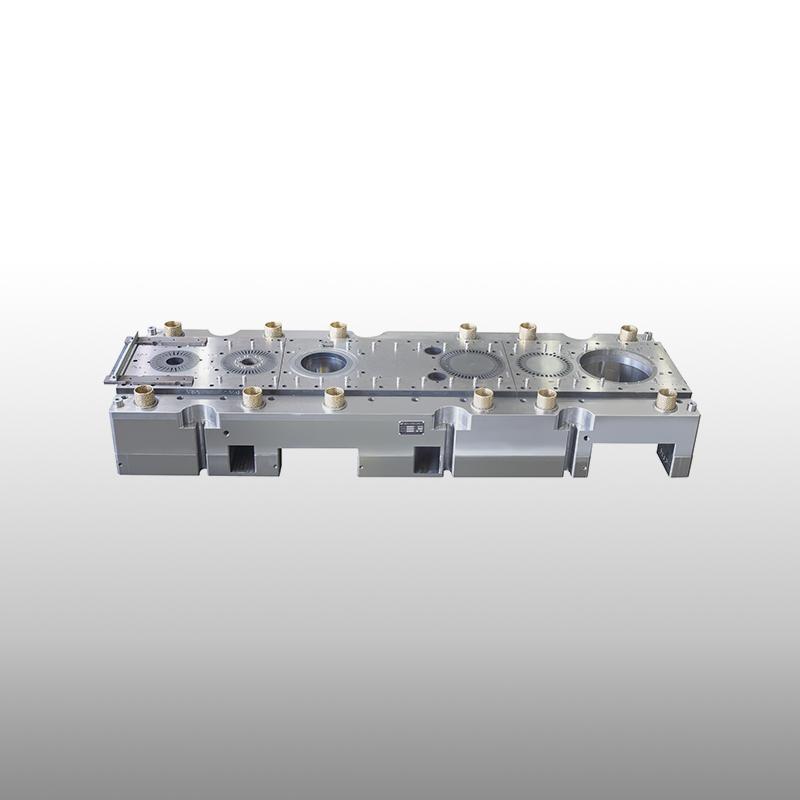

Custom Core Lamination Stamping Factory

The core lamination stamping process doesn't end with the lamination and curing stages. After the core is formed, it is typically subjected to quality control checks to ensure that it meets the specifications required for its intended application. These checks might include testing for dimensional accuracy, magnetic properties, and overall structural integrity. Any core that fails these tests is either discarded or sent for rework to correct any defects. This attention to detail ensures that the final product performs as expected in its application, be it in an electrical motor, transformer, or another electromagnetic device.

Rechercher

Catégories

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Lire la suite

Exploring the Features of Next-Generation Smart Cooktops

A smart cooktop typically incorporates connectivity features that allow it to communicate with...

《颜心记》:跨越时间的爱情与命运

肥猫TV《颜心记》于2024年上映,带着浓郁的情感与复杂的命运故事,吸引了众多观众的目光。这部剧通过精致的叙事、深刻的人物刻画以及绚丽的视觉效果,呈现出一段跨越时间的爱情故事。...

Romania Automotive Seat Heater Market Trends, Challenges, and Future Outlook

Romania automotive diagnostic tool market is expanding, fueled by the growing automotive industry...

Guida Completa per Comprare Crediti FIFA 25: I Vantaggi delle FIFA Coins e Come Ottimizzare il Tuo Team in FC 25

Guida Completa per Comprare Crediti FIFA 25: I Vantaggi delle FIFA Coins e Come Ottimizzare il...

Ghana DG Set Market Share, Growing Demand, and Top Key Players

It has not been much time when several households in Ghana experienced a power-cut in the month...

© 2025 Scenario.press - libera espressione

French

French