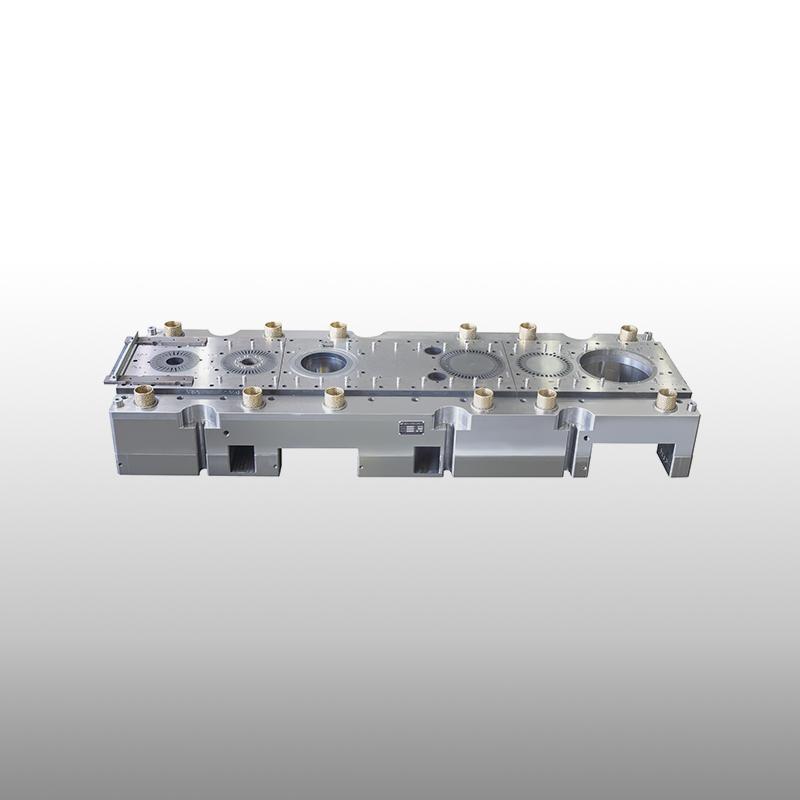

Custom Core Lamination Stamping Factory

The core lamination stamping process doesn't end with the lamination and curing stages. After the core is formed, it is typically subjected to quality control checks to ensure that it meets the specifications required for its intended application. These checks might include testing for dimensional accuracy, magnetic properties, and overall structural integrity. Any core that fails these tests is either discarded or sent for rework to correct any defects. This attention to detail ensures that the final product performs as expected in its application, be it in an electrical motor, transformer, or another electromagnetic device.

البحث

الأقسام

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- الألعاب

- Gardening

- Health

- الرئيسية

- Literature

- Music

- Networking

- أخرى

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

إقرأ المزيد

Where to Buy Cheap Path of Exile 2 Gold: Your Ultimate Guide to Affordable In-Game Currency for Sale

Where to Buy Cheap Path of Exile 2 Gold: Your Ultimate Guide to Affordable In-Game Currency for...

How to Connect Dahua NVR to Mobile App in Bangladesh

In Bangladesh, Dahua NVR systems are popular for providing reliable video surveillance solutions....

Unlocking Monopoly Go: Free PEG E Links, Monopoly Card Insights, and Board Costs Explained

Unlocking Monopoly Go: Free PEG E Links, Monopoly Card Insights, and Board Costs Explained...

Guía Completa para Comprar Jugadores en FC 25: Precios y Estrategias Efectivas

Guía Completa para Comprar Jugadores en FC 25: Precios y Estrategias Efectivas

Si eres un...

Automated External Defibrillators Market, Demand In Depth Studies With Top Vendors by Fact MR

The global automated external defibrillator market is expected to be worth US$ 17 Billion in...

© 2025 Scenario.press - libera espressione

Arabic

Arabic