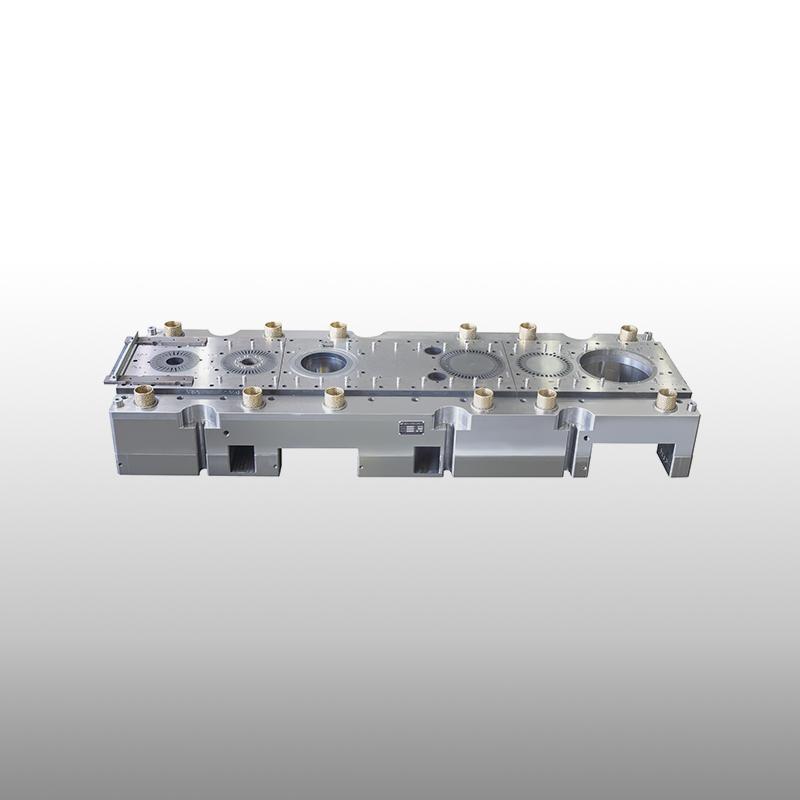

Custom Core Lamination Stamping Factory

The core lamination stamping process doesn't end with the lamination and curing stages. After the core is formed, it is typically subjected to quality control checks to ensure that it meets the specifications required for its intended application. These checks might include testing for dimensional accuracy, magnetic properties, and overall structural integrity. Any core that fails these tests is either discarded or sent for rework to correct any defects. This attention to detail ensures that the final product performs as expected in its application, be it in an electrical motor, transformer, or another electromagnetic device.

Поиск

Категории

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Игры

- Gardening

- Health

- Главная

- Literature

- Music

- Networking

- Другое

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Больше

The Role of Reciprocating Saws in Demolition and Construction Projects

Heavy duty reciprocating saws are indispensable tools in the construction and demolition...

Technical Textile Market, Demand May Set New Growth Story by Fact MR

Projected to expanding at a CAGR of 5.3%, the global technical textile market size is forecasted...

Austria Automated Guided Vehicle Market Strategies for Growth and Technological Advancement by 2032

Austria Automated Guided Vehicle Market Overview

The Austria automated guided vehicle...

Frozen Meat Slicer Market: Trends, Opportunities, and Growth Insights 2032

The Frozen Meat Slicer market research report offers a thorough examination of the present market...

From Leaf to Cup: Understanding the Tea Supply Chain and Its Challenges

The global tea market, valued at US$ 20.2 billion in 2023, is projected to grow at a compound...

© 2025 Scenario.press - libera espressione

Russian

Russian