Quality Control in Motor Core Stamping: Ensuring Precision and Reliability

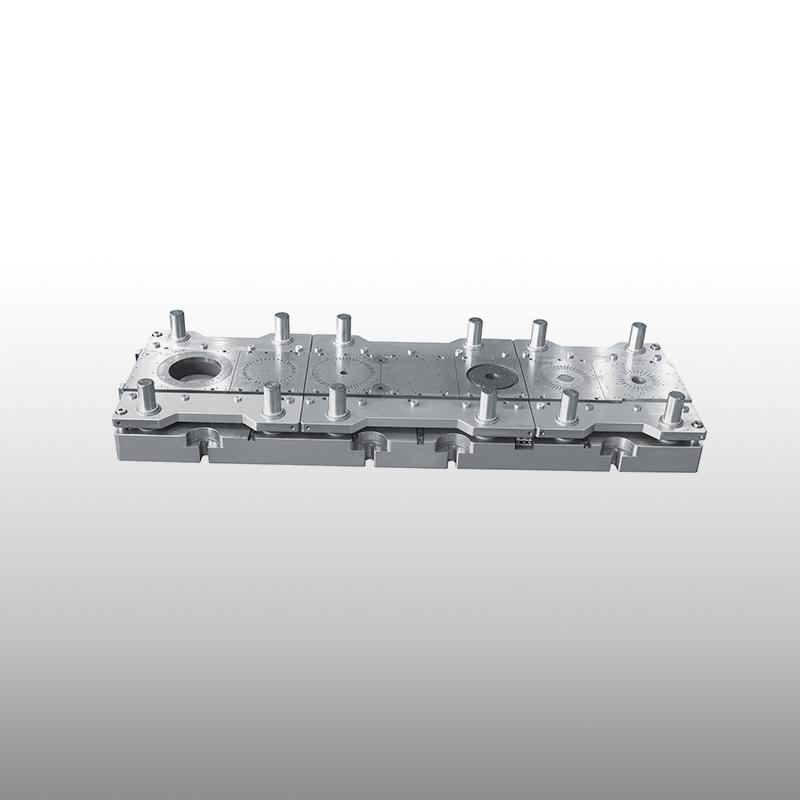

The motor core stamping process involves the fabrication of stator and rotor cores, which are essential components in electric motors. Given the complexity of these components, maintaining high-quality standards throughout the stamping process is crucial. Quality control begins with the selection of raw materials, which must meet specific criteria to ensure they can withstand the demands of the final application. The properties of the materials used in motor core stamping directly affect the performance and efficiency of the motor, making material inspection a fundamental step in the quality assurance process.

Buscar

Categorías

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Juegos

- Gardening

- Health

- Inicio

- Literature

- Music

- Networking

- Otro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Leer más

**Titre : Acheter Crédits FIFA 25 : Guide Complet pour Maximiser vos Crédits FC25 et Améliorer votre Équipe dans FIFA**

Acheter Crédits FIFA 25 : Guide Complet pour Maximiser vos Crédits FC25 et...

Cockburn leads No. 12 Illinois versus No. 19 Michigan State after 20-point video game

Illinois Fighting Illini at Michigan State SpartansEast Lansing, Michigan; Saturday, 12 p....

Switzerland Electric Commercial Vehicle Market Growth, Trends, and Future Prospects

The Switzerland electric commercial vehicle market is experiencing significant growth, driven by...

Foundry Coke Market Trending Strategies and Analysis Forecast by 2031

The market research study titled “Foundry Coke Market Share, Trends, and Outlook |...

Understanding HDPE Bags: Applications, Benefits, and Environmental Impact

In today’s world, plastic packaging plays a crucial role in various industries, from...

© 2025 Scenario.press - libera espressione

Spanish

Spanish