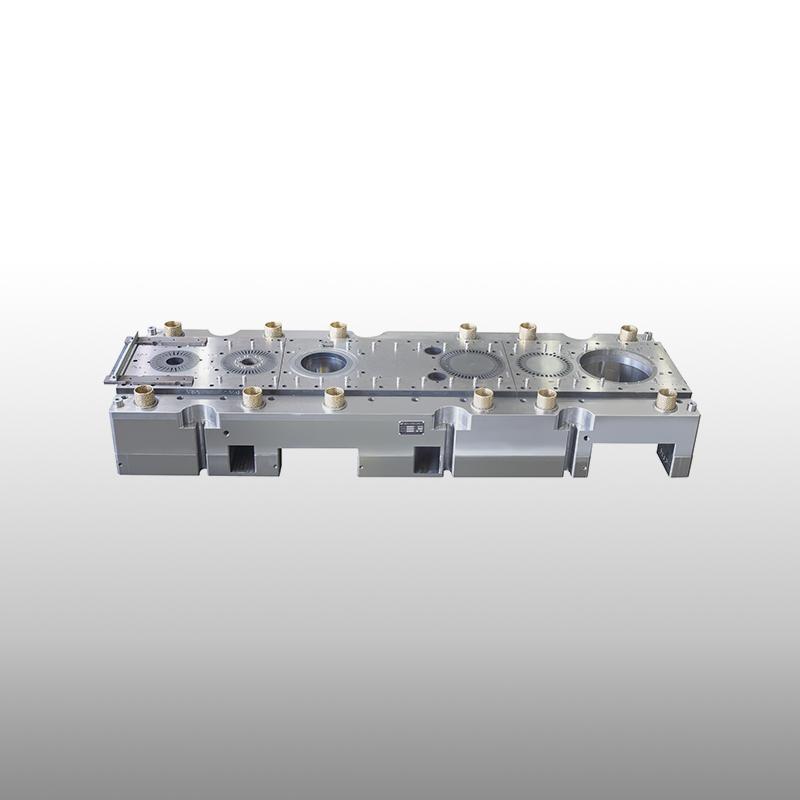

Custom Core Lamination Stamping Factory

The core lamination stamping process doesn't end with the lamination and curing stages. After the core is formed, it is typically subjected to quality control checks to ensure that it meets the specifications required for its intended application. These checks might include testing for dimensional accuracy, magnetic properties, and overall structural integrity. Any core that fails these tests is either discarded or sent for rework to correct any defects. This attention to detail ensures that the final product performs as expected in its application, be it in an electrical motor, transformer, or another electromagnetic device.

Search

Categories

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Read More

Snovitra Super Power: Raises Sensual Performance with A Perfect Remedy

Sensual dysfunction is a common issue among men. It influences men of all age groups. This...

Guida Completa per Comprare Crediti FIFA 25: Crediti FC 25 e Come Ottenerli in Modo Sicuro

Guida Completa per Comprare Crediti FIFA 25: Crediti FC 25 e Come Ottenerli in Modo Sicuro

Se...

**Optimisez votre expérience de jeu avec le Crédit FC25 et le Credit FIFA 25**

Optimisez votre expérience de jeu avec le Crédit FC25 et le Credit FIFA 25

Dans le...

Australia Hybrid Power Solution Market Trends, Opportunities, and Challenges

Australia hybrid power solution market is growing as industries and remote communities seek...

Acheter des Crédits FIFA 25 Rapides et Profiter de Remises Exclusives sur Xbox Series

Acheter des Crédits FIFA 25 Rapides et Profiter de Remises Exclusives sur Xbox Series...

© 2025 Scenario.press - libera espressione

English

English