator and rotor cores, which are essential components in electric motors. Given the complexity of these components, maintaining high-quality standards throughout the stamping process is crucial. Quality control begins with the selection of raw materials, which must meet specific criteria to ensure they can withstand the demands of the final application. The properties of the materials used in motor core stamping directly affect the performance and efficiency of the motor, making material inspection a fundamental step in the quality assurance process.

Search

Nach Verein filtern

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Startseite

- Literature

- Musik

- Networking

- Andere

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Weiterlesen

Bakery Premixes Market Application, and Trend during 2022 to 2029

Meticulous Research®—a leading global market research company, published a research...

FC 25: Full List of New Teams and Who's Out

Introduction

With the 2023/24 season drawing to a close, the lineup for FC 25 is...

Automotive Glazing Market:

Automotive Glazing Market: Driving Innovation in Vehicle Design and Safety

The automotive...

Mastering the Diablo II Horadric Cube: A Comprehensive Guide to Crafting Powerful Weapons and Utilizing D2R Runes

Mastering the Diablo II Horadric Cube: A Comprehensive Guide to Crafting Powerful Weapons and...

Lip Gloss Sample Containers Are Suitable for Trial and Travel-Size Packaging

The versatility of lip gloss sample containers is another reason for their popularity....

© 2025 Scenario.press - libera espressione

Deutsch

Deutsch